137

Electrical and Ignition

Timing Adjustments

6

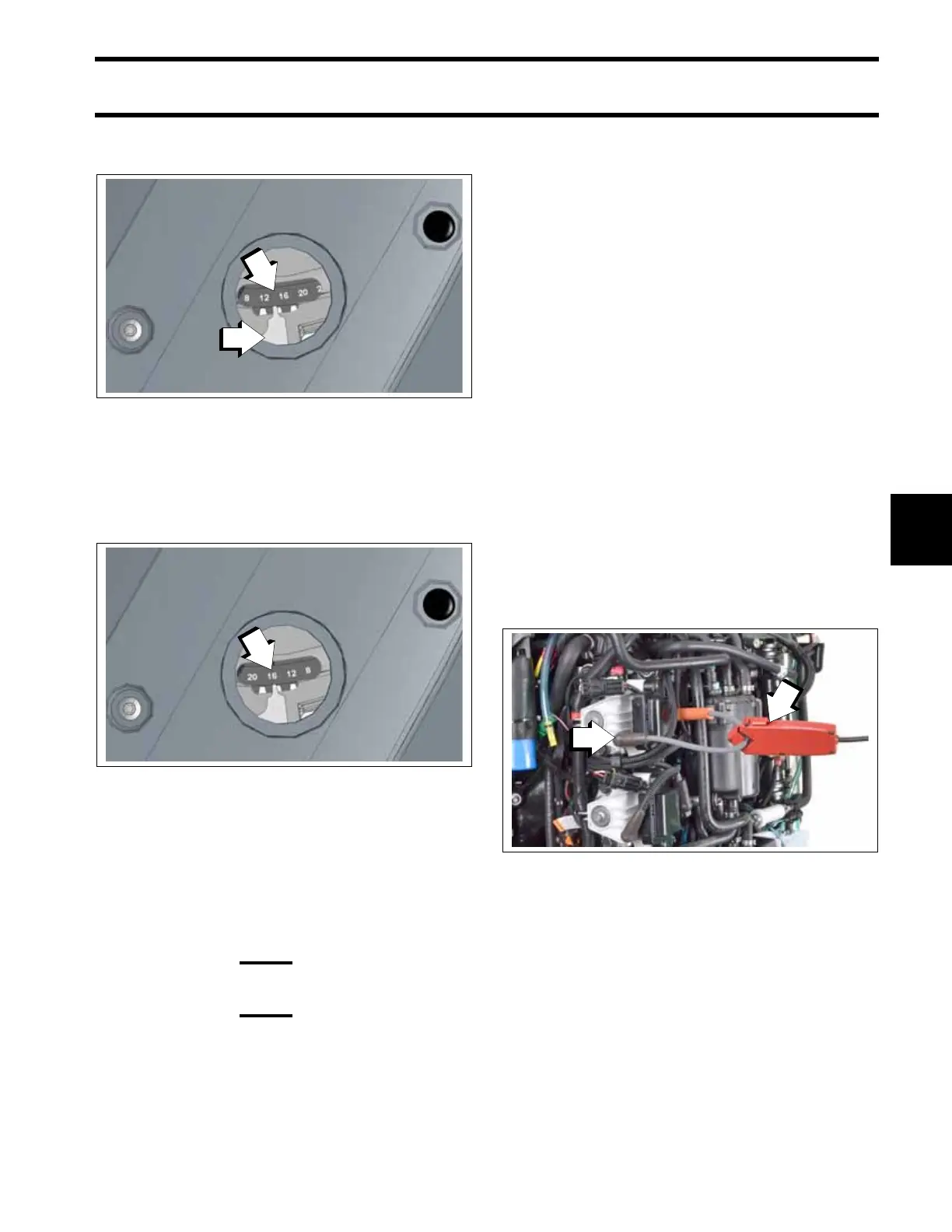

2. Record the degrees ATDC on the flywheel

directly across from the pointer.

3. Rotate the flywheel clockwise until the piston

contacts the tool.

4. Record the degrees BTDC on the flywheel

directly across from the pointer.

5. Add the number of degrees recorded in step 2

to the number of degrees recorded in step 4 to

obtain the degree Range.

Then divide the Range by 2 to obtain the

Result.

6. With the piston against the tool, adjust the

pointer to read the result from Step 5.

7. – Rotate the flywheel counterclockwise until

the piston contacts the tool. Record the

degrees ATDC on the flywheel.

– Rotate the flywheel clockwise until the pis-

ton contacts the tool. Record the degrees

BTDC on the flywheel.

– The timing pointer is correctly centered when

the piston contacts the tool at the Step 5 result,

at both the ATDC and BTDC positions.

8. Rotate the flywheel counterclockwise slightly

to release tool then remove it from spark plug

hole.

Install the spark plugs. Refer to Spark Plugs on

p. 22.

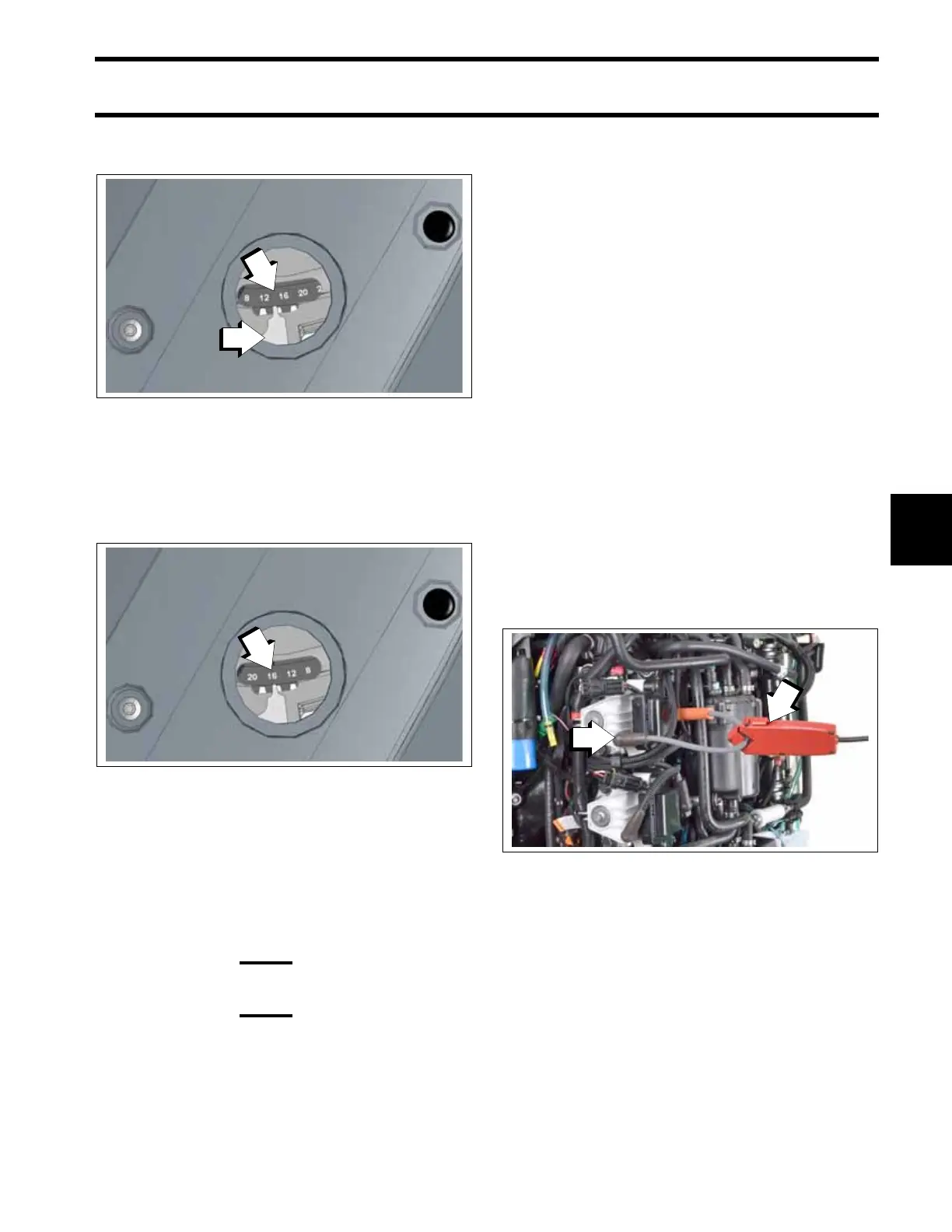

Install Timing Lead, P/N 587316, onto the #1 cyl-

inder coil and spark plug as shown. Connect the

timing light pick up to the timing lead.

IMPORTANT: Keep the timing light pick up a

minimum of 2 inches (51 mm) away from the igni-

tion coil during the timing verification procedure.

1. Timing pointer

2. Record the degrees on the flywheel

009365

1. Record the degrees on the flywheel

009366

Example:

14° ATDC

+16° BTDC

Range 30°

÷ 2

Result 15°

1. Timing Lead, P/N 587316

009364

2. Timing light pick up a minimum of 2 inches (51 mm) away from

the ignition coil

Loading...

Loading...