43

Setting Wiring Mode and Conguring Current Sensor Settings

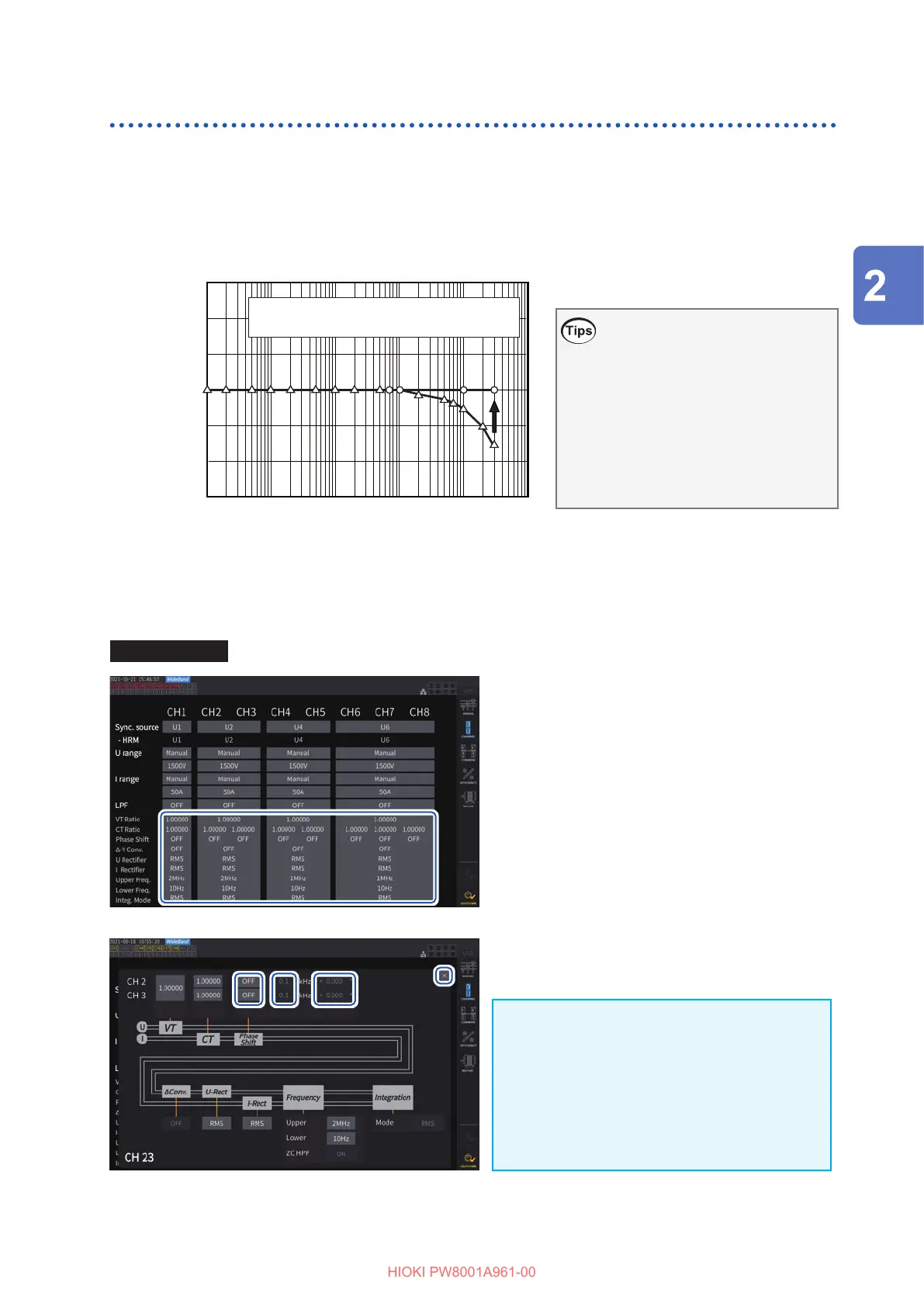

Correcting phase errors for current sensors

Current sensors generally exhibit a tendency for phase error to increase gradually in the high-

frequency region of their frequency band. By using sensor-specic phase characteristics

information to correct the measured values, it is possible to reduce the error component in power

measurement made in a high-frequency region.

Conceptual diagram

Frequency (Hz)

Phase (

°

)

1 M10

−

30

−

20

−

10

0

10

20

30

100 1 k 10 k 100 k

○: Phase characteristics after correction

Δ

: Phase characteristics before correction

Phase correction for current

sensors with auto-recognition

function

When using a current sensor with the

auto-recognition function, the phase of the

current sensor is automatically corrected.

If you wish to set any phase correction

values, follow the steps listed in the

following “How to enter phase correction

values” section.

How to enter phase correction values

For current sensors without the auto-recognition function, it is recommended to perform phase

correction for the current sensor before measurement.

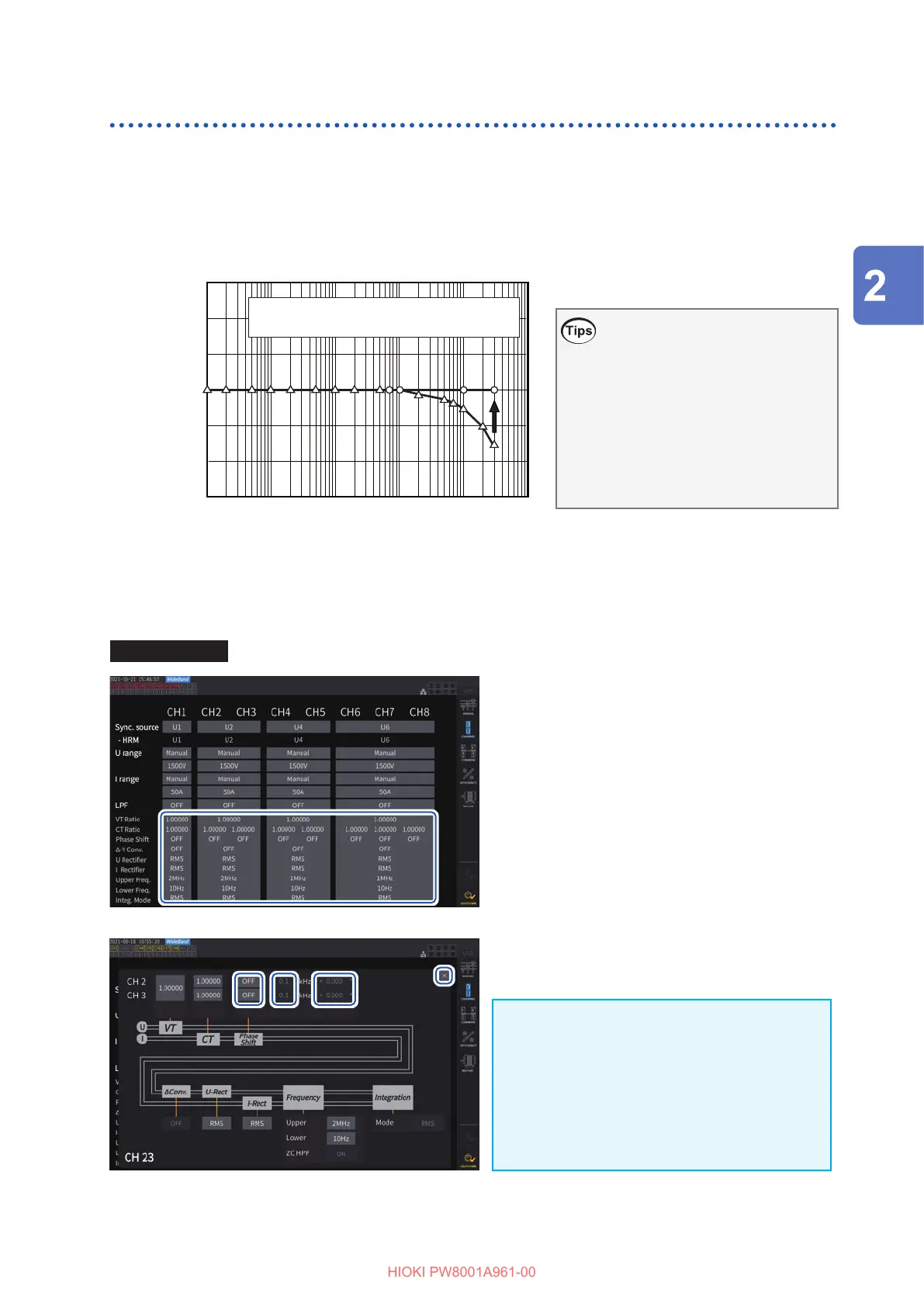

Display screen [INPUT] > [CHANNEL]

11

1

Tap the detailed display area for the

channel to be congured.

2

Tap the [Phase Shift] area box and

select [On].

When using a current sensor equipped with the

auto-recognition function, [Auto] is displayed

as an alternatives. When [Auto] is selected,

the correction values are entered automatically.

3

Tap the frequency box, then enter the

frequency with the numeric keypad.

4

Tap the phase dierence box, then

enter the phase dierence with the

numeric keypad.

5

Tap [

×

] to close the setting window.

IMPORTANT

• Enter the phase correction value accurately.

Invalid settings can cause the correction

process to increase measurement error.

• Operation outside the frequency range within

which the current sensor’s phase accuracy is

specied is not dened.

22 33 44

55

Preparing for Measurement

Loading...

Loading...