262

Powerhead

Powerhead Assembly

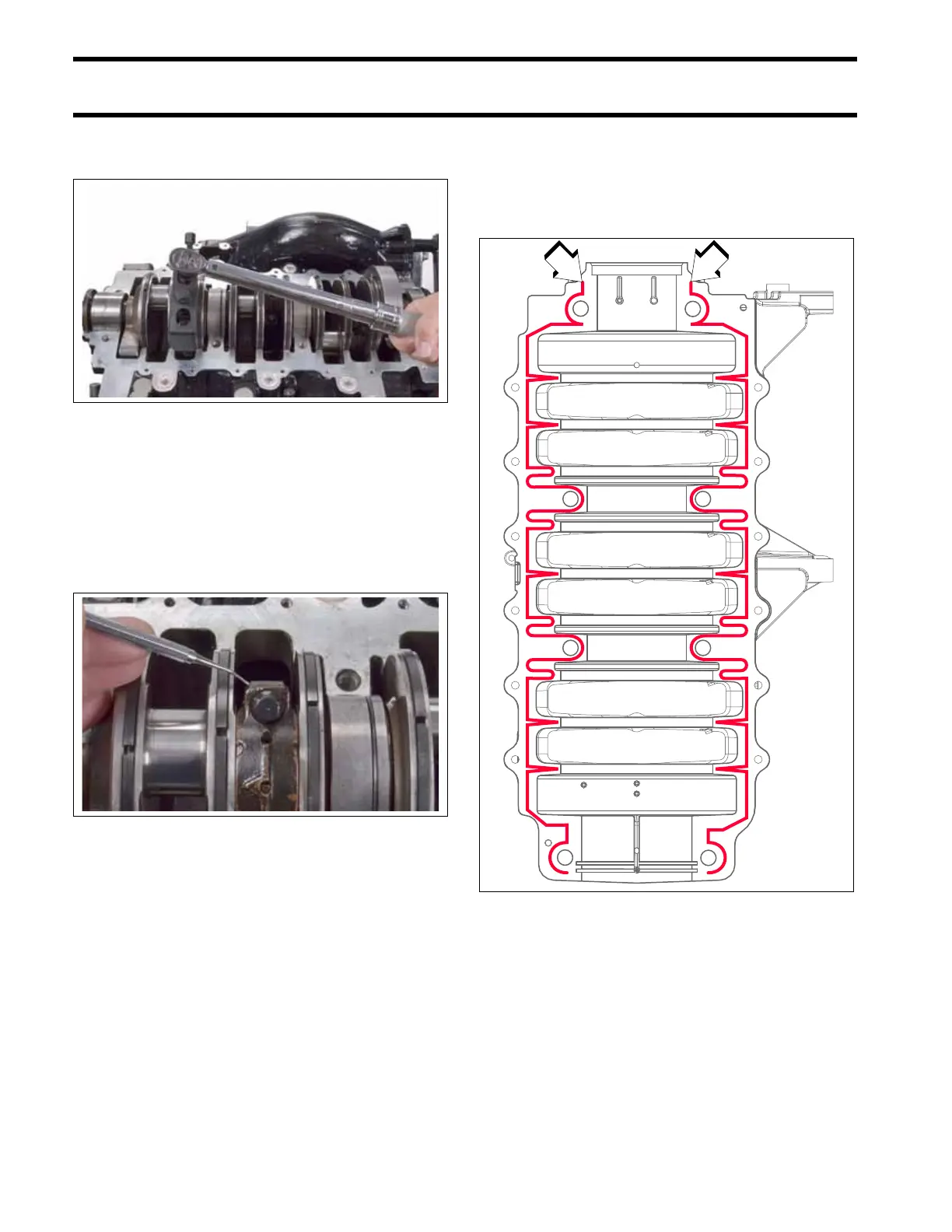

• Apply final torque of 60 to 65 ft. lbs. (81 to 88

N·m).

IMPORTANT: If a new screw is used, it must be

installed as above. Then, it must be removed, re-

lubricated, and installed again.

Loosen forcing screw and remove the frame.

Test at least three corners of the rod and cap joint

with a pick. Joint must be smooth with no step.

Crankcase Assembly

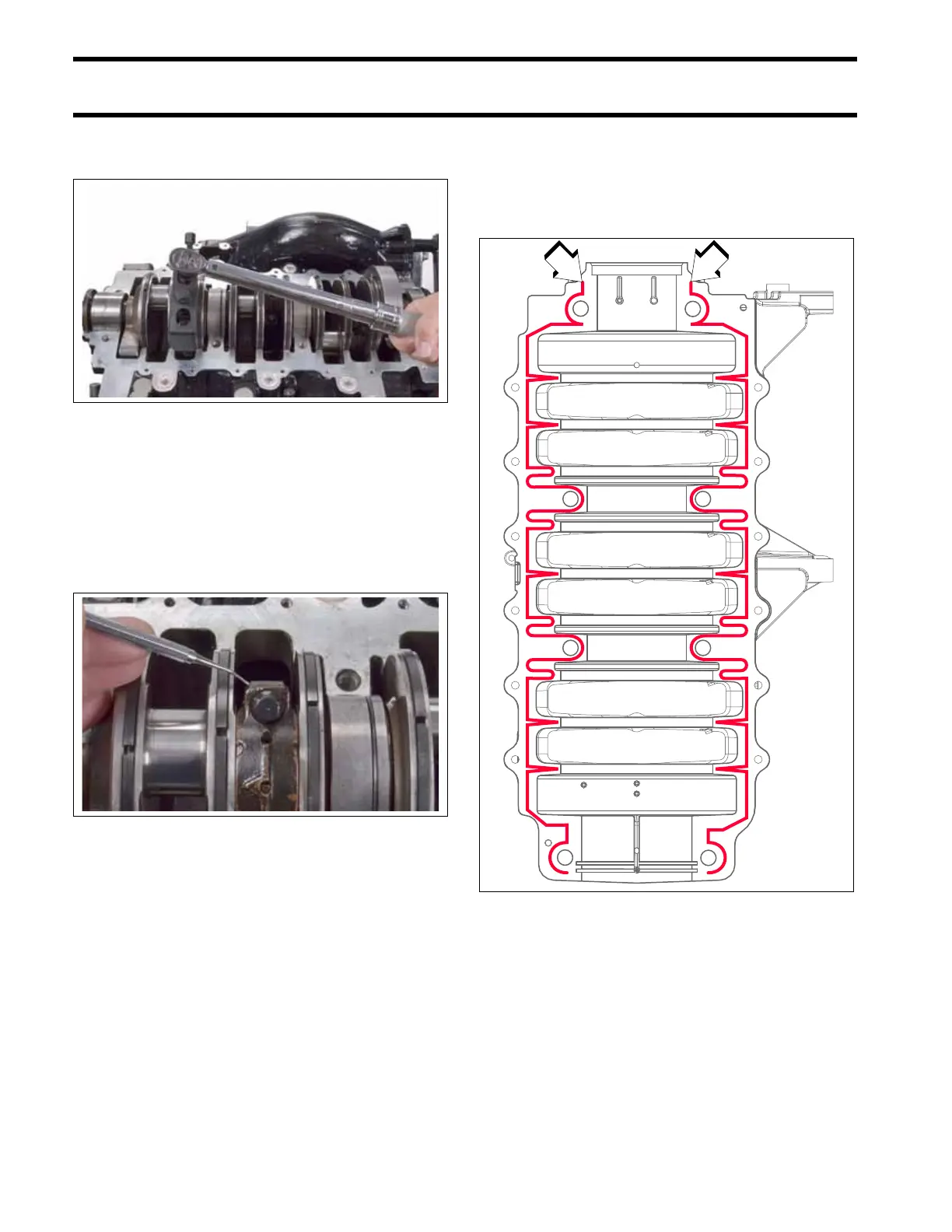

Thoroughly clean and degrease the mating

flanges of the crankcase and cylinder block with a

non-petroleum based solvent, such as isopropyl

alcohol or acetone, and let air dry.

IMPORTANT: DO NOT allow solvent to get on

internal components. Clean only the mating flang-

es.

A apply an even 1/8 inch (3 mm) bead of Three-

bond 1217H sealant, P/N 768611, to the crank-

case mating flange in the pattern shown below.

The sealant must not come within 1/4 in. (6.4 mm)

of bearings.

Lower the crankcase into place.

009718

009719

Threebond 1217H Sealant

009732

1. Even 1/8 inch (3 mm) bead

Loading...

Loading...