83

Motor Measurement (Motor Analysis-Equipped Model)

Zero adjustment of motor input

In the following circumstances, perform zero adjustment to eliminate errors caused by input signal

osets:

• When an analog DC voltage is inputted to Ch. A, Ch. C, Ch. E, and Ch. G

• When frequency-based torque signal is input

In the following circumstances, perform zero adjustment while the instrument is receiving zero input

for the torque and RPM signals:

• When a torque value is displayed even though no torque signal is generated

• When an RPM value is displayed even though no rotation signal is generated

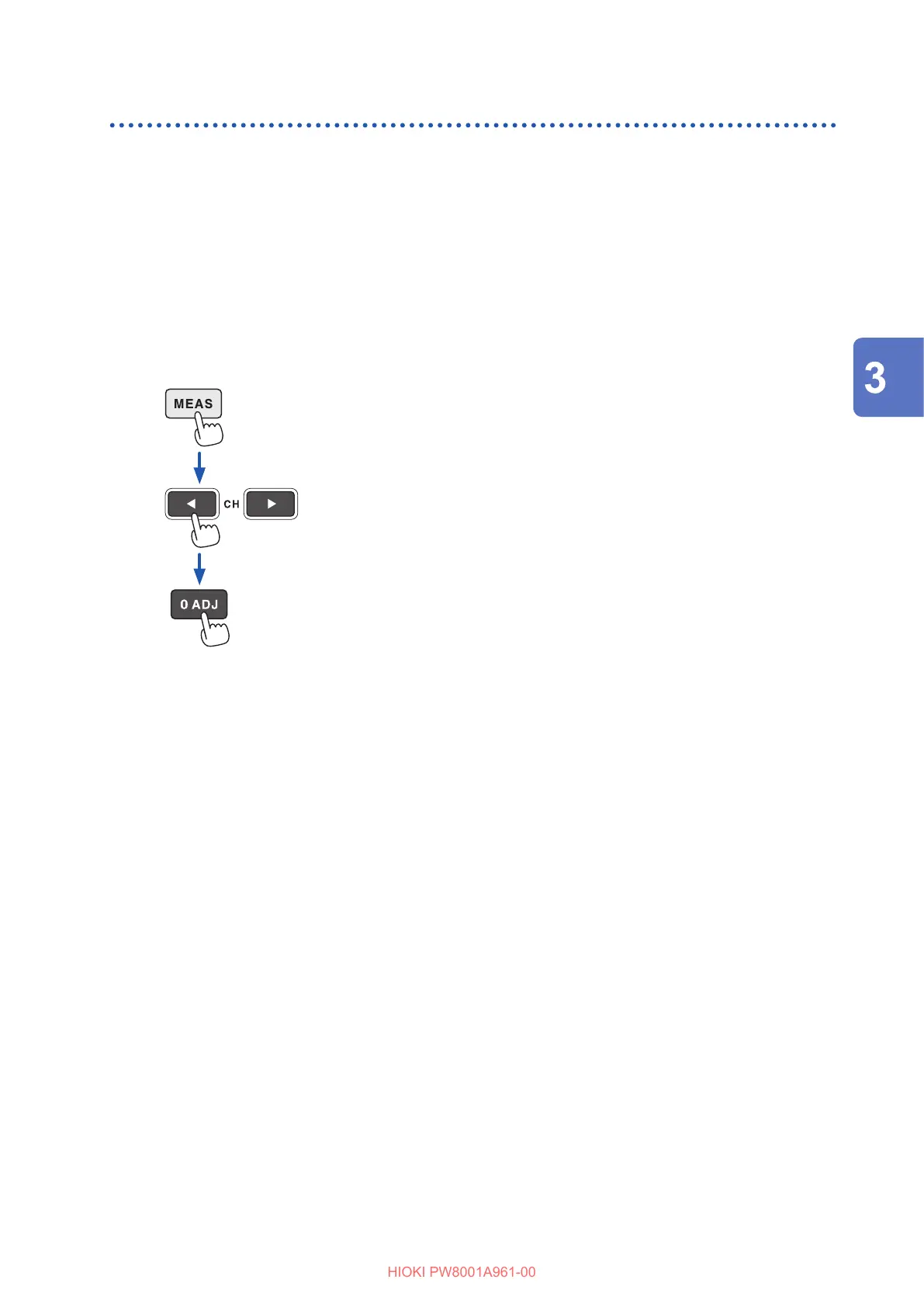

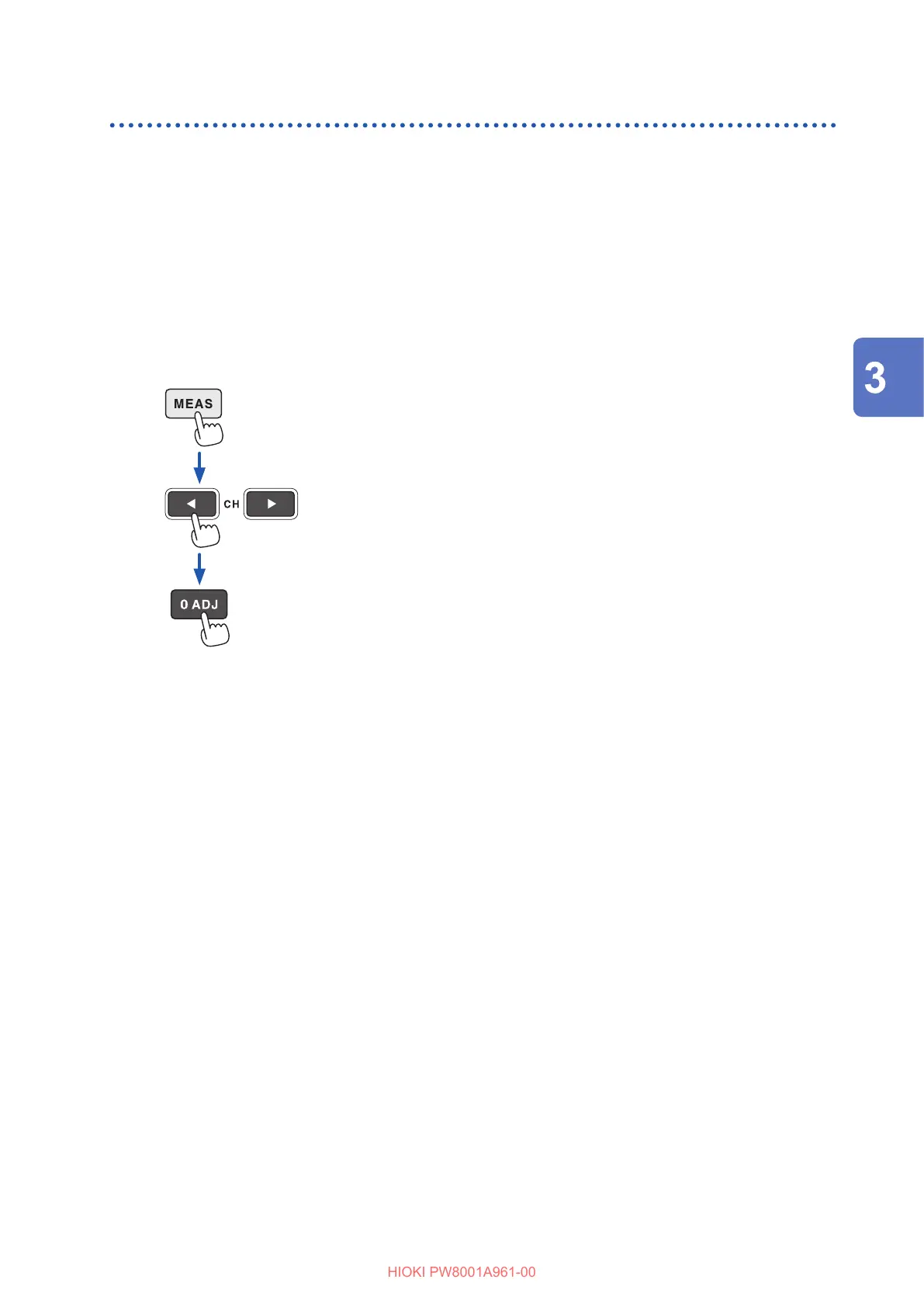

1

Press the MEAS key.

2

Use the CH key for channel selection to switch the

display to [A-D] or [E-H].

The displayed channel will change each time the

CH

keys are

pressed.

3

Press 0ADJ.

The conrmation dialog box will be displayed.

4

Tap [Yes].

Zero adjustment is started.

• When the [A-D] channel indicator or [E-H] channel indicator is lit up, you can also perform motor

input zero adjustment by pressing the 0ADJ key even on any page of the Measurement screen.

• Zero adjustment is unavailable for channels with the input setting set to [Pulse].

• Zero adjustment can be performed within an input range of

±

10% of range. Inputting our-of-range

signals cause zero-adjustment to fail.

Displaying Power Numerically

Loading...

Loading...