WinMax Lathe Conversational Part Programming v546CO Conversational Part Programming 2-19

• SPRING PASSES—identifies the number of repetitions the finish tool will

make at the final finish depth. This field appears when Turn Finish is selected

for the Operation.

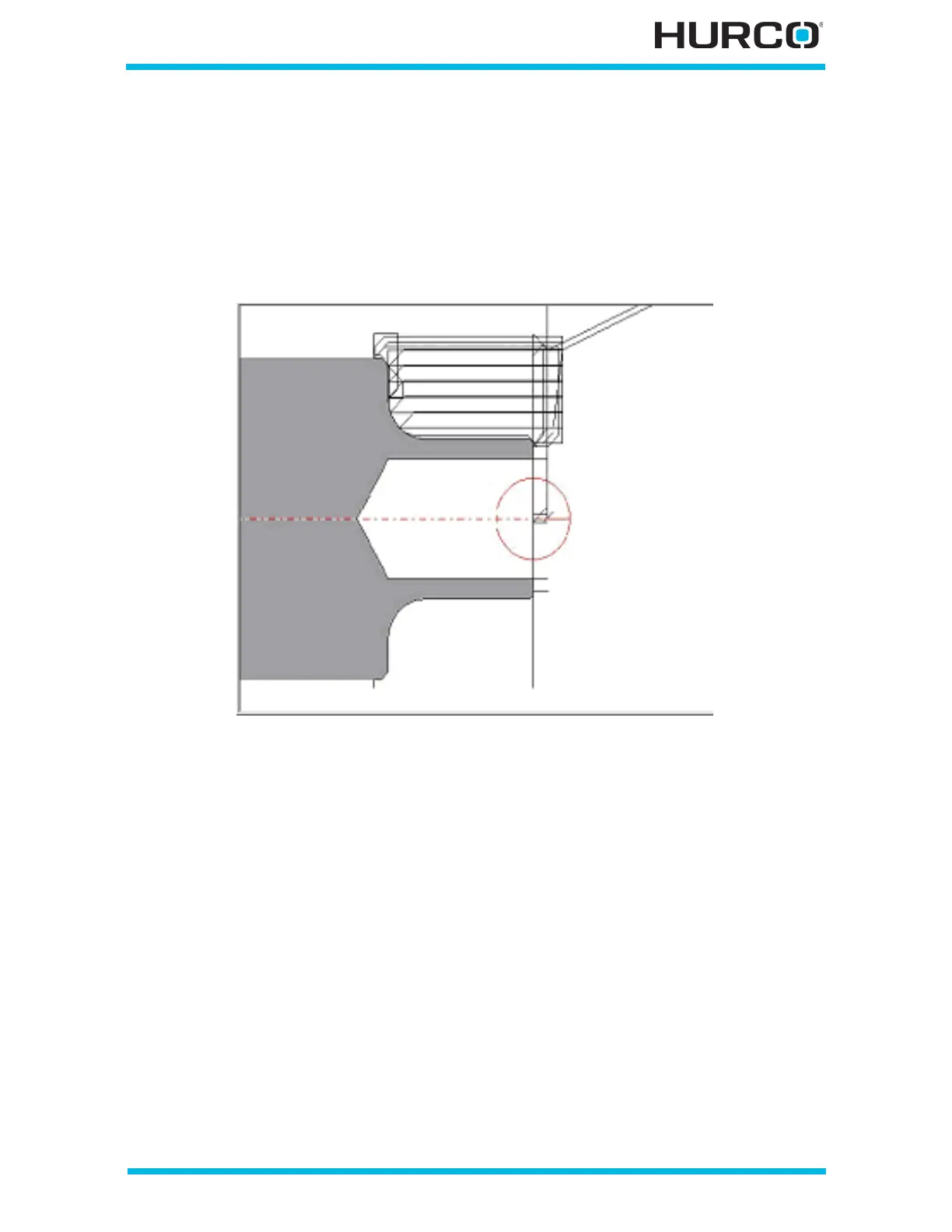

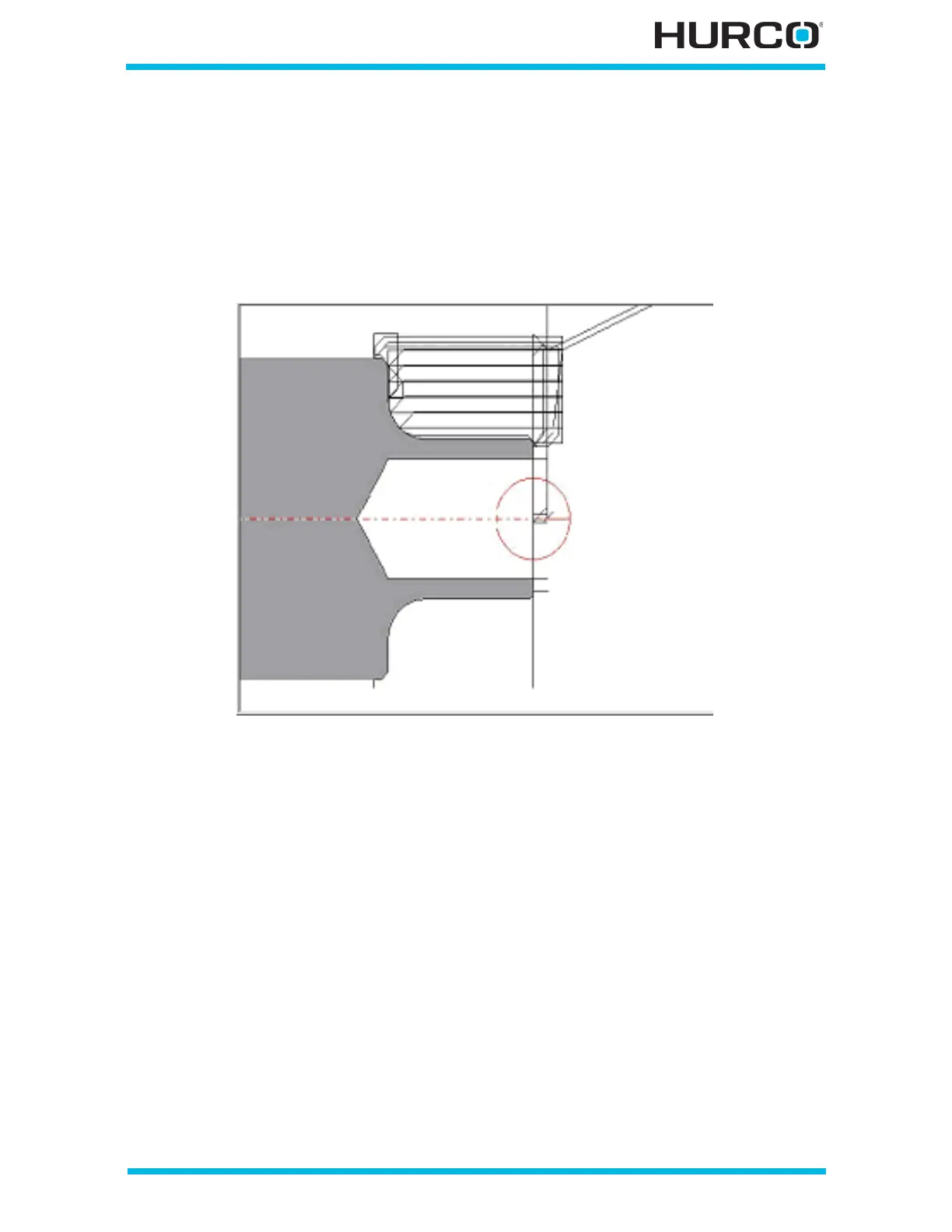

• APPROACH ANGLE—identifies the angle the tool approaches the stock. Used

with the Approach Clearance to determine a vector which defines how the

tool moves toward the beginning of the profile. This field appears when Turn

Finish is selected for the Operation. The figure below shows a 45° approach

angle for each Step:

Figure 2–10. Tool Path 45° Approach Angle

• APPROACH CLEARANCE—identifies the clearance of the tool as it

approaches the stock. Used with the Approach Angle to determine a vector

which defines how the tool moves toward the beginning of the profile. This

field appears when Turn Rough or Turn Finish is selected for the Operation.

• RETRACT ANGLE—pulls the tool off the profile between steps along a vector

in the direction of retract angle if NO is selected for RETRACT ALONG

PROFILE, shown as 2 in Figure 2–12. Groove Operation Cut Clearance and

Retract Clearance example, on page 2 - 21. The default is 45°. This field

appears for all rough and finish operations.

• RETRACT CLEARANCE—identifies the distance that the tool moves away

from the wall, shown as 3 in Figure 2–12. Groove Operation Cut Clearance

and Retract Clearance example, on page 2 - 21, before moving at Rapid to

the start of the next pass. The default is 0.254 mm or 0.010 inch. This field

appears for all rough and finish operations.

• OVERRIDE TOLERANCE—overrides the default tolerance, 0.00254 mm or

0.0001 inch, for elements in the current profile when Yes is selected. The

ELEMENT TOLERANCE field is active when Yes is selected.

Loading...

Loading...