Do you have a question about the Mitutoyo HR-530 Series and is the answer not in the manual?

| Display | LCD |

|---|---|

| Resolution | 0.1 HR |

| Rockwell Scales | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV |

| Superficial Rockwell Scales | 15N, 30N, 45N, 15T, 30T, 45T |

| Vickers Scales | HV |

| Brinell Scales | HB |

| Data Output | RS-232C |

| Power Supply | AC 100-240V, 50/60Hz |

| Operating Temperature | 10 to 35 °C |

| Type | Digital Rockwell Hardness Tester |

Explains safety symbols and warnings for potential hazards.

Details symbols for prohibited and mandatory actions.

Explains symbols for referential information and locations.

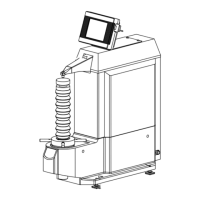

Illustrates the main unit and locations of safety labels.

Details the meaning and precautions for each product safety label.

Provides safety guidelines for the LED illumination unit.

Outlines general safety warnings and precautions for product operation.

Specifies product applications and handling care.

Lists environmental requirements for product installation.

Specifies requirements for the power cable.

Warns against removing covers and disassembling the product.

Advises on shielding measures in specific locations.

Warns about potential hazards during workpiece replacement.

Explains the influence of magnetic forces on test results.

Provides guidelines for relocating the testing machine.

Product compliance with EU EMC Directive.

Information on Japanese export control regulations for the product.

Requirements for exporting to EU member countries.

Guidelines for product disposal outside the EU.

Information on WEEE Directive compliance for disposal.

Product compliance with China RoHS requirements.

Details the product warranty terms and conditions.

States Mitutoyo's liability limitations for product use.

Identifies the target audience and purpose of the manual.

Explains the meaning of brackets and marks used in the document.

Details the Rockwell and Rockwell Superficial hardness test methods.

Explains the Brinell hardness test method and its application.

Describes the plastic hardness test method.

Details the Indent Depth Brinell Hardness Test (HBT).

Explains the operational flow for Rockwell and Plastic hardness tests.

Explains the procedure for testing one point.

Details setting up groups and testing multiple points.

Explains how to fix test positions and perform tests.

Details how to execute continuous tests.

Explains the test flow for Indent Depth Brinell Hardness Test.

Explains the procedure for testing one point.

Details setting up groups and testing multiple points.

Explains the contents related to screens.

Explains settings for test conditions.

Explains settings for execution conditions.

Explains how measurement results are displayed.

Explains system condition settings.

Explains button functions on the home screen.

Describes the standard home screen display and its elements.

Describes the simple home screen display for large judgments.

Displays test results for multiple points and the average value.

Displays current and previous test results in a list.

Describes the multi-test screen when a Jominy table is connected.

Covers changing scale settings for test methods.

Explains indenter selection for Brinell hardness tests.

Details scale, indenter, and test force settings for plastic tests.

Details scale, indenter, and test force settings for ASTM D785-B.

Covers scale, indenter, and test force settings for HBT.

Details test force and time settings.

Corrects tests for curved specimens (cylindrical or spherical).

Performs multi-point correction and shift correction.

Supports eight types of hardness conversion tables.

Specifies GO/NG judgment settings on the [GO/NG] screen.

Groups multiple results and calculates average, excluding max/min.

Sets output methods to external devices (USB, Serial, SPC, USB memory).

Lists settings specified in the execution conditions.

Displays results from statistical calculation.

Displays test results in a list.

Displays statistical calculation results (max, min, avg, etc.).

Displays test results in a list format.

Displays a hardness chart (line graph).

Displays a histogram of hardness values.

Specifies graph display settings for the line graph.

Specifies graph display settings for the histogram.

Displays X-R graphs for group measurement analysis.

Displays detailed data for selected test results.

Derives relationship between specimen thickness and hardness.

Allows selection and highlighting of the test method button.

Selects display style of the home screen and other display settings.

Controls equipment settings like Admin. mode, Beep, and Sleep.

Configures version, loading count, language, time, and maintenance.

Provides procedures for daily and prolonged storage of the machine and test block.

Recommends regular inspections by a Mitutoyo service engineer.

Explains how to inspect and replace consumable parts.

Provides solutions for common system operation problems.

Provides solutions for issues encountered during hardness testing.

Lists error messages and recommended actions to resolve them.

Details the main unit's hardness test functions and specifications.

Specifies the maximum dimensions and mass of the specimen.

Lists other specifications like external output, power, and dimensions.

Lists standard accessories with their part numbers and specifications.

Lists optional accessories available for purchase.

Lists various specimen stages and their specifications.

Lists compatible printer models and cables.

Lists other optional accessories like steel stand and foot switch.

Lists various hardness test blocks with specifications.

Lists various types of indenters with specifications and part numbers.

Lists optional accessories specifically for Brinell/HBT hardness tests.

Guides on connecting and setting up the DP-1VA LOGGER printer.

Details options for outputting data externally.

Explains serial output to a receipt printer.

Details PC connection via USB for EXPAK software.

Explains Digimatic interface connection for SPC output.

Provides examples of serial interface data output formats.

Explains output data fields for test results.

Provides an example of statistical result output format.

Provides conversion tables for various hardness scales.

Conversion table for Mitutoyo Hard Steel.

Conversion table for Mitutoyo Soft Metal.

Provides conversion data based on ASTM E140 Table 2.

Provides conversion data based on ASTM E140 Table 4.

Provides conversion data based on ISO 18265 Table A.1.

Provides conversion data based on BS 860 Tables 2,3,4.

Loading...

Loading...