Section04ENGINE

Subsection 02 (ENGINE LEAK TEST AND DIMENSION MEASUREMENT)

ENGINE LEAK TEST AND DIMENSION

MEASUREMENT

LEAK TEST

The following gives verification procedures for 593

and 793 types of engines.

PREPARATION

– Remove tuned pipe.

– Install plug over exhaust manifold.

– Remove carburetors/throttle body assembly (as

applicable).

– Unplug fuel inlet line from fuel rail.

– Insert plugs in intake rubber boots. Tighten

with existing clamps.

A33C19A

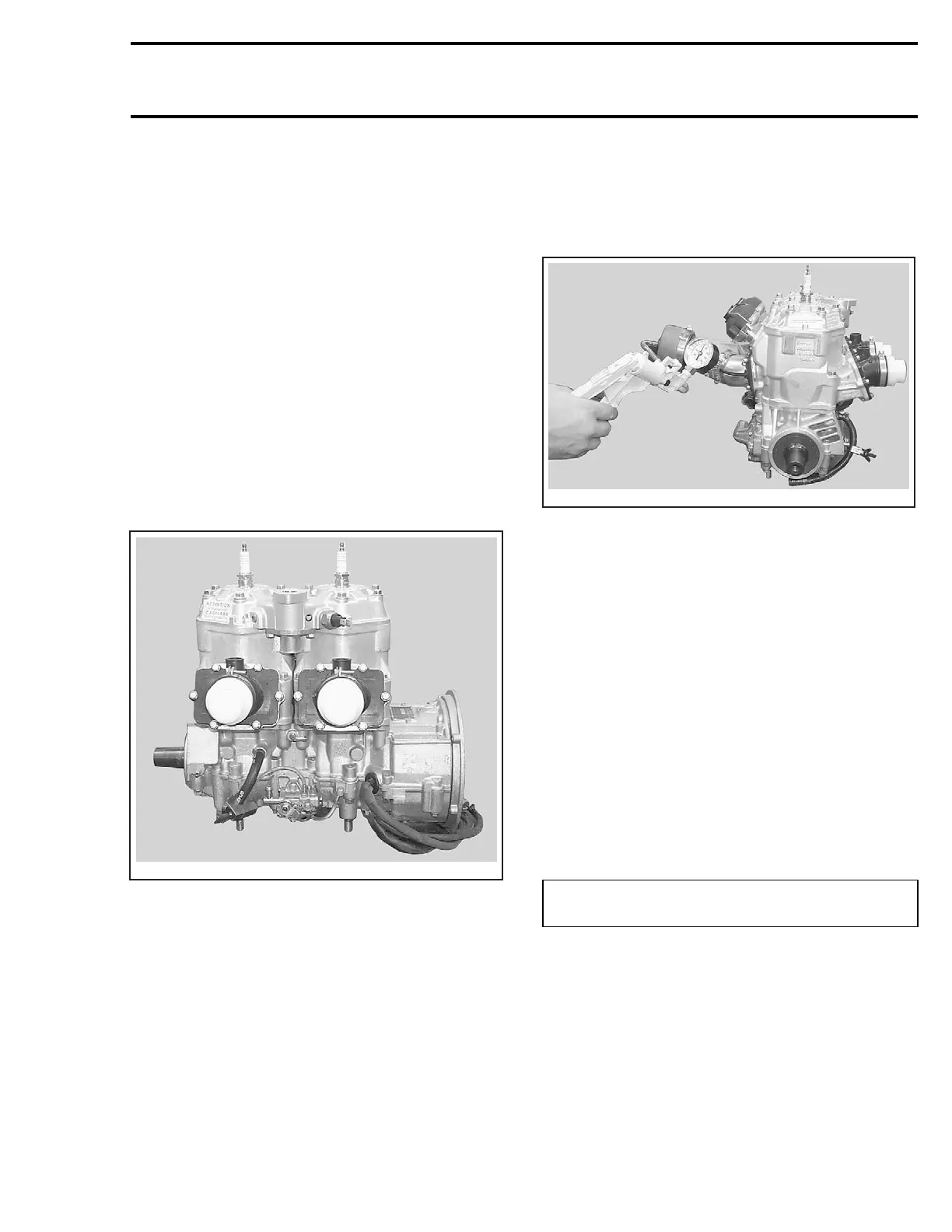

– Using a hose pincher (P/N 295 000 076), block

impulse hose.

– Install air pump on exhaust plug.

NOTE: If necessary, lubricate air pump piston with

mild soap.

CAUTION: Using hydrocarbon lubricant (such

as engine oil) will damage rubber seal of pump

piston.

A33C1AA

– Activate pump and pressurize engine to 34 kPa

(5 PSI). Do not exceed this pressure.

– Engine must stand this pressure during 3 min-

utes. If pressure drops before 3 minutes, check

tester kit by spraying a soapy solution on pump

cylinder, all plugs and fittings.

• If tester kit is leaking, bubbles will indicate

where leak comes from.

• If tester kit is not leaking, check engine as per

following procedure.

PROCEDURE

NOTE: A flow chart has been prepared as a visual

reference. See last page of this chapter.

Using flow chart and following text, pressurize

area to be tested and spray soapy solution at the

indicated location.

TEST PRESSURE: 34 kPa (5 PSI)

for 3 minutes

• If there is a leak at the tested location, it is

recommended to continue testing next items

before overhauling engine. There is a possi-

bility of more than one leak.

• If there is no leak at the tested location, con-

tinue pumping to maintain pressure and con-

tinue with next items until leak is found.

mmr2004-Rev 111

Loading...

Loading...