407

Gearcase

Shifter, Bearing and Seal Servicing

14

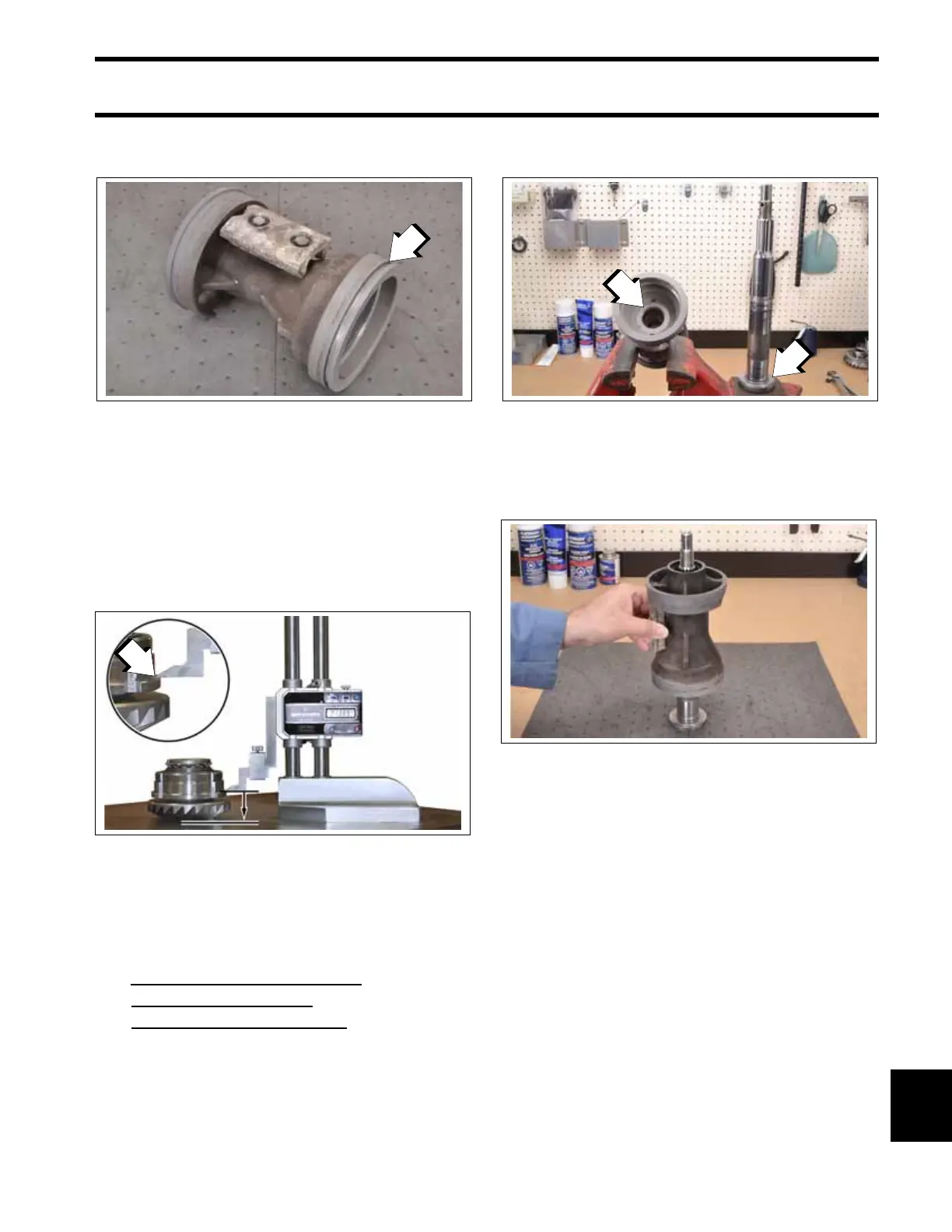

Remove any nicks or burrs on front of bearing

housing.

For seal and bearing service refer to Propeller

Shaft Bearing Housing Service on p. 387.

Assembly

Position the forward gear bearing housing assem-

bly on a flat, level surface. (Mirror or glass can be

used.) Use depth gauge to measure distance from

flange of housing to flat surface as shown.

Add the appropriate shims to create a dimension

of 0.140 in. (3.556 mm).

To determine thickness of shims; use the following

example:

1.389 in. reading on the gauge

+ 0.011 in. shims required

= 1.400 in. required dimension

Apply Needle Bearing grease to the thrust bear-

ing. Position bearing around shoulder on the pro-

peller shaft.

Apply Needle Bearing grease to the thrust washer.

Place washer in recess of bearing housing.

Coat bearing surfaces of propeller shaft with gear-

case lubricant. Slide the propeller housing onto

the propeller shaft.

IMPORTANT: Use caution when assembling the

propeller shaft in the bearing housing. Thrust bear-

ing must remain around shoulder on the propeller

shaft.

Apply gearcase lubricant to the threads of the for-

ward gear bearing housing.

1. O-ring groove

009568

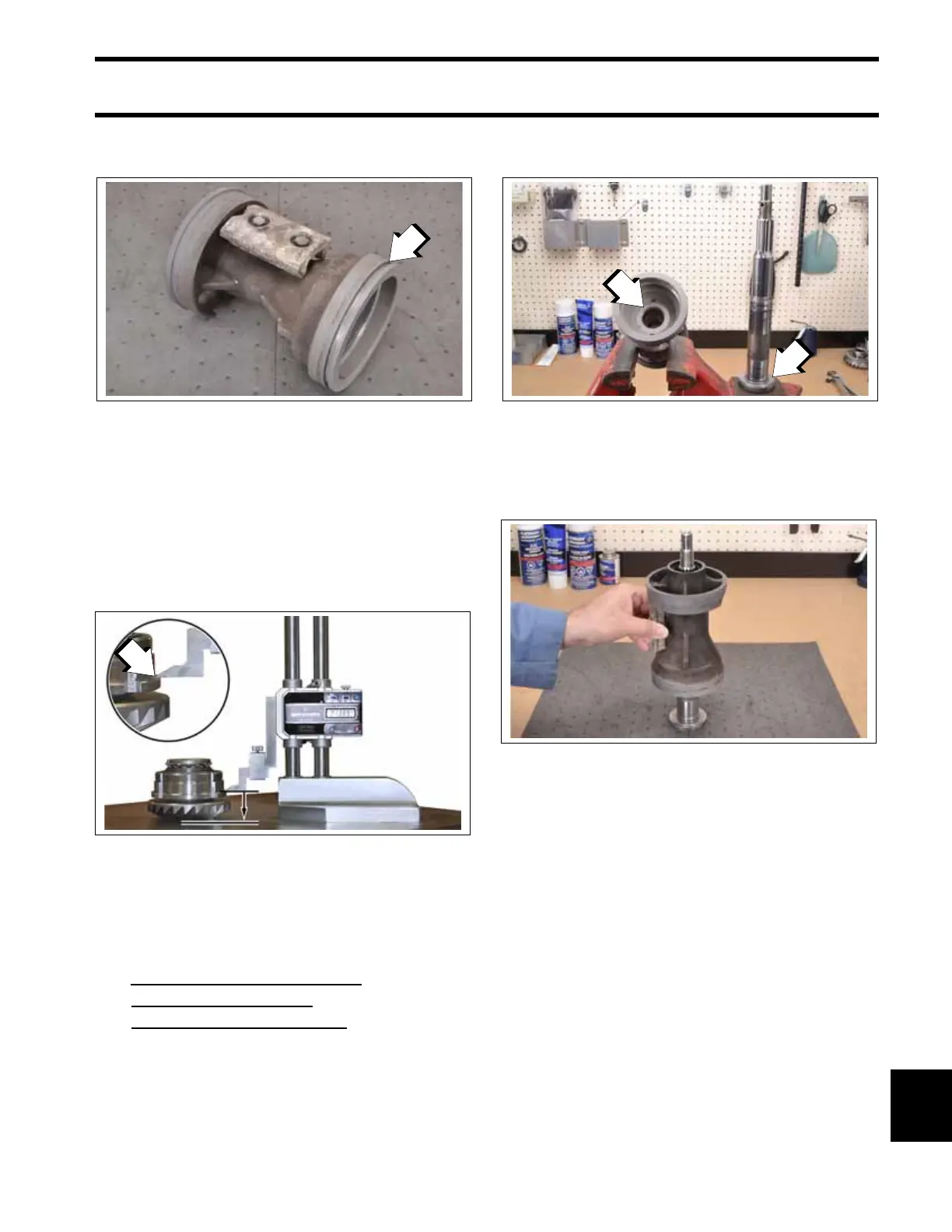

1. Flange

009564

1. Thrust bearing

2. Thrust washer

009565

009566

Loading...

Loading...