Section04ENGINE

Subsection 02 (ENGINE LEAK TEST AND DIMENSION MEASUREMENT)

Engine

Check the following:

– All jointed surfaces and screw/stud threads of

engine:

• spark plug base, insulator

• cylinder head

• RAVE valve bellows, piston and housing

• cylinder crankcase halves (joint)

• oil injection pump mounting flange (O-ring)

• coolant pump housing

• bleed screws/plugs

• crankcase grease reservoir fitting.

– Small injection oil lines coming from pump.

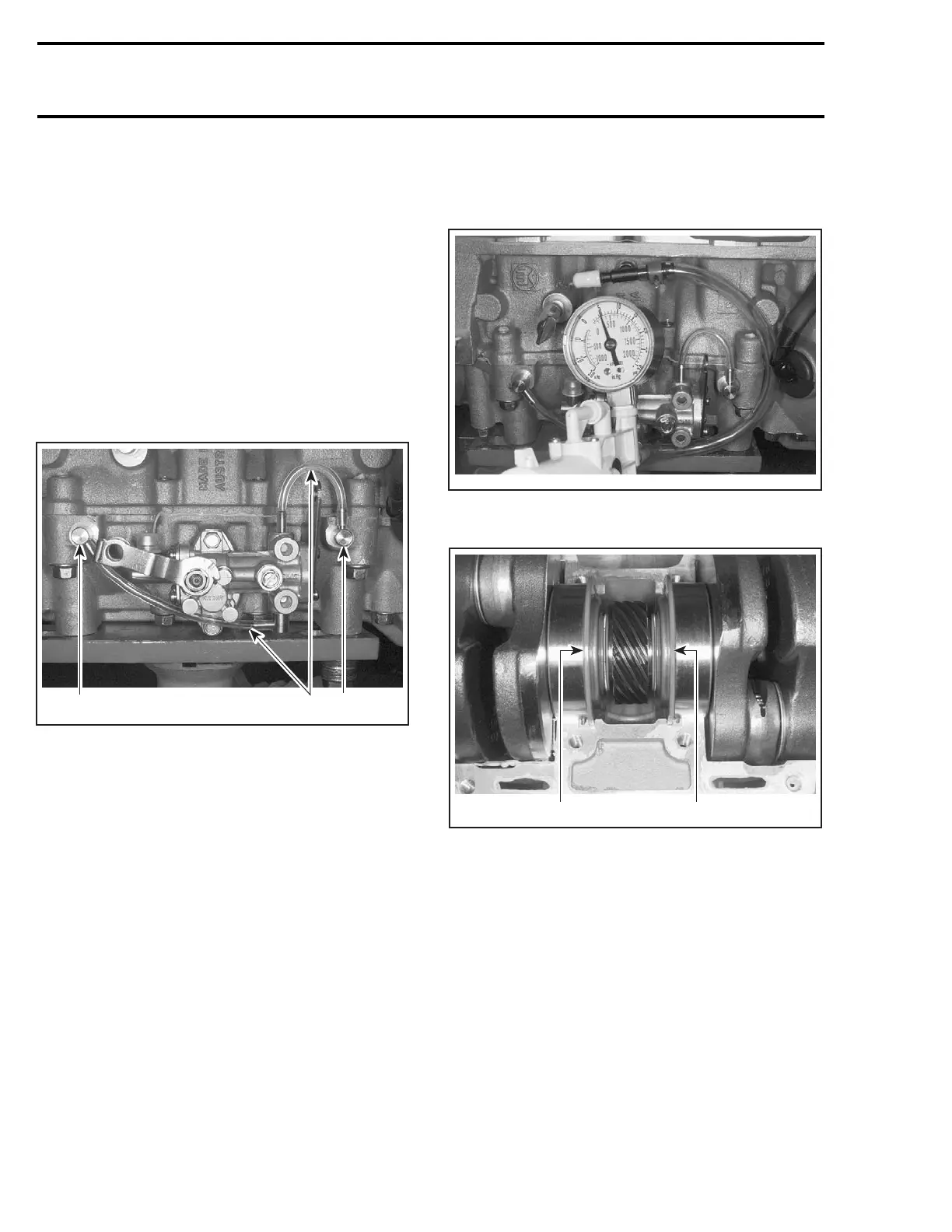

A32C1GA

1

2

1

TYPICAL

1. Injection nipples

2. Small injection oil lines

Check for air bubbles or oil column going toward

pump. It indicates defective check valve in injec-

tion nipples.

– Remove cooling system cap.

Check for air bubbles in antifreeze. It indicates de-

fective cylinder head O-ring or cylinder base gas-

ket.

– Remove drive pulley then check crankshaft

outer seal.

– Remove rewind starter and magneto system

then check crankshaft outer seal.

– Check pump shaft gear oil reservoir.

Pump Shaft Oil Gear Reservoir

Install air pump on adapter and pressurize as

above.

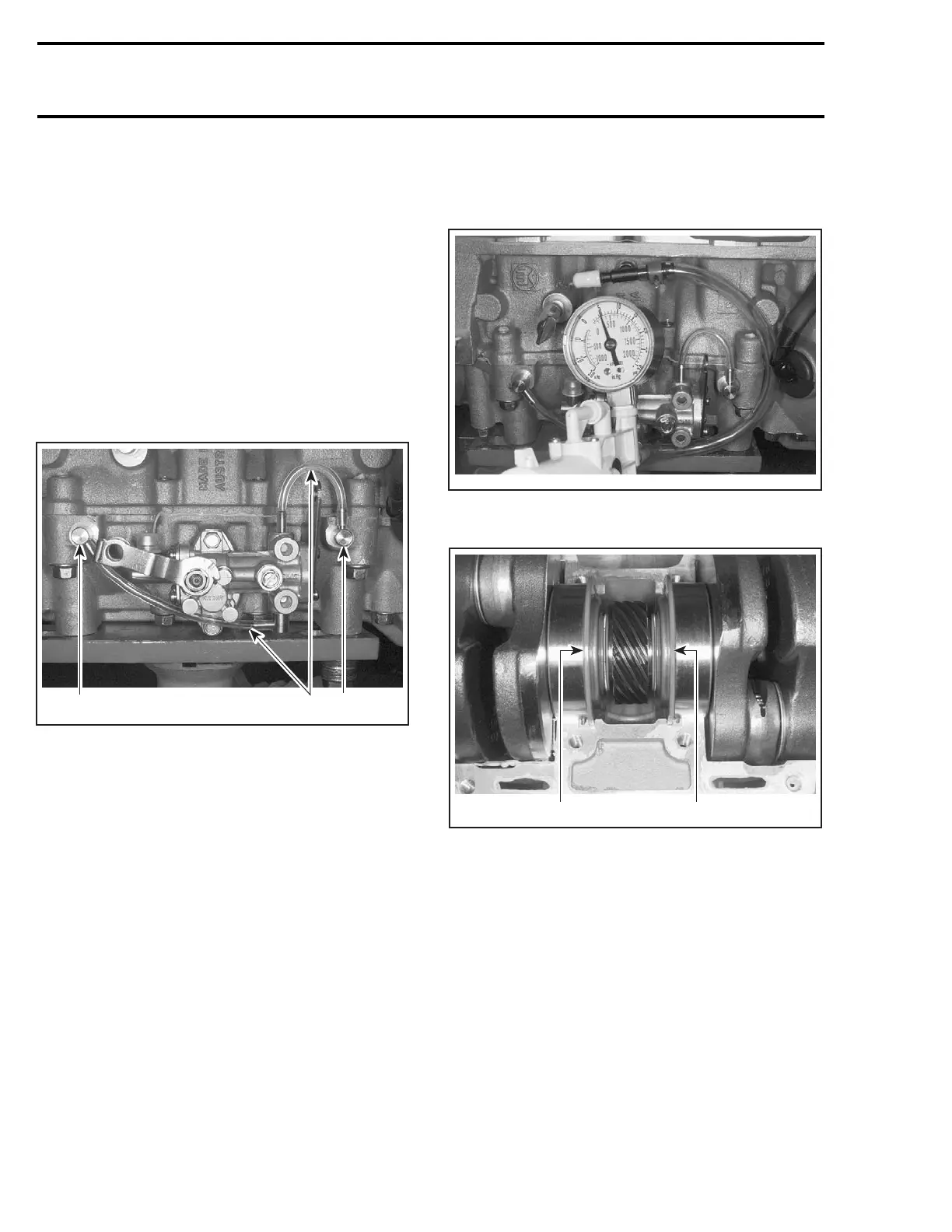

A32C1HA

If pressure drops, it indicates a defective crank-

shaft inner seal.

2

A32C1IA

1

TYPICAL — CRANKSHAFT INSTALLED IN UPPER

HALF CRANKCASE

1. Crankshaft inner seal on PTO side

2. Crankshaft inner seal on MAG side

112 mmr2004-Rev

Loading...

Loading...