55

Receiver power supply

Receiver system

power supply

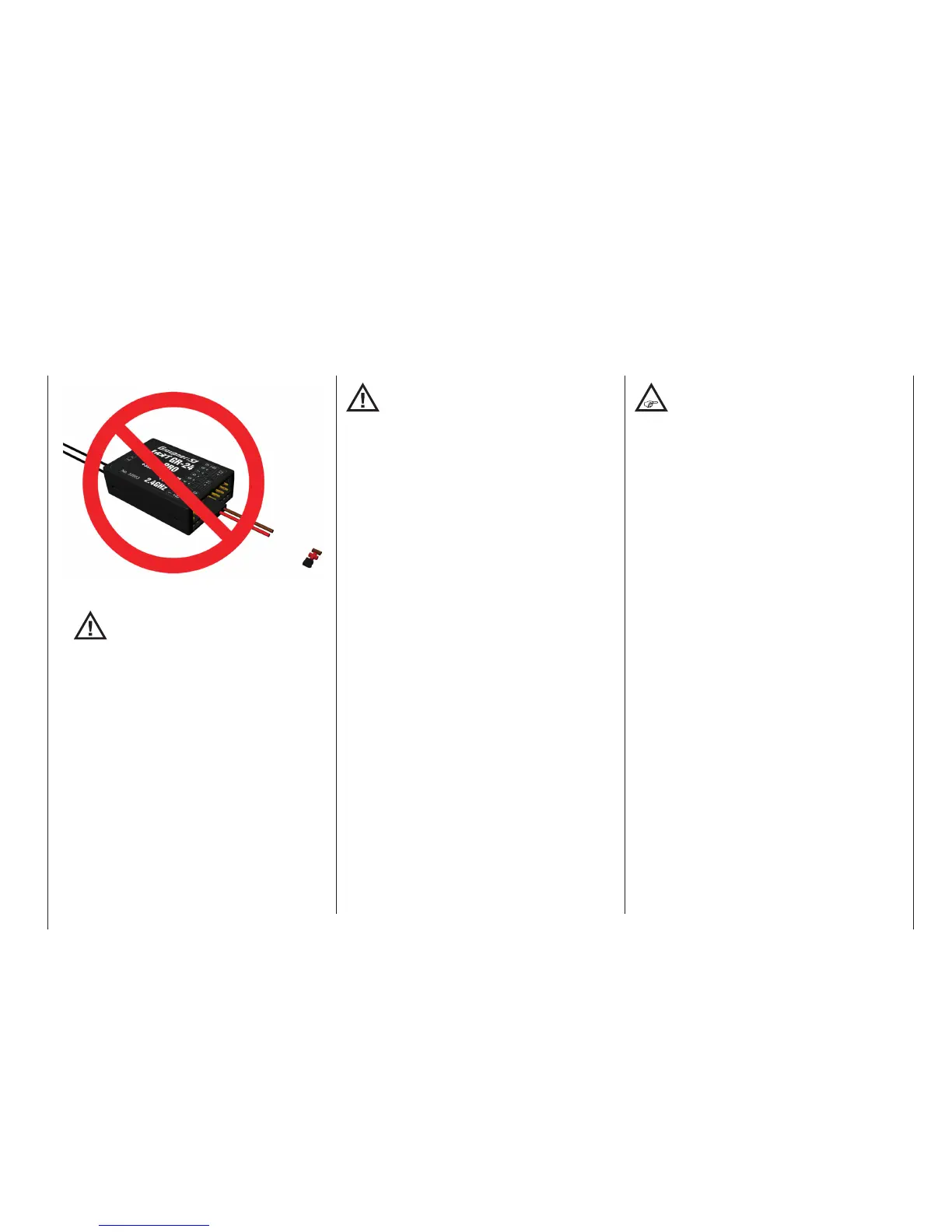

... but never so:

ATTENTION:

At the receiver, GR-32 “T” (telemetry) and

“S” (“Signal”) servos and other components

are connected horizontally only at the termi-

nals 13 to 16.

Under no circumstances may be connected across

the other terminals 1 to 12 components and espe

-

cially the receiver battery as shown demonstratively

in the figure above. The same applies to the termi-

nals 1 ... 6 of the receiver GR-12L. A plug in “cross”

over 2 to 3 terminals, immediately leads to a short

circuit of the receiver battery; the destruction of

possibly connected components and the immediate

loss of warranty claims.

The sequence in which servos are connected to the

receiver depends on the type of model. Follow the

con-

nection layouts provided for this on pages 65 and 69.

Also observe the safety notices provided on pages 4 …

10.

In order to prevent uncontrolled movements

of servos connected to the receiver during

startup

always rst switch on the transmitter

and then the receiver

and when finished with operation

rst switch off the receiver

and then the transmitter.

When programming the transmitter, be sure that elec-

tric motors cannot start running without control or that

a combustion motor equipped with automatic starting

cannot start up unintentionally. To be safe, disconnect

the receiver's drive battery or, in the case of a com-

bustion motor, disconnect the fuel supply.

Among other aspects, the safe operation of a

model depends on a reliable power supply. In

the event that, despite smooth operating rods,

fully charged battery, battery leads with adequate

cross-section, minimum contact resistances at con-

nectors, etc., the transmitter indicates repeated re-

ceiver voltage collapses or is receiver voltage is

generally too low; please give attention to the follow-

ing notices:

Give primary attention to fully charged batteries when

model operation is to be started. Be sure that the

contact surfaces of connectors and switches really

are low resistance. If necessary, measure the voltage

drop across installed switch cables when they are

under load because even new heavy-duty switches

can cause a voltage drop of up to 0.2 V. This value

can increase in contacts by factors as a consequence

of aging and oxidation. The constant vibrations and

jarring also takes its toll on contacts to produce a

creeping increase of contact resistance.

Servos present another possible problem source.

Even rather small servos like a Graupner/JR DS-281

can draw up to 0.75 A of current when it is blocks un-

der load. Just four of these servos in a “foam” model

can therefore load down the on-board power supply

by as much as 3 A …

A further factor is that 2.4 GHz receivers generally

pass control signals to servos at a higher rate than

with comparable receivers used in earlier frequency

ranges. This equates to shorter “off” periods, which

also has an effect on the power consumption of the

receiving system. The current drain of many of today’s

digital servos is also higher, reflected by their greatly

improved ability to hold the prescribed position be-

tween control signals.Therefore you should choose a

power supply which will not break down under greater

loads but rather always deliver sufficient voltage. To

“calculate” necessary battery capacity you should

always figure on at least 350 mAh for every analog

Loading...

Loading...