AKD2G-S Installation Manual, Safety 1 | 9 Setup

9.5 Troubleshooting

Drive problems occur for a variety of reasons, depending on the conditions in your installation. The causes of faults

in multi-axis systems can be especially complex. If you cannot resolve a fault or other issue using the

troubleshooting guidance presented below, customer support can give you further assistance.

Eliminate errors and faults in compliance with work safety rules. Troubleshooting only by qualified and

trained staff.

More details on the removal of faults can be found in the WorkBench User Manual.

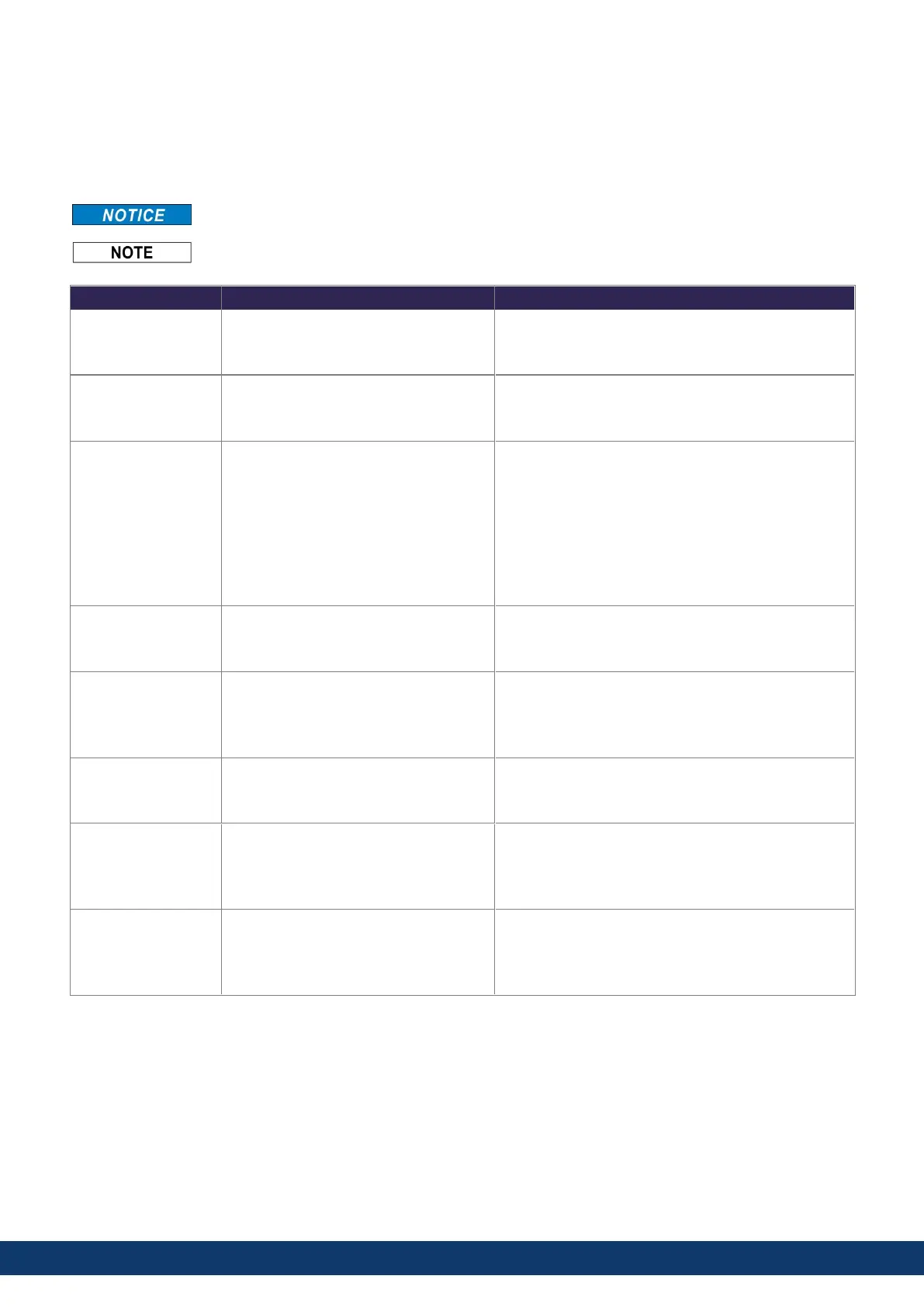

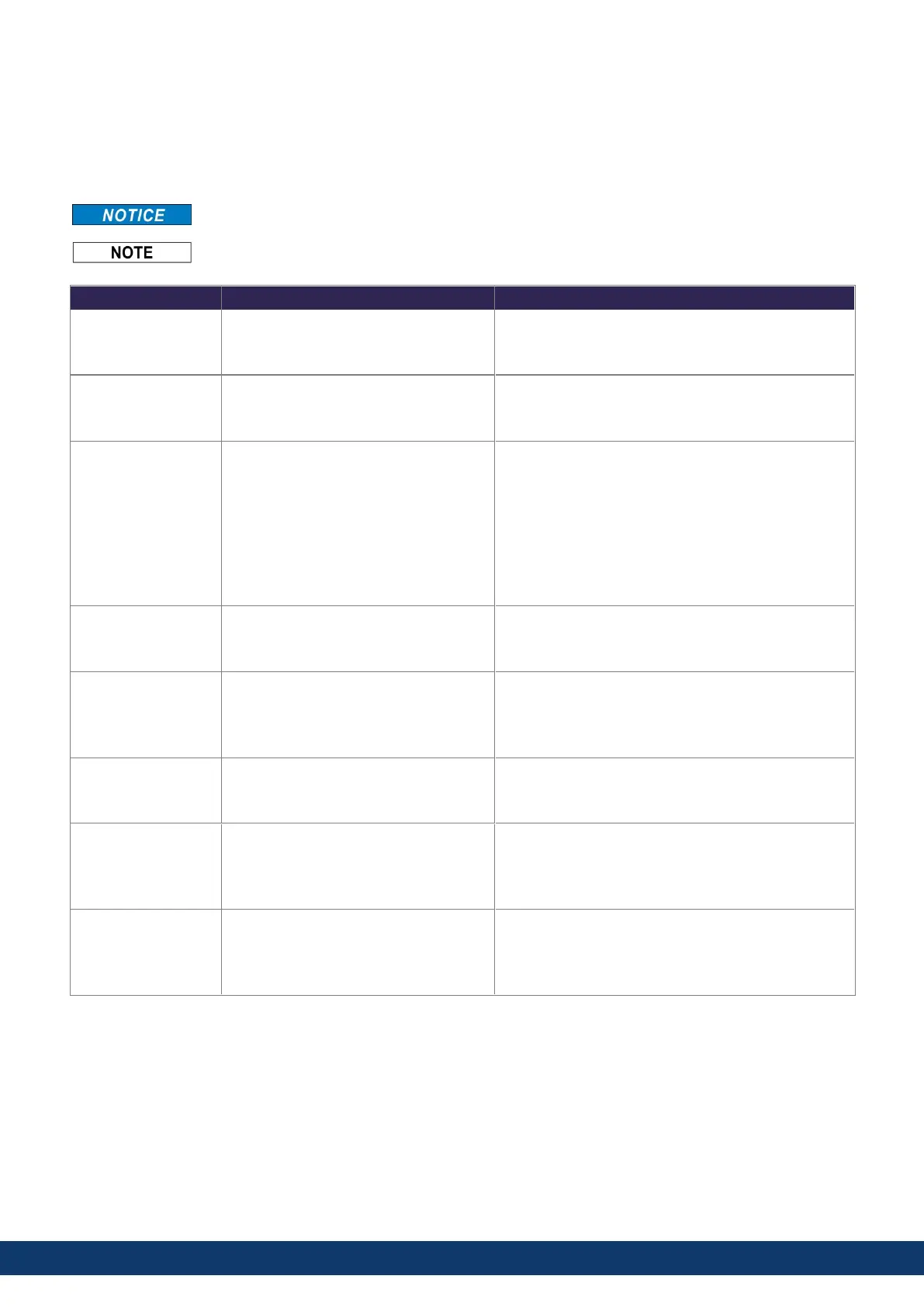

Problem Possible Causes Remedy

HMI message:

Communication fault

1. wrong cable used, cable plugged

into wrong position on drive or PC

2. wrong PC interface selected

1. plug cable into the correct sockets on the drive

and PC

2. select correct interface

Drive does not enable

1. HW Enable configured but not

wired

2. HW or SW Enable not set

1. connect HW Enable to the selected input

2. Apply 24V to HW Enable and select SW Enable

in WorkBench / Fieldbus

Motor does not rotate

1. drive not enabled

2. software enable not set

3. break in setpoint cable

4. motor phases swapped

5. brake not released

6. drive is mechanically blocked

7. motor pole no. set incorrectly

8. feedback set up incorrectly

1. apply ENABLE signal

2. set software enable

3. check setpoint cable

4. correct motor phase sequence

5. check brake control

6. check mechanics

7. set motor pole no.

8. set up feedback correctly

Motor oscillates

1. gain is too high (speed controller)

2. feedback cable shielding broken

3. AGND not wired up

1. reduce AXIS#.VL.KP (speed controller)

2. replace feedback cable

3. join AGND to CNC-GND

Drive reports

following error

1. Irms or Ipeak set too low

2. current or velocity limits apply

3. accel/decel ramp is too long

1. verify motor/drive sizing

2. verify that AXIS#.IL.LIMITN/P,

AXIS#.VL.LIMITN/P are not limiting the drive

3. reduce AXIS#.ACC/AXIS#.DEC

Motor overheating

1. motor operating above its rating

2. motor current settings incorrect

1. verify motor/drive sizing

2. verify motor continuous and peak current

values are set correctly

Drive too soft

1. AXIS#.VL.Kp (velocity) too low

2. AXIS#.VL.Ki (velocity) too low

3. filters set too high

1. increase AXIS#.VL.KP (velocity)

2. increase AXIS#.VL.KI (velocity)

3. refer to documentation regarding reducing

filtering (AXIS#.VL.AR*)

Drive runs roughly

1. AXIS#.VL.Kp (velocity) too high

2. AXIS#.VL.Ki (velocity) too high

3. filters set too low

1. reduce AXIS#.VL.KP (velocity)

2. reduce AXIS#.VL.KI (velocity)

3. refer to documentation regarding increasing

filtering (AXIS#.VL.AR*)

178 Kollmorgen | kdn.kollmorgen.com | June, 2023

Loading...

Loading...