D 41 21

Direction marks

To ensure straight paving, a direction

mark must be present or established

(road edge, chalk lines or similar).

- Slide the operating panel to the de-

sired side and secure it.

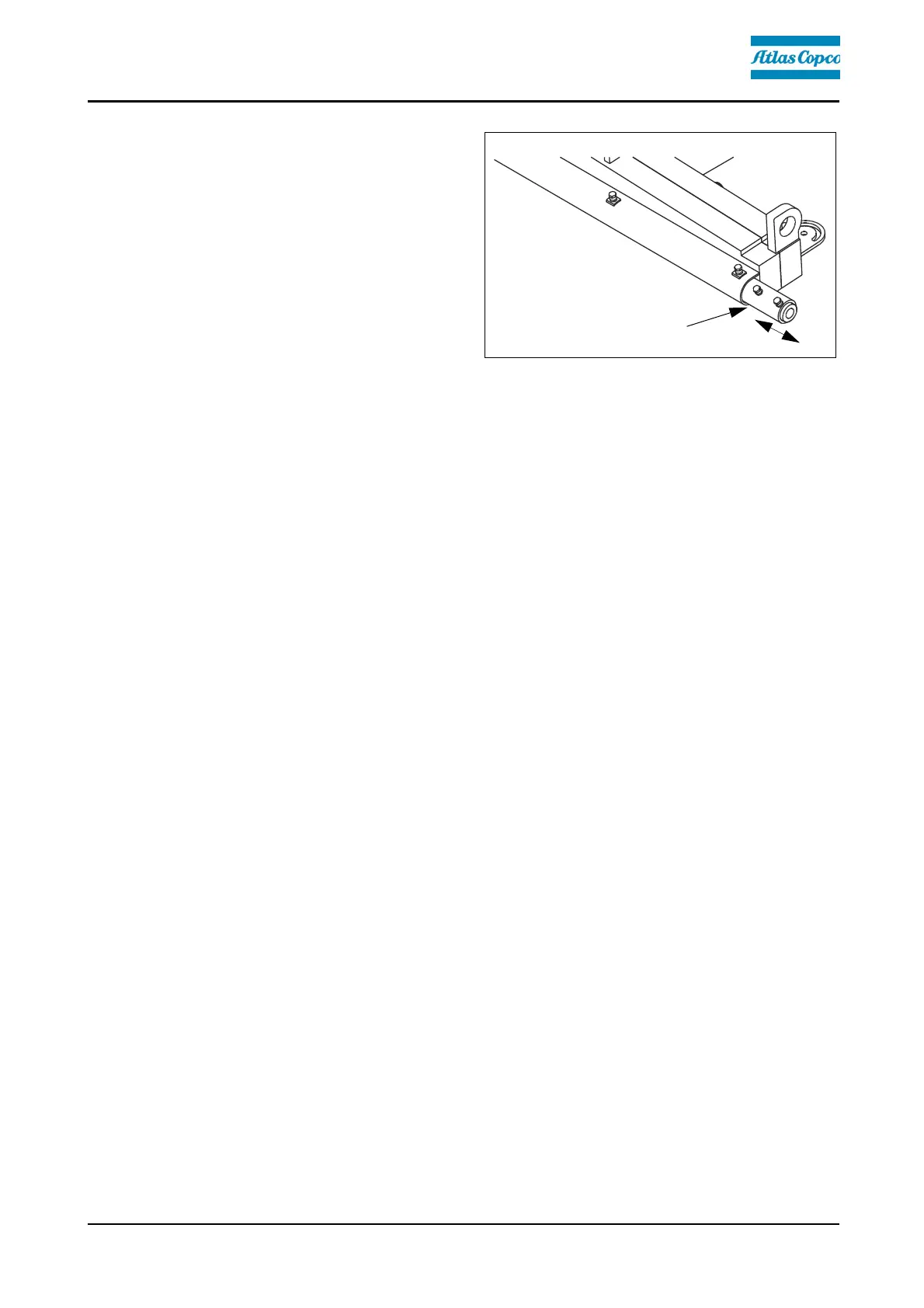

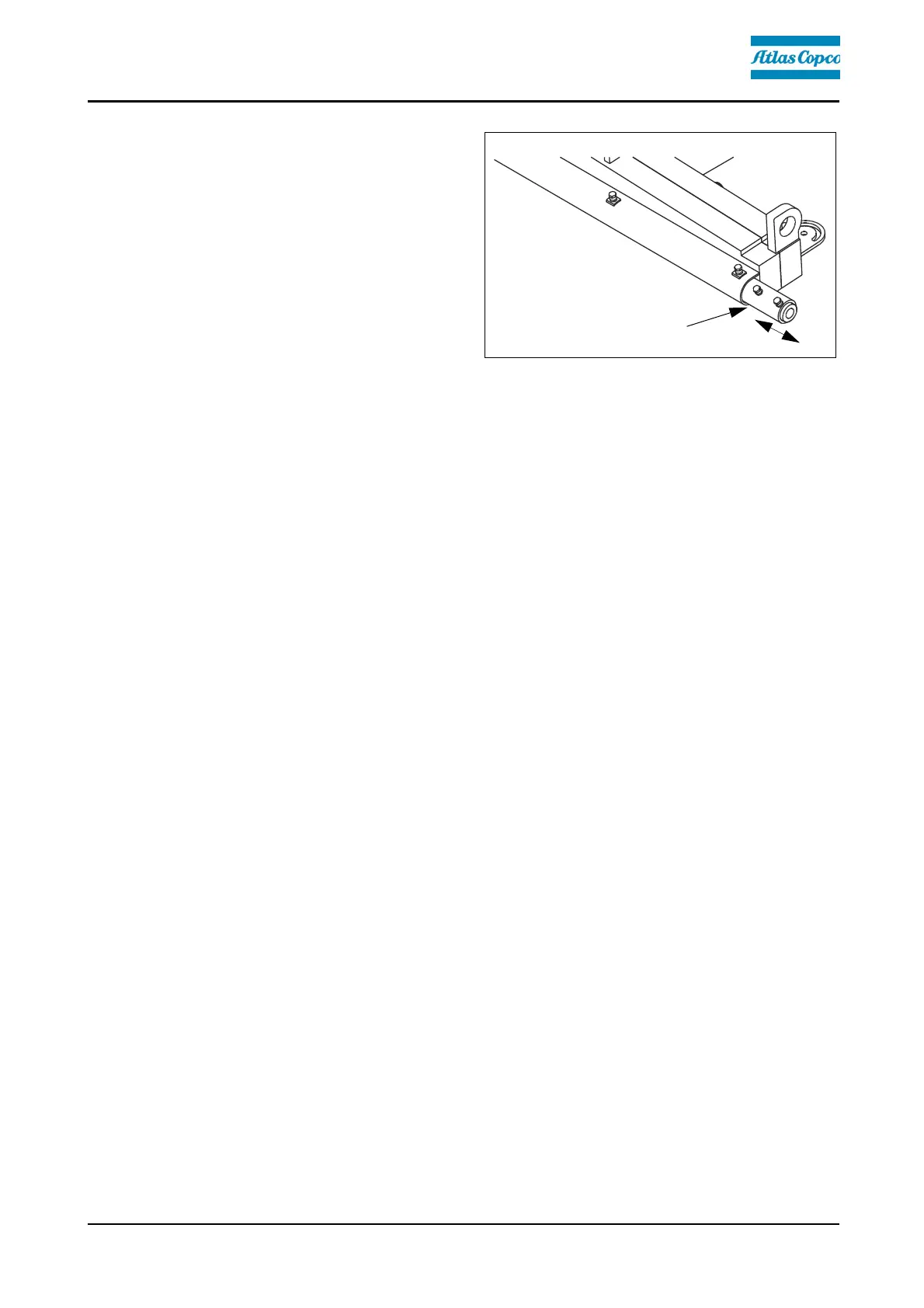

- Pull the direction indicator out of the

bumper (arrow) and adjust it accord-

ingly.

Loading...

Loading...