333

Stern and Swivel

Trim & Tilt System Service

13

Non-DPS Models

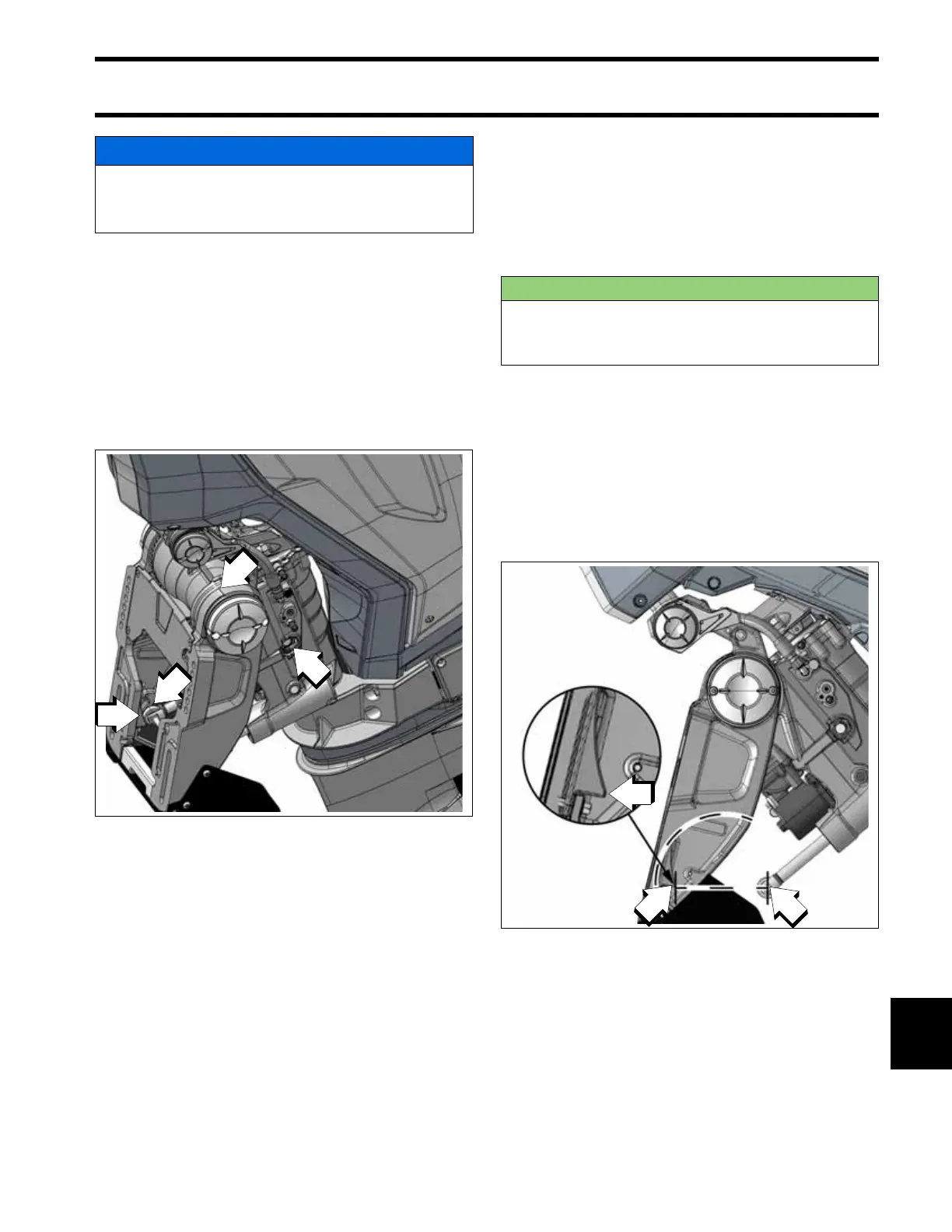

Trim the outboard up until the casting line on the

stern bracket aligns with the casting line on the tilt

shaft. In this position, the trim rollers should just

touching the trim ramps.

IMPORTANT: The outboard MUST be in this po-

sition to check fluid level. Any other position will re-

sult in under-filling or over-filling of the reservoir.

Check the fluid level. Fluid should be level to the

bottom of the fill plug threads.

Use a CLEAN funnel and hose to add Power

Trim/Tilt Fluid, P/N 767969, to bring the fluid level

to the bottom of the fill plug threads.

Do NOT over-fill. If the reservoir is over-full, allow

fluid to run into an appropriate container until the

fluid level is to the bottom of the fill plug threads.

Clean the reservoir cap. Verify that the o-ring seal

is installed in the cap. Lubricate the o-ring with

clean hydraulic fluid. Carefully install the cap. Do

NOT cross-thread the cap. Tighten it securely. Do

NOT over-tighten the cap.

Clean up spilled fluid with shop towels.

DPS Models

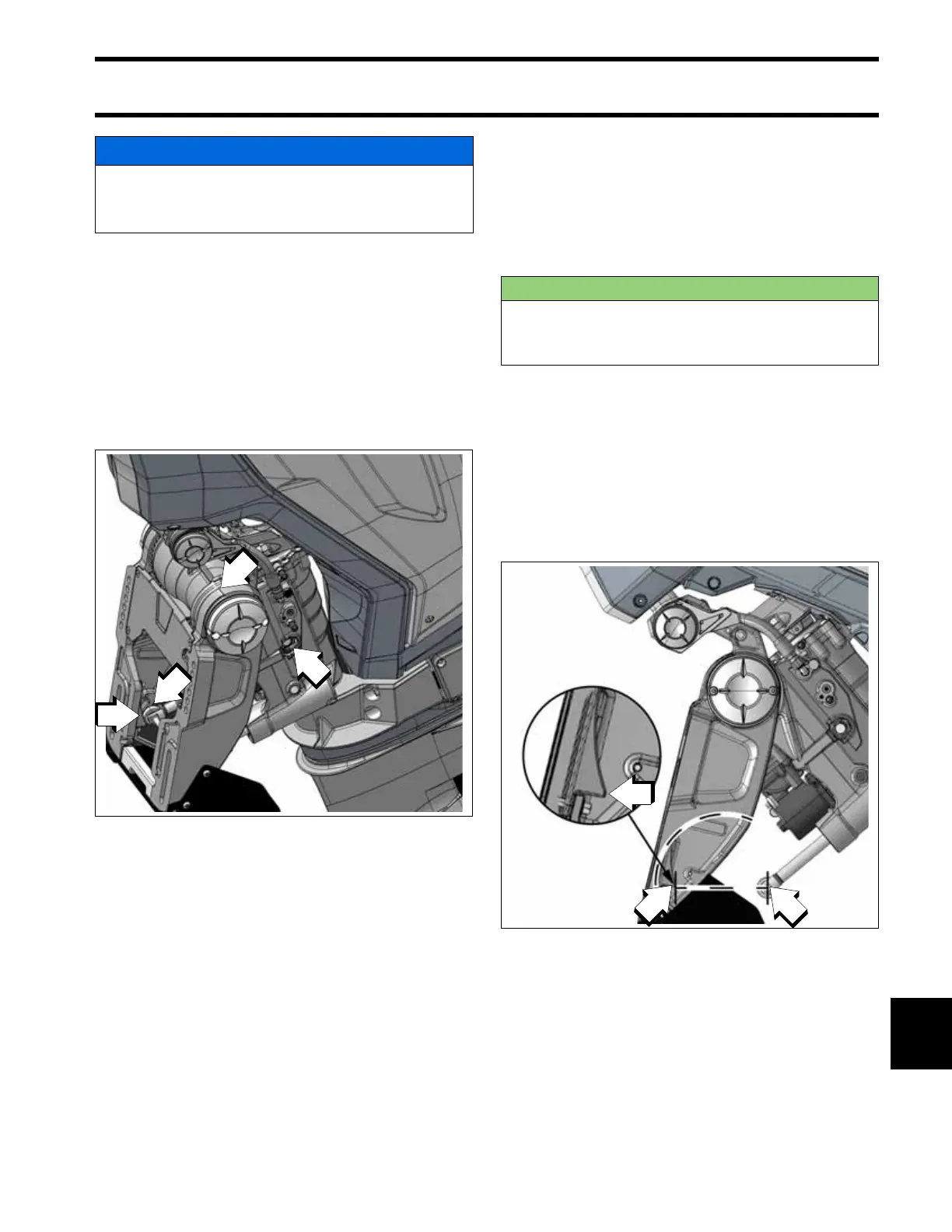

Trim the outboard UP until the center of the roller

shaft is 6–3/8 inches (162 mm) from the end of the

trim ramp.

IMPORTANT: The outboard MUST be in this po-

sition to check fluid level. Any other position will re-

sult in under-filling or over-filling of the reservoir.

Use a wax pencil (china marker) to make a refer-

ence mark across the tilt shaft and stern bracket.

This will be helpful in returning to the correct posi-

tion for checking fluid level. The trim and tilt MUST

NOTICE

Over-filling of the trim and tilt reservoir can

damage seals or o-rings resulting in trim fluid

leaks and loss of trim system operation.

Casting Line on Stern Bracket and Tilt Shaft

009483

1. Casting line on stern bracket and tilt shaft

2. Trim roller

3. Trim ramp

4. Reservoir cap

ENVIRONMENTAL NOTE

Dispose of spilled hydraulic fluid or contaminated

shop towels in an environmentally responsible

manner, or according to local regulations.

Center of Roller Shaft 6–3/8 in. (161.925 mm)

From End of Trim Ramp

009484

1. Center of roller shaft

2. End of trim ramp (cut-away view shown)

Loading...

Loading...