No. 99MBG518A

A-10

PART A : 4 Hardness Test Methods

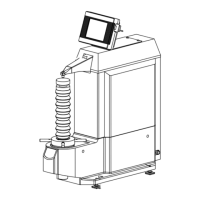

■FigureoftheprincipleofRockwellhardnessandRockwellsupercial

hardness

7

1

F

0

F

0

+F

1

8

7

F

0

6

2

4

3

7

RockwellhardnessorRockwellsupercialhardness=

h

S

N –

X: Time 4: Depth of permanent indent h

Y: Position of indenter 5: Specimen surface

1: Depth of indent with preliminary test force F

0

6: Reference surface for measuring the depth

of permanent indent

2: Depth of indent with additional test force F

1

3: Elastic recovery after eliminating additional

test force F

1

7: Position of indenter

8: Curve of indent depth and time

4.1.2 PrecautionsfortheRockwell/RockwellSupercialHardness

Test

■Test surface

Thetestsurfaceshouldbeaatsurfaceatarightangletothedirectionofthetestforce.Unlessthe

standardfortheproductormaterialspeciesotherwise,thetestsurfaceshouldbesmoothwithout

roughness,withnooxidelm,foreignsubstanceandparticularlynolubricantapplied.

■Distance to the edge of the specimen from the center of the indent

The distance between the center points of two adjacent indents needs to be at least three times the

indent diameter. The distance from the center point of the indent to the edge of the specimen should be

at least two and a half times the indent diameter.

Loading...

Loading...