74

System Checks

15. Close all fl ow control valves.

16. Set a fl ow of 3 L/min on the O

2

and N

2

O fl ow control valves. Verify that the

O

2

analyzer reads between 47-53%.

17. Set a fl ow of 6 L/min on the O

2

and N

2

O fl ow control valves . Verify that

the O

2

analyzer reads between 47-53%.

18. Close the O

2

and N

2

O fl ow control valves.

19. Set a fl ow of 3 L/min on the O

2

and Air fl ow control valves. Verify that the

O

2

analyzer reads between 57-63%.

20. Set a fl ow of 6 L/min on the O

2

and Air fl ow control valves. Verify that the

O

2

analyzer reads between 57-63%.

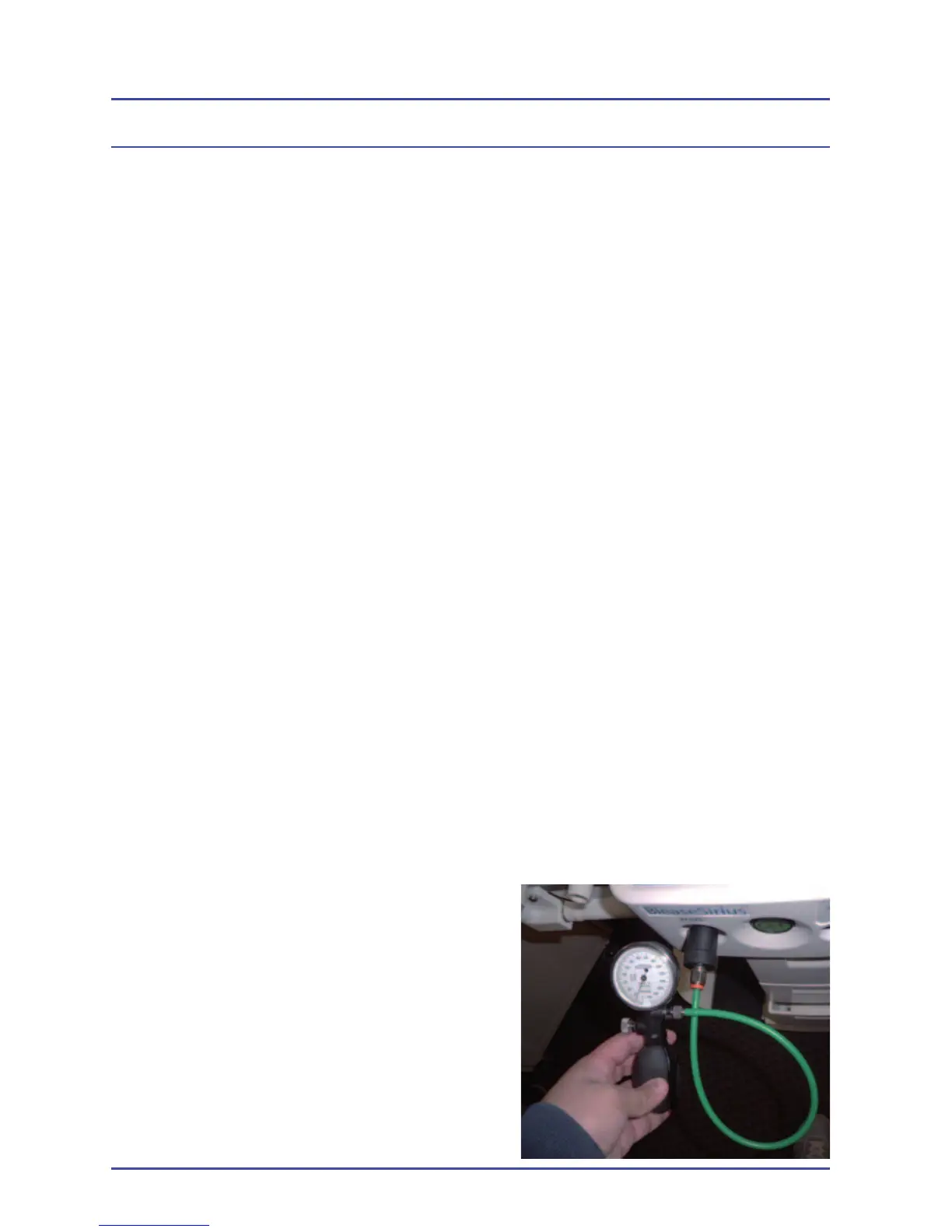

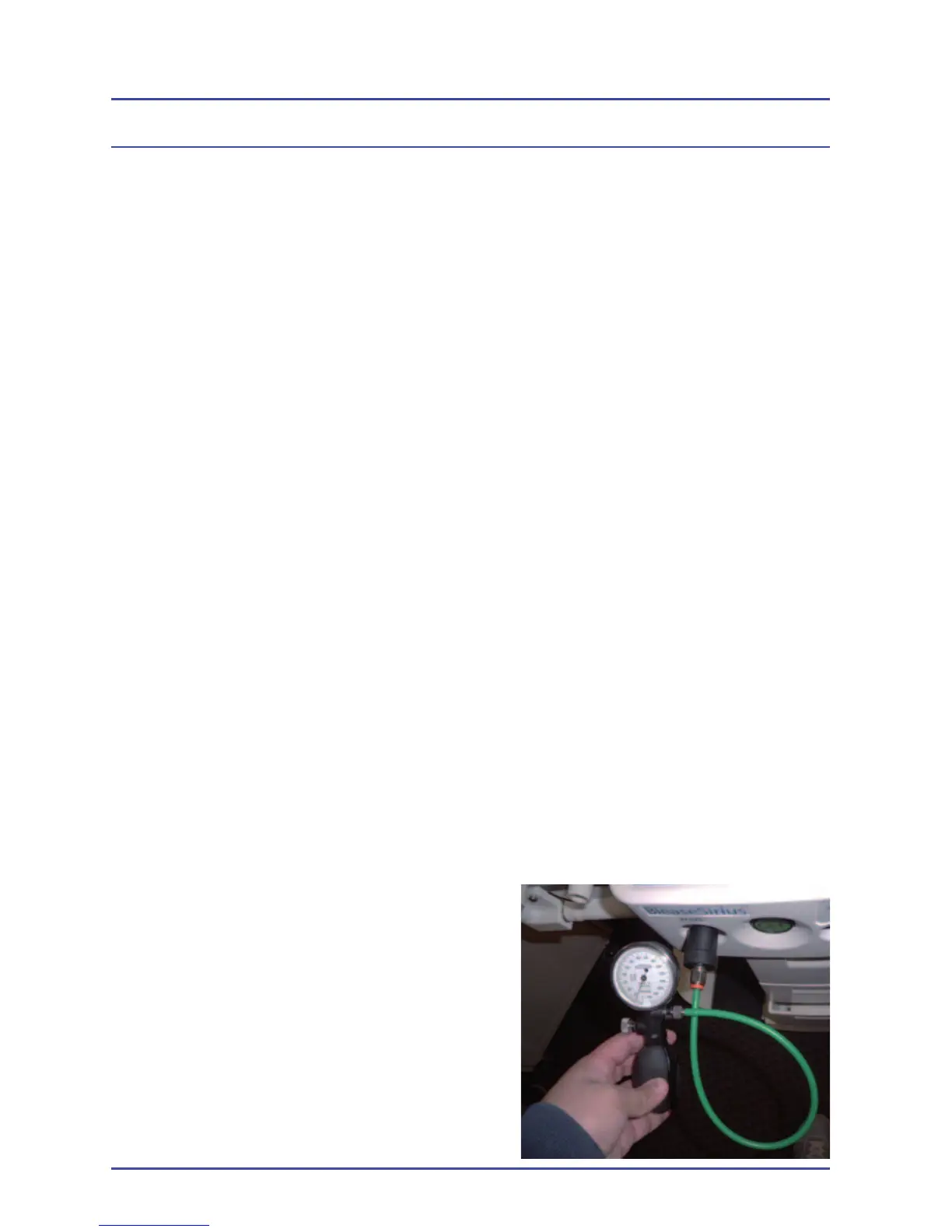

4.11 Backbar Tests

4.11.1 Pressure Build-up Test

1. Ensure that an O

2

supply is connected to the machine.

2. Ensure that the power switch is in the “OFF” position.

3. Ensure that all fl ow control valves are closed.

4. Connect a bulb and pressure gauge to the CGO taper.

If the machine is fi tted with an ACGO, ensure that the switch is set to

ACGO.

5. Turn the power switch to the “ON” position. Set of fl ow of 0.3 L/min on the

O

2

fl ow control valve.

6. Ensure that a pressure of 150 mmHg is reached within 7 seconds, then

turn the power switch to the “OFF” position.

Figure 23 - Pressure Build-up Test

Loading...

Loading...