81

Motor Measurement (Motor Analysis-Equipped Model)

Connection examples of motor analysis

In these examples, a torque meter and a tachometer are being connected with Ch. A to Ch. D.

You can connect them to Ch. E through Ch. H as well.

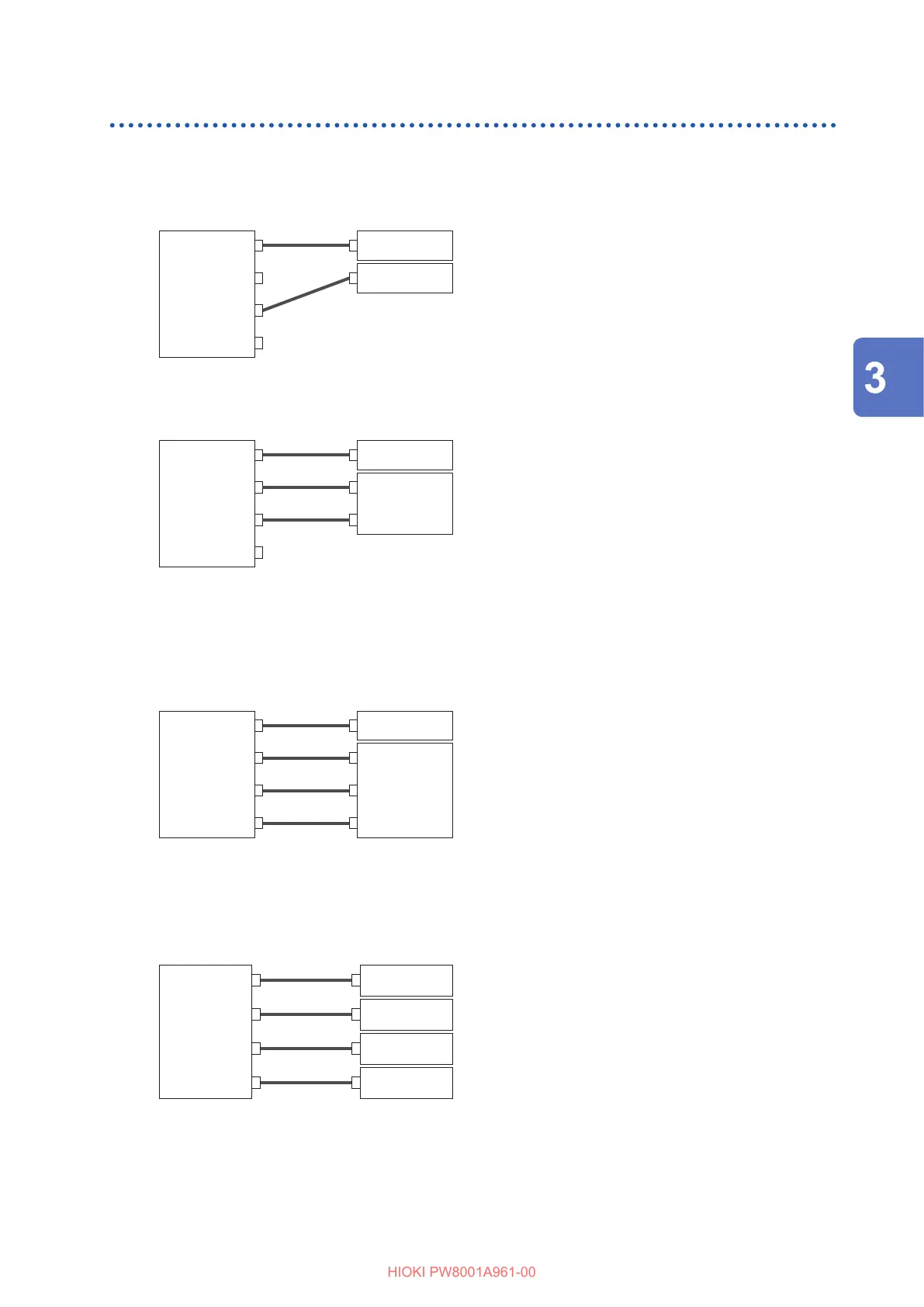

Example 1: Motor power measurement (settings of motor analysis mode pattern 5)

Ch. A or Ch. E

Ch. B or Ch. F

Ch. C or Ch. G

Ch. D or Ch. H

Torque output

RPM output

Input the torque signal to Ch. A and the RPM signal

to Ch. C. Then measure the motor power and motor

eciency.

The torque signal can use an analog DC signal or pulse-

based frequency input.

The RPM signal must be an analog DC signal.

The torque signal and RPM signal can be inputted from

dierent sensors.

Example 2: Motor power measurement with forward/reverse detection

(setting of motor analysis mode pattern 3)

Torque output

Ch. A or Ch. E

Ch. B or Ch. F

Ch. C or Ch. G

Ch. D or Ch. H

A-phase

pulse output

B-phase

pulse output

Torque output

Input the torque signal to Ch. A, the A-phase pulse signal

to Ch. B, and the B-phase pulse signal to Ch. C. Then

measure the motor power and motor eciency while

viewing the direction of the motor’s rotation based on

the phase dierence between the A-phase pulse and the

B-phase pulse.

The torque signal can use an analog DC signal or pulse-

based frequency input.

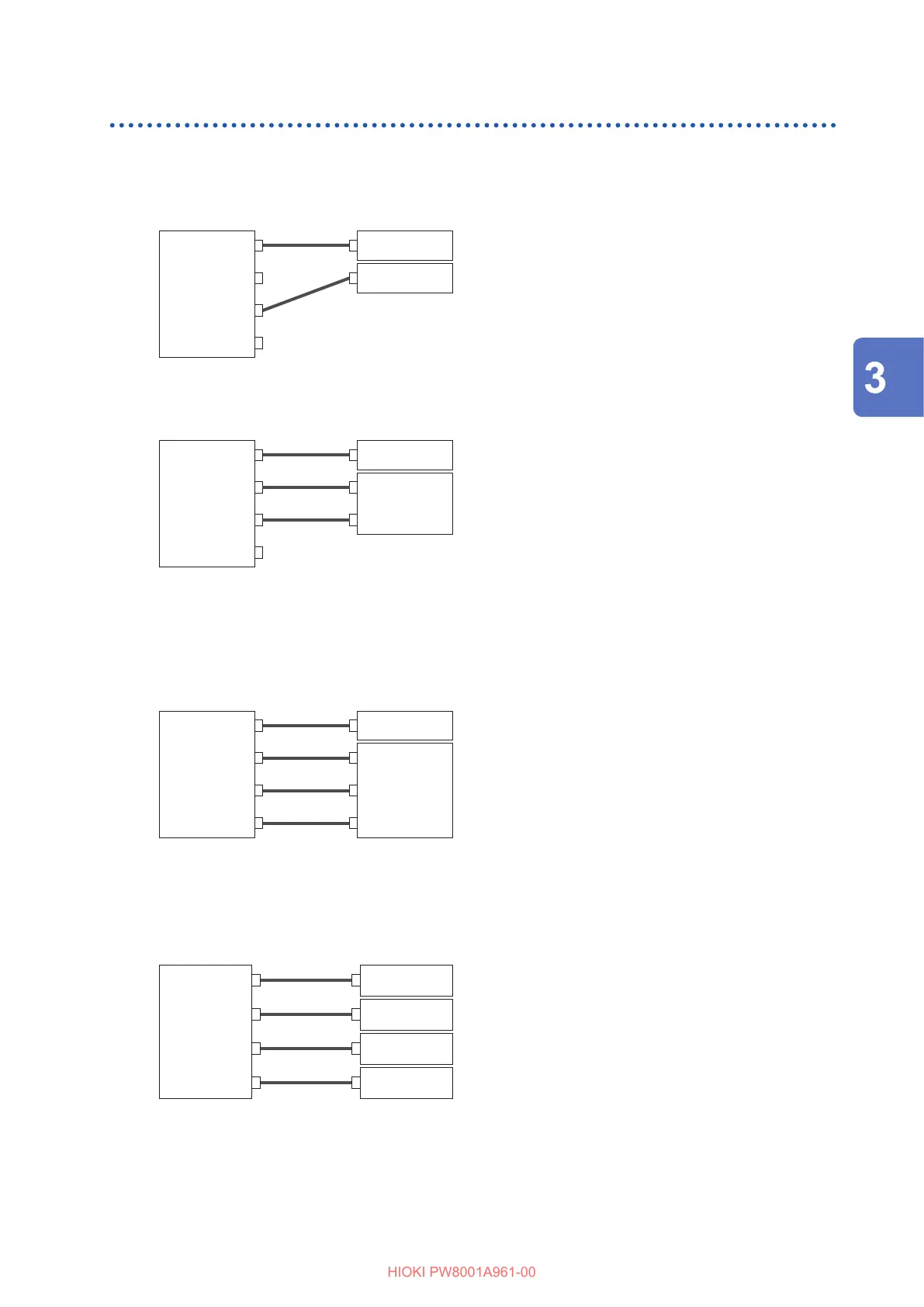

Example 3: Motor power measurement with electrical angle measurement

(settings of motor analysis mode pattern 2)

Ch. A or Ch. E

Ch. B or Ch. F

Ch. C or Ch. G

Ch. D or Ch. H

Torque output

A-phase

pulse output

B-phase

pulse output

Z-phase

pulse output

Input the torque signal to Ch. A, the A-phase pulse signal

to Ch. B, the B-phase pulse signal to Ch. C, and the

Z-phase pulse (origin) signal to Ch. D. Then measure the

motor power and motor eciency while measuring the

electrical angle.

By setting the synchronization source to Zph., you can

synchronize measurement to the mechanical angle

instead of the electrical angle.

The torque signal can use an analog DC signal or pulse-

based frequency input.

If you do not need to detect the direction of the motor’s

rotation, it is not necessary to input the B-phase pulse to

Ch. C, and you can select pattern 4 instead.

When using Zph. as the synchronization source, you

need to input not only the Z-phase pulse to Ch. D, but

also the A-phase pulse to Ch. B.

Example 4: Motor power measurement (settings of motor analysis mode pattern 1)

Ch. A or Ch. E

Ch. B or Ch. F

Ch. C or Ch. G

Ch. D or Ch. H

Torque output

RPM output

Torque output

RPM output

Input the torque signal and the RPM signal to Ch. A and

Ch. B to measure the motor power and motor eciency

of the rst system. Input the torque signal and the RPM

signal to Ch. C and Ch. D to measure the motor power

and motor eciency of the second system.

The torque signal can use an analog DC signal or pulse-

based frequency input.

Only pulse-based RPM signal can be input.

Conguring connected motor input settings and displaying measured values

For details about the display of measured values and the settings for inputting signals, see “3.6

Motor Measurement (Motor Analysis-Equipped Model)” (p. 78).

Displaying Power Numerically

Loading...

Loading...