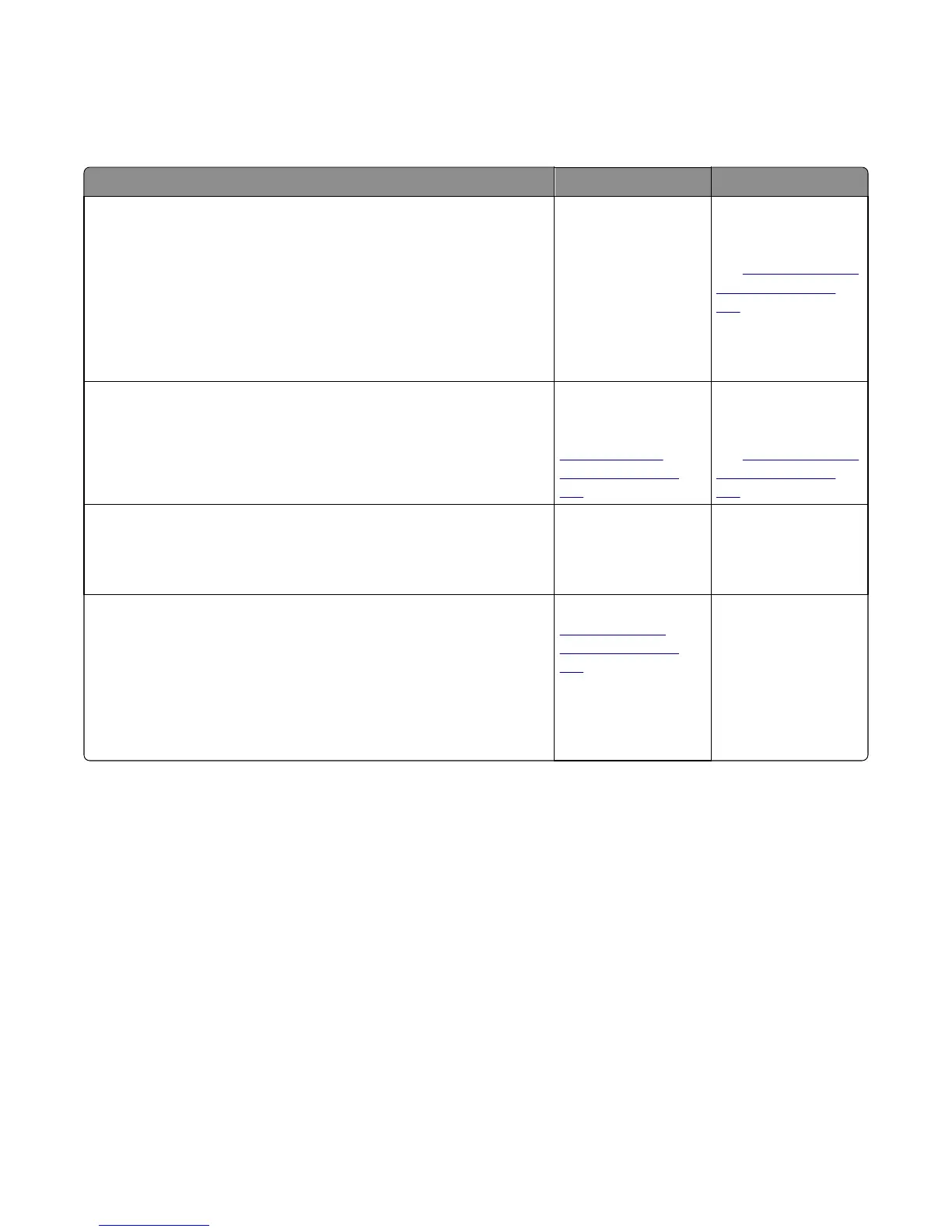

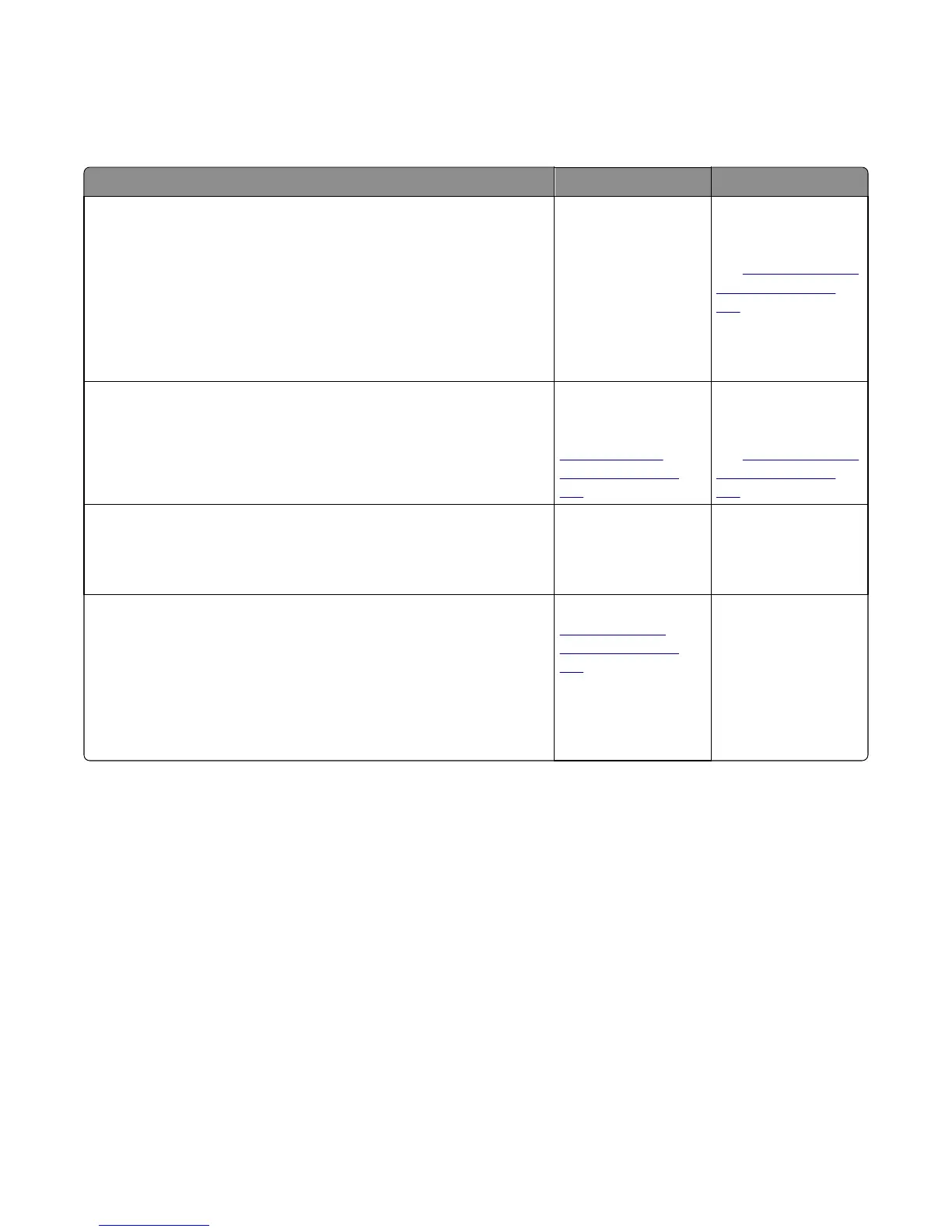

Residual image check

Service tip: The primary cause of random marks is due to loose material moving around inside the printer and attaching

to the photoconductor unit, developer roll, or transfer belt.

Actions Yes No

Step 1

Check the condition of the imaging unit using the customer menus

(administration menus):

a At the Ready prompt, press Menu.

b Select Supplies Menu, and press Select.

c Select Imaging Kit, and press Select.

Does the display indicate OK?

Go to step 2. Replace the imaging

unit or the

photoconductor unit.

See

“Imaging unit (IU)

removal” on page

246.

Step 2

Measure the distance from the original image to the same point on the

residual image.

Is the distance 43.9 mm?

Replace the developer

corresponding to the

color of the image. See

“Developer unit

removal” on page

238.

Replace the imaging

unit or the

photoconductor unit.

See

“Imaging unit (IU)

removal” on page

246.

Step 3

Is the distance between the original image and the residual image 94.2

mm?

Replace the

photoconductor.l.

Go to step 4.

Step 4

Run the Menu Setting Page twice to clear any debris.

a Press Menu on the control panel.

b Select Reports from the Admin Menu, and press Select.

c Select Imaging Kit, and press Select.

Is there still any toner contamination on the fuser assembly?

Replace the fuser. See

“Fuser assembly

removal” on page

267.

Contact your next level

of support.

Solid color pages check

Service tip: A solid color page is generally caused by a problem in the high‑voltage power supply or an incorrect high

voltage in the printing process resulting in toner development on the entire photoconductor.

5027

Diagnostic information

43

Loading...

Loading...