111

3. Check that when the valve is opened that at its next complete revolution,

the stop arm clears the top of the stop screw and that on closing, it

engages fi rmly with the stop screw. If not, the screw may be adjusted by

slackening its lock nut and screwing the stop in or out to achieve this.

4. Carry out a full check of the hypoxic guard calibration as described in

Chapter 4.

Small variations from the specifi ed Basal fl ow can usually be rectifi ed using the

above method. If this does not give a satisfactory result, it is possible that, if the

fl ow had been shut off completely, the valve seat may have been damaged. In

these cases, you may need to replace the block with a new calibrated unit.

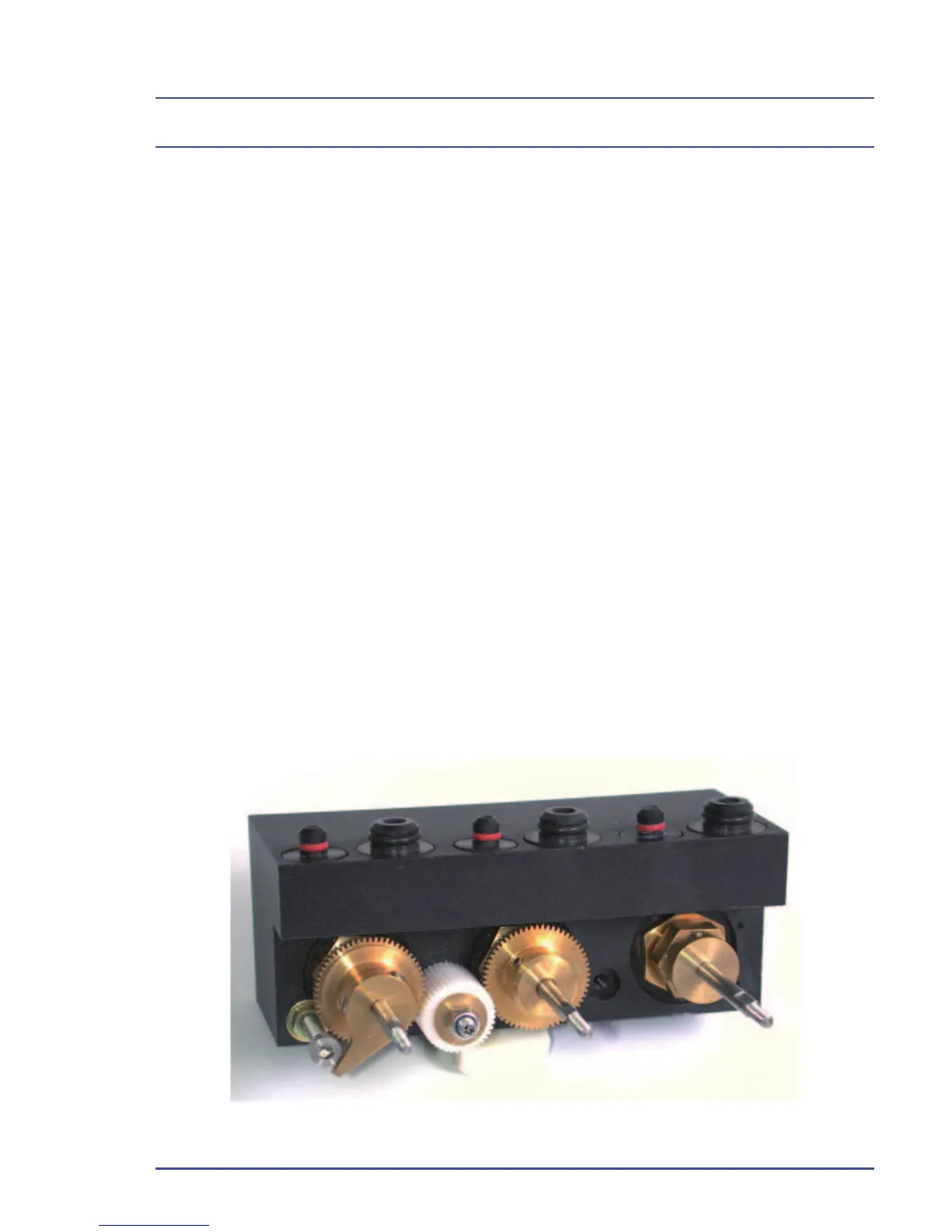

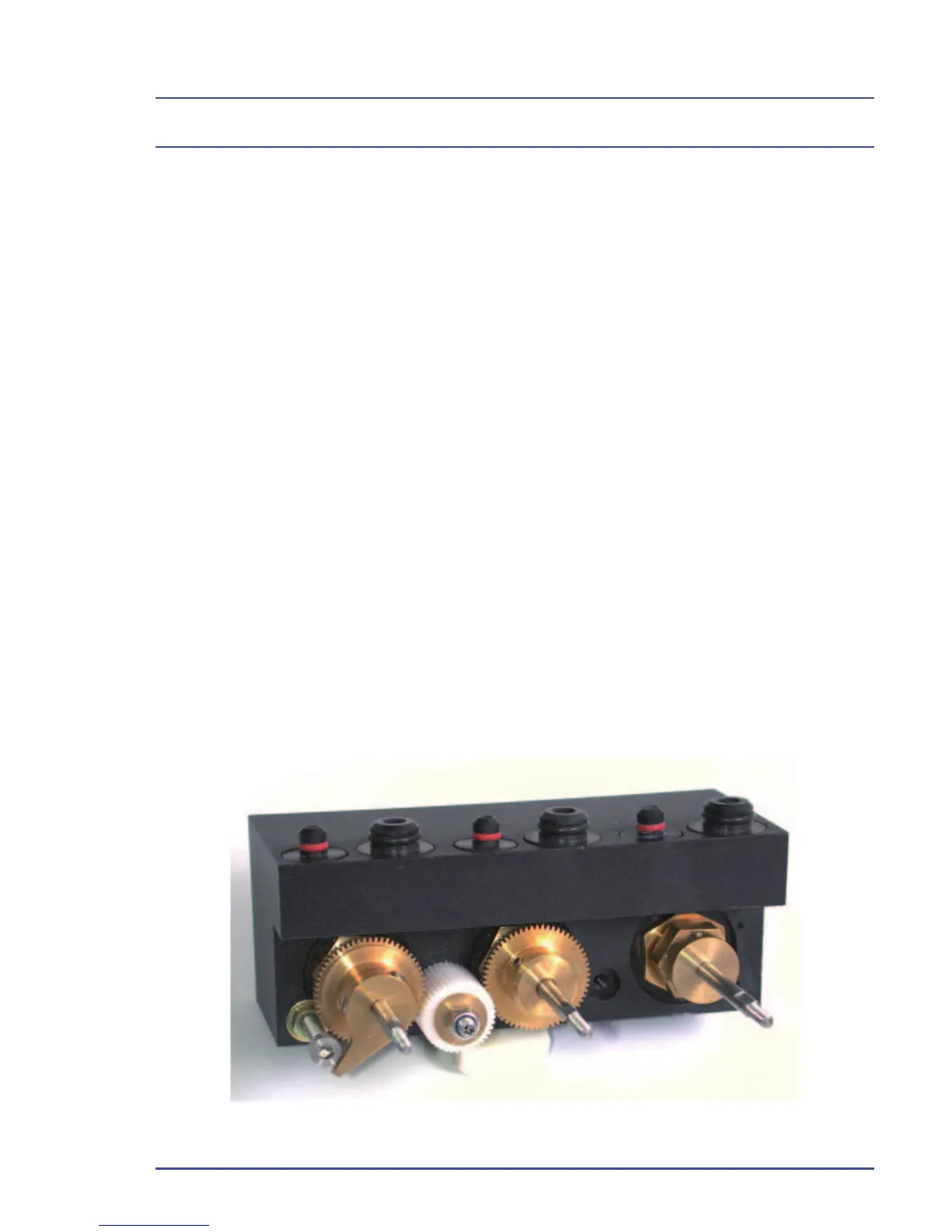

5.4 Nitrous Oxide and Air Flow Valve Leak Test

Setting Valve shut off stop.

Due to the precision construction of these valves it is essential that the control

needle and its seat are not over tightened. The nitrous oxide and air valves

(oxygen valve is never fully closed “Basal Flow”) are fi tted with stop collars to

prevent this (see Figure 61) fi rst check should be to ensure there is no leakage

through these valves.

To check these valves, fi rst remove the front cover (Section 5.1).

Figure 60 - Assembled Hypoxic Guard Unit

Detailed Repair Procedures

Loading...

Loading...