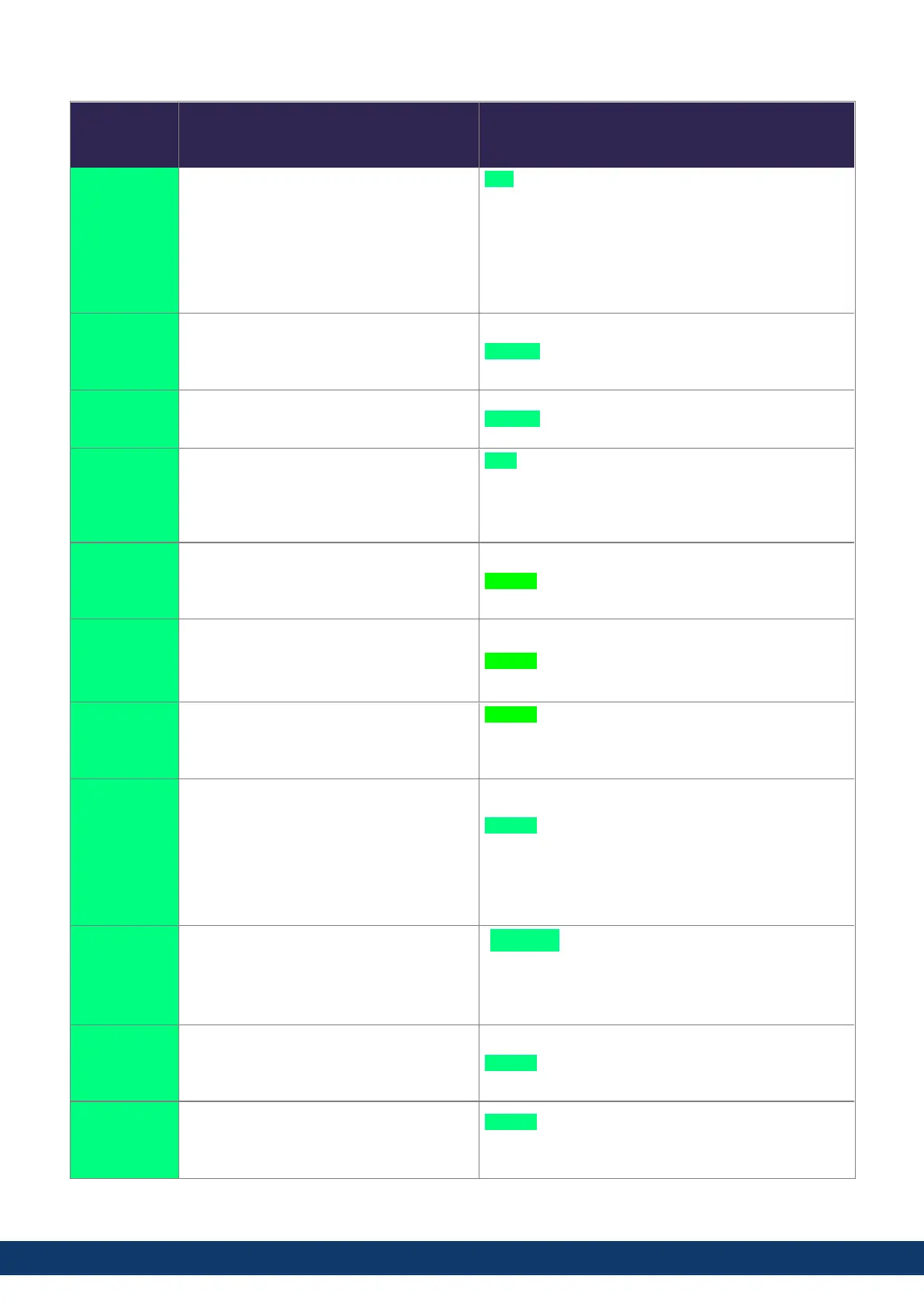

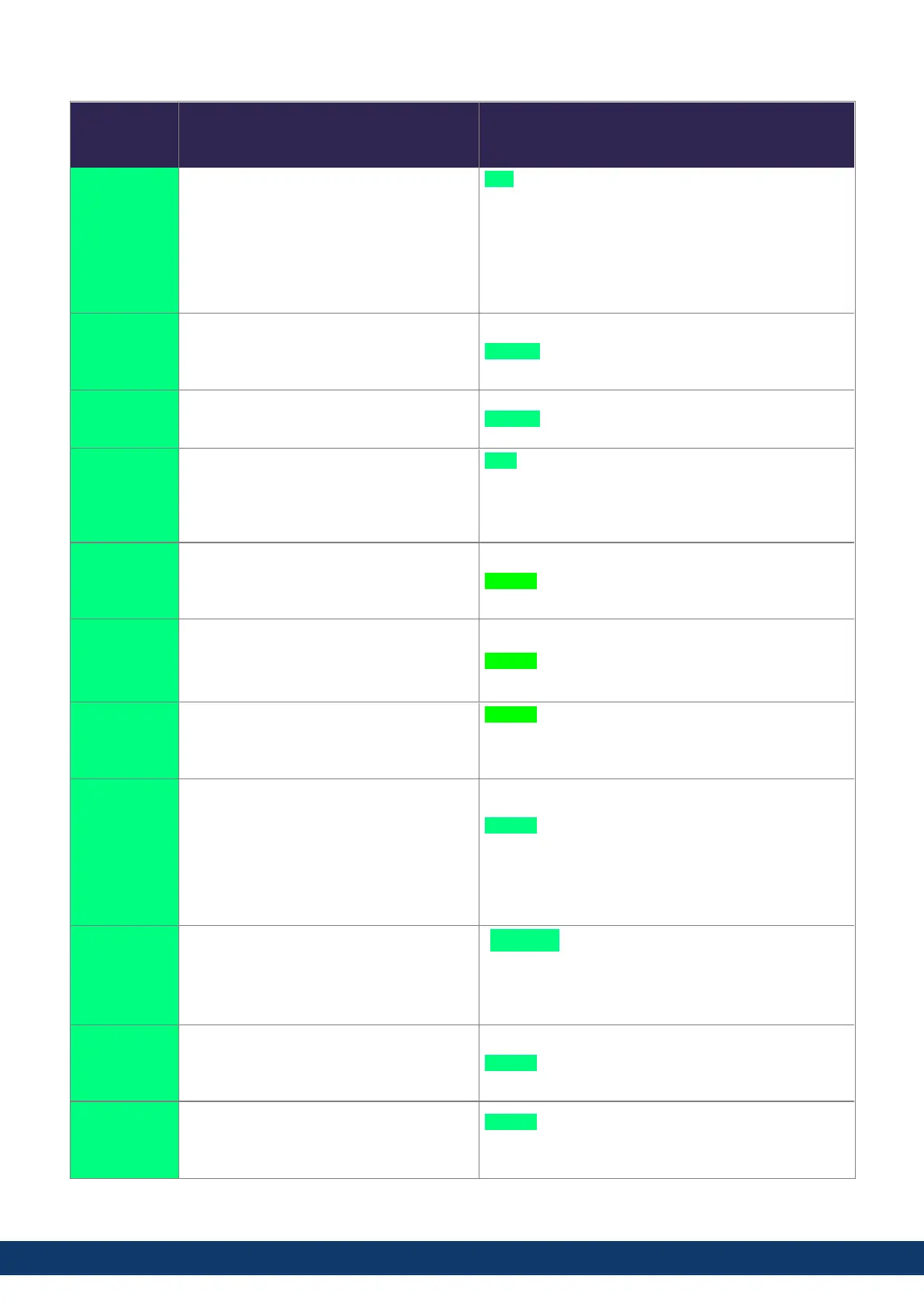

AKD2G-S Installation Manual, Safety 1 | 14 Requirements to User Documentation, Revision 1.12

ID

(green=done

for all FS)

Requirements

Realized

(green=done for FSx)

WI-778

The drive shall be used for the following times:

Mission Time: == 20 years

Proof test interval > 20 years

FS1 (The systematic capability according to IEC 61508 for

the safety-related subsystems of the drive are SC = 2. TM =

20 Years, SFF = 75%., ➜ # 183),

(You must test the STO function after initial start of the axis,

after each intervention into the wiring of the system, or after

exchange of one or several components of the drive

system. The proof test interval is one year to meet the

required PFH., ➜ # 183)

WI-802

The drive and its components shall meet the

following environmental conditions:

Storage condition: Humidity.....

Transportation condition: Humidity....

FS1/2/3 (Enclosure, wiring, ➜ # 182)

WI-805

The drive shall be usable in environments with

a pollution of degree 2 with non conductive

material (according to EN 60664-1)

FS1/2/3 (Pollution level 2 as per IEC 60664-1, ➜ # 182)

WI-834

The safety manual shall require the safety

functions to be validated during installation.

FS1 (Check and verify the STO wiring (examples (➜ #

185)). The installation must be verified by trained personnel

after any changes to the installation. The expertise of the

personnel must beappropriate tothe complexity and safety

integrity level of the drive system., ➜ # 183)

WI-1186

The housing of the drive shall conform the IP

20 as per IEC 60664-1. The user manual shall

require the drive to be placed in an IP54

cabinet.

FS1/2/3 (Enclosure, wiring, ➜ # 182)

WI-1373

The user manual shall require the user to

- avoid shocks while transport

- transport the device only in the manufacturers

packaging

FS1/2/3 (Enclosure, wiring, ➜ # 182)

WI-1739

The help function shall be part of the

certification and handled as part of the safety

manual.

FS1/2/3 , single source, the InstallationManual with

Chapter10= Safety Manual is 100% part of the WorkBench

Help. All SMM SafeGrid help aliases refer to Chapter 10

(Safety Manual) topics.

WI-2174

There shall be a notice in the safety manual,

that even during STO there is the possibility of

high voltages on the power stage and motor

terminals. If there is work on the power

terminals of the drive or the motor, the main

power switch of the electrical installation shall

be switched "off" to ensure high voltages do not

occur on these lines.

FS1/2/3 (Risk of electrical shock! The safety functions do

not provide an electrical separation from the power output.

If manual access to the motor or drive power terminals is

necessary, , ➜ # 180)

WI-2757

The wiring of the digital inputs shall be done

such, that short circuits between the two

channels of a single input are avoided.

FS1/2/3 (When wiring the digital inputs and

outputs, take care that short circuits between

the inputs, outputs, or to supply lines are

avoided., ➜ # 182)

WI-2761

The display content and the usage of the push

button shall be described in the safety manual.

The user shall get an expectation of the

behavior of the HMI before use.

FS1/2/3 (Settings , ➜ # 189)

WI-2806

Parameterizing of the SMM shall be done by

trained personnel only. The level of experience

shall beappropriate tothe complexity and

safety integrity level of the drive system.

FS1/2/3 (Parameterizing Functional Safety: only by trained

personnel with expertise appropriate tothe complexity and

safety integrity level of the drive system., ➜ # 180)

206 Kollmorgen | kdn.kollmorgen.com | June, 2023

Loading...

Loading...