19

Routine Service

Maintenance

2

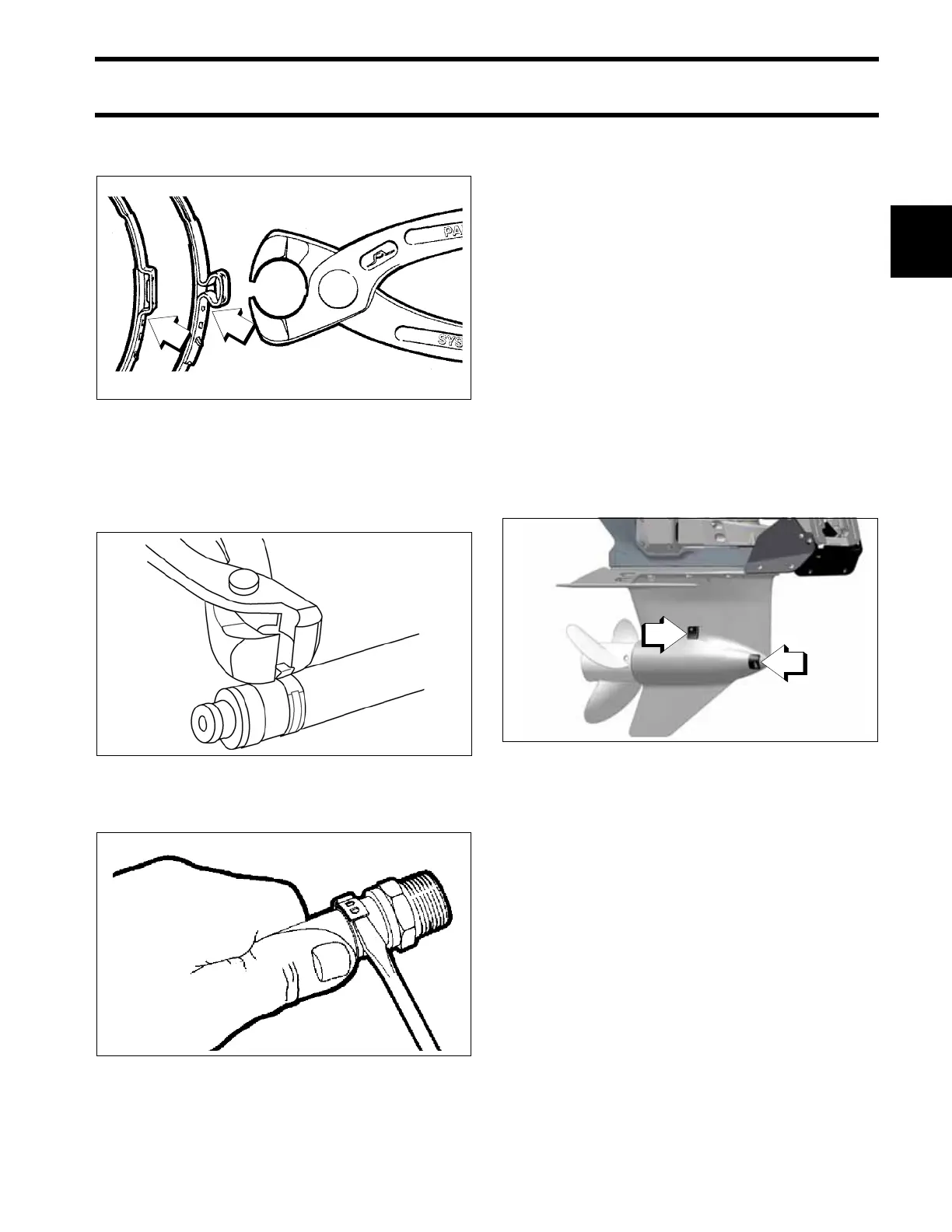

• Close clamp ear fully with Oetiker pincers (pli-

ers).

Clamp Removal

Method 1: Position Oetiker pincers across clamp

ear and cut clamp.

Method 2: Lift end of stepless clamp with screw-

driver.

Use Oetiker pincers (pliers) to grip clamp. Pull

clamp off of connection and discard.

Cooling System

Check the condition of cooling system compo-

nents regularly:

• water intake screens

• water pump

• all internal water passages

• thermostats

• all external water hoses and fittings

• vapor separator cooling passages and fittings

• EMM cooling passages and fittings

• overboard water pressure indicator.

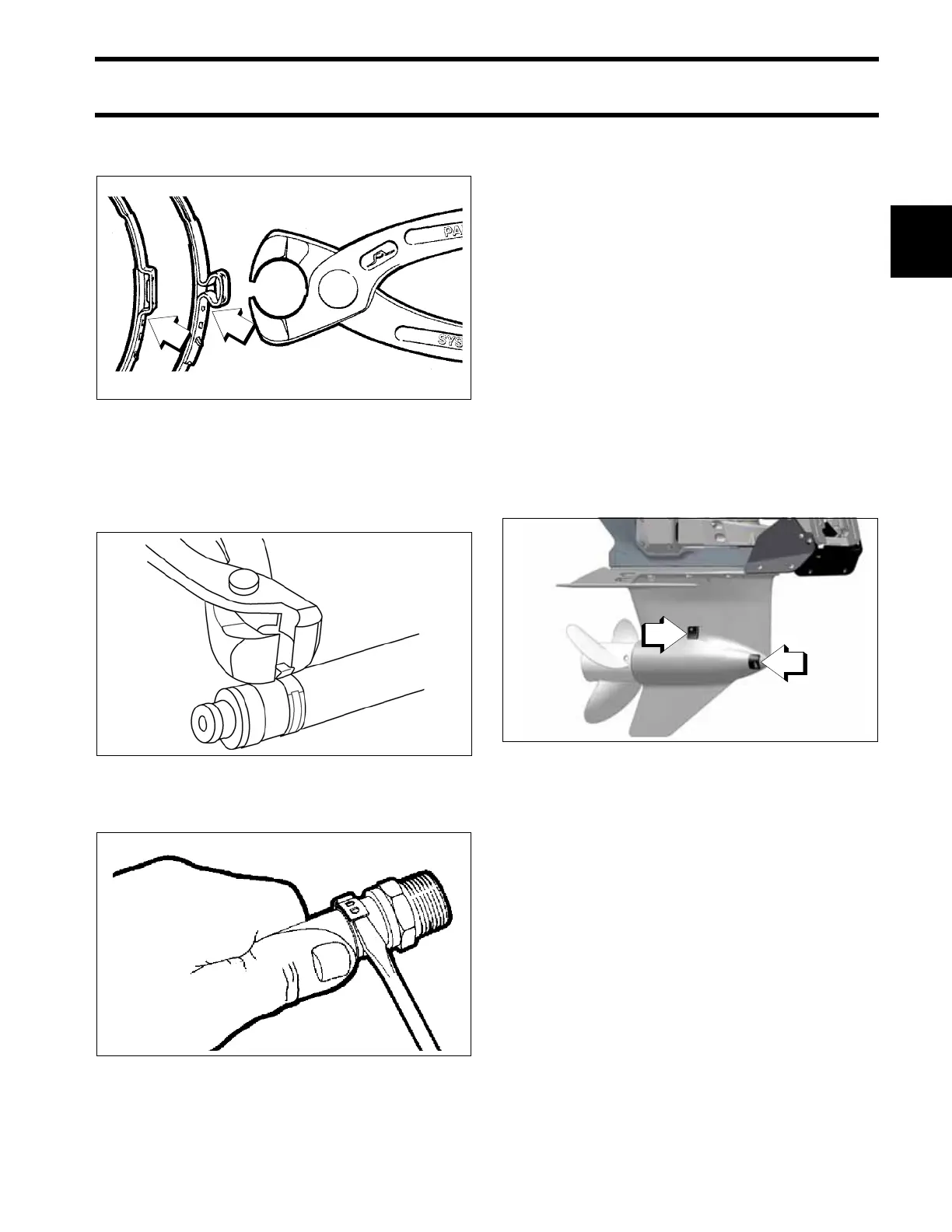

Water Intake Screens

Inspect condition of water intake screens. Clean

or replace as needed.

Confirm function of overboard water pressure indi-

cator.

Engine Flushing

Flush the outboard with fresh water following each

use in brackish, salt, or polluted water to minimize

the accumulation of scale and silt deposits in cool-

ing system passages.

The outboard can be flushed on the trailer or at

dockside; running or not running.

IMPORTANT: The outboard must be located in a

well ventilated area with appropriate ground drain-

age during the flushing procedures.

Keep water inlet pressure between 20 to 40 psi

(140 to 275 kPa).

1. Open clamp

2. Closed clamp

000092

000108

000090

1. Water intake screens

009041

Loading...

Loading...