Preventive Maintenance ASAP 2460 Operator’s Manual

7-18 246-42800-01 - Aug 2013

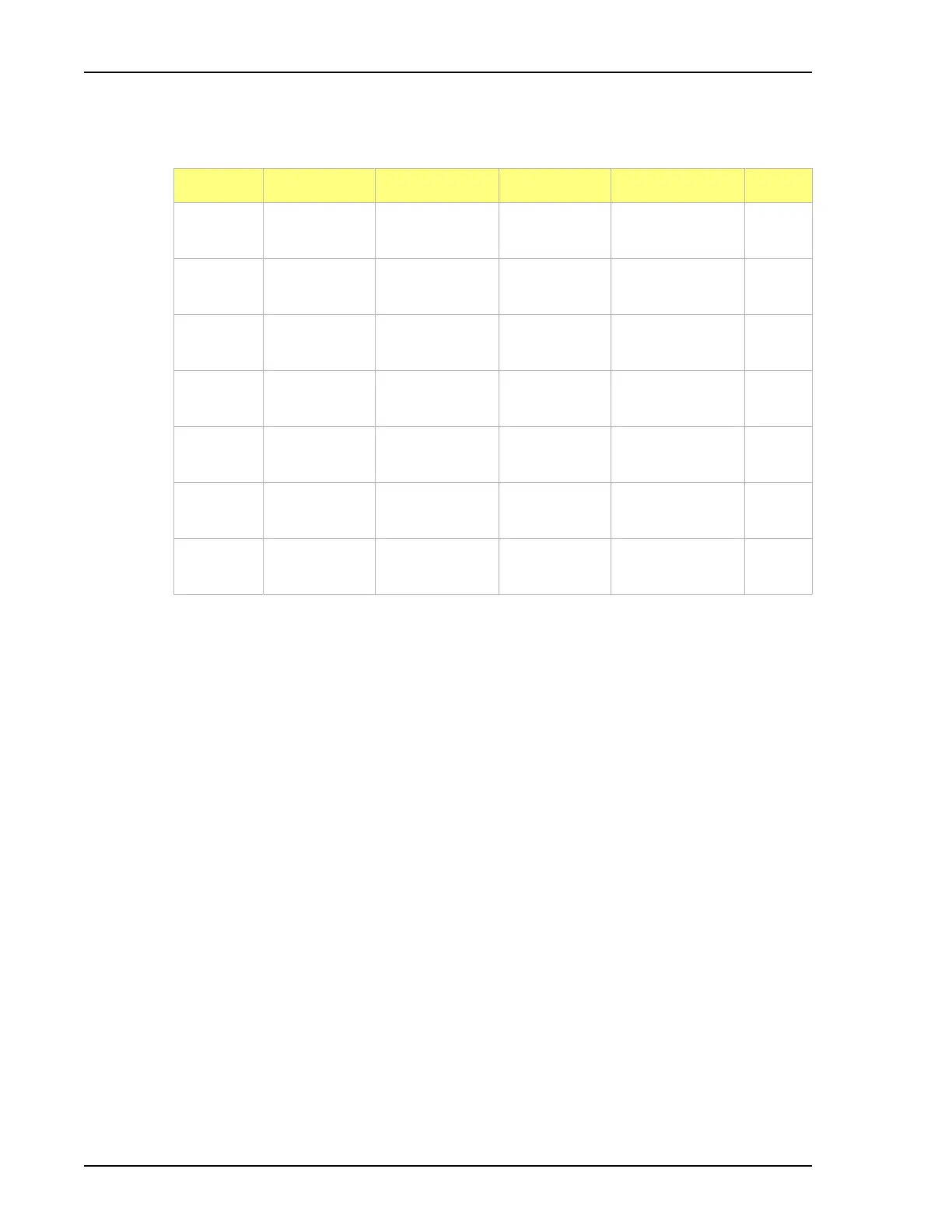

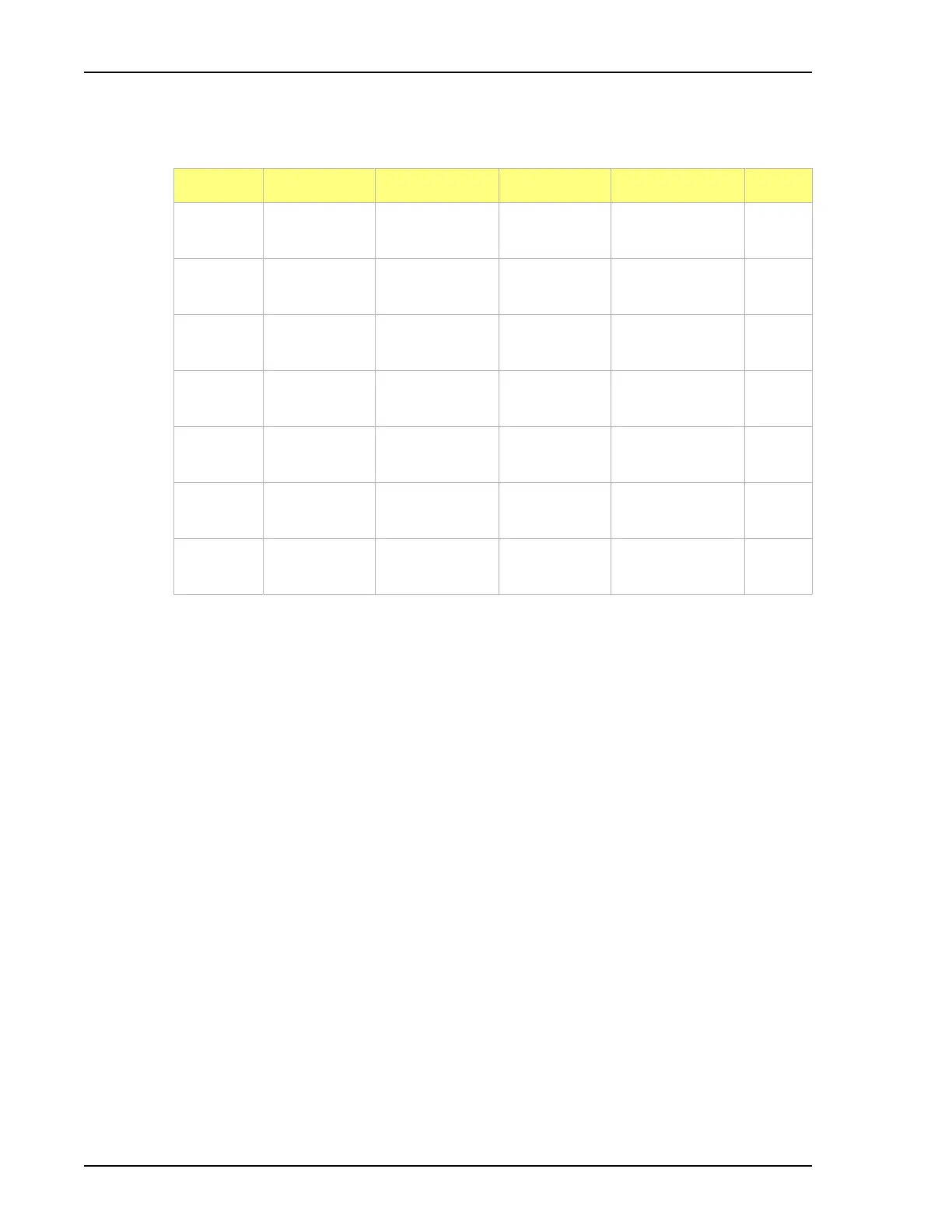

8. Close valves 8 and 18, and record the pressure as the Initial Reading for Inlet Ports in the table

below.

9. Wait 3 minutes, then record the pressure as the 3 Minute Reading in the table above.

10. Subtract the first reading from the second reading and record in the Difference column in the

table above.

11. If the value in the Difference column is at or below the value in the Limits column, enter Yes in

the OK? column. If the Difference value is not below the Limits value, a gas inlet valve, inlet

plug, or gas line is leaking from atmosphere.

12. Close all gas inlet manifold valves (21 through 26).

13. Record the pressure as the Initial Reading, then begin timing as soon as you complete the next

step.

14. Gas inlet valves 21 through 26 must remain closed during this procedure. Pressurize the inlet to

valve 21 by opening the supply valve or removing the port plug. This allows gas or air to

pressurize the inlet valve above the seat.

15. After 3 minutes, record the pressure as the 3 Minute Reading. Subtract the first reading from the

second and record in the Difference column in the table above.

16. Repeat steps 13 through 15 for the inlet valves 22 through 26.

Test Initial Reading 3 Min. Reading Difference Limits OK?

Inlet Ports

30 microns

(0.3 mmHg)

Valve 21

2.1 microns

(0.0021 mmHg)

Valve 22

2.1 microns

(0.0021 mmHg))

Valve 23

2.1 microns

(0.0021 mmHg)

Valve 24

2.1 microns

(0.0021 mmHg)

Valve 25

2.1 microns

(0.0021 mmHg)

Valve 26

2.1 microns

(0.0021 mmHg)

Loading...

Loading...