xv

No. 99MBG518A

4 Hardness Test Methods ……………………………………………………………… A-9

4.1 Rockwell/RockwellSupercialHardnessTest ………………………………… A-9

4.1.1 AbouttheRockwell/RockwellSupercialHardnessTest …………………………… A-9

4.1.2 PrecautionsfortheRockwell/RockwellSupercialHardnessTest …………………A-10

4.1.3 TestForce(Rockwell/RockwellSupercialHardnessTest) ………………………… A-11

4.2 Brinell Hardness Test ……………………………………………………………A-12

4.2.1 About the Brinell Hardness Test ………………………………………………………… A-12

4.2.2 Precautions for the Brinell Hardness Test …………………………………………… A-12

4.2.3 Test Force (Brinell Hardness Test) ……………………………………………………… A-13

4.3 Plastic Hardness Test …………………………………………………………… A-14

4.3.1 About the Plastic Hardness Test ………………………………………………………A-14

4.3.2 Precautions for the Plastic Hardness Test …………………………………………… A-14

4.3.3 Test Force (Plastic Hardness Test) ……………………………………………………A-14

4.4 Indent Depth Brinell Hardness Test (HBT) ……………………………………A-15

4.4.1 About the Indent Depth Brinell Hardness Test (HBT) ………………………………… A-15

PART B Installation

1 Installation Environment …………………………………………………………… B-1

1.1 Temperature Range ……………………………………………………………… B-1

1.2 Humidity Range ………………………………………………………………… B-1

1.3 Vibration …………………………………………………………………………… B-1

1.4 Air Currents/Noise ……………………………………………………………… B-2

1.5 Dust ………………………………………………………………………………… B-2

1.6 Power Supply …………………………………………………………………… B-3

1.7 Grounding ………………………………………………………………………… B-4

1.8 Altitude …………………………………………………………………………… B-4

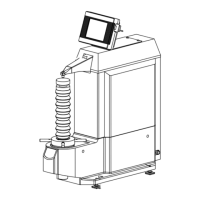

2 Installation Space ……………………………………………………………………… B-5

3 Checking the Levelness of the Testing Machine ………………………………… B-7

4 Connection of Various Cables ……………………………………………………… B-9

4.1 Full System Connection ………………………………………………………… B-9

4.2 Connecting the Printer (DP-1VA LOGGER) ……………………………………B-10

4.3

Connecting the Fine-Adjustment Table for Jominy Testing and the Foot Switch

… B-11

5 ProceduretoAxtheProtectiveSheetfortheDisplayUnit …………………B-13

5.1 ProceduretoAxtheProtectiveSheetfortheDisplayUnit ………………… B-13

Loading...

Loading...