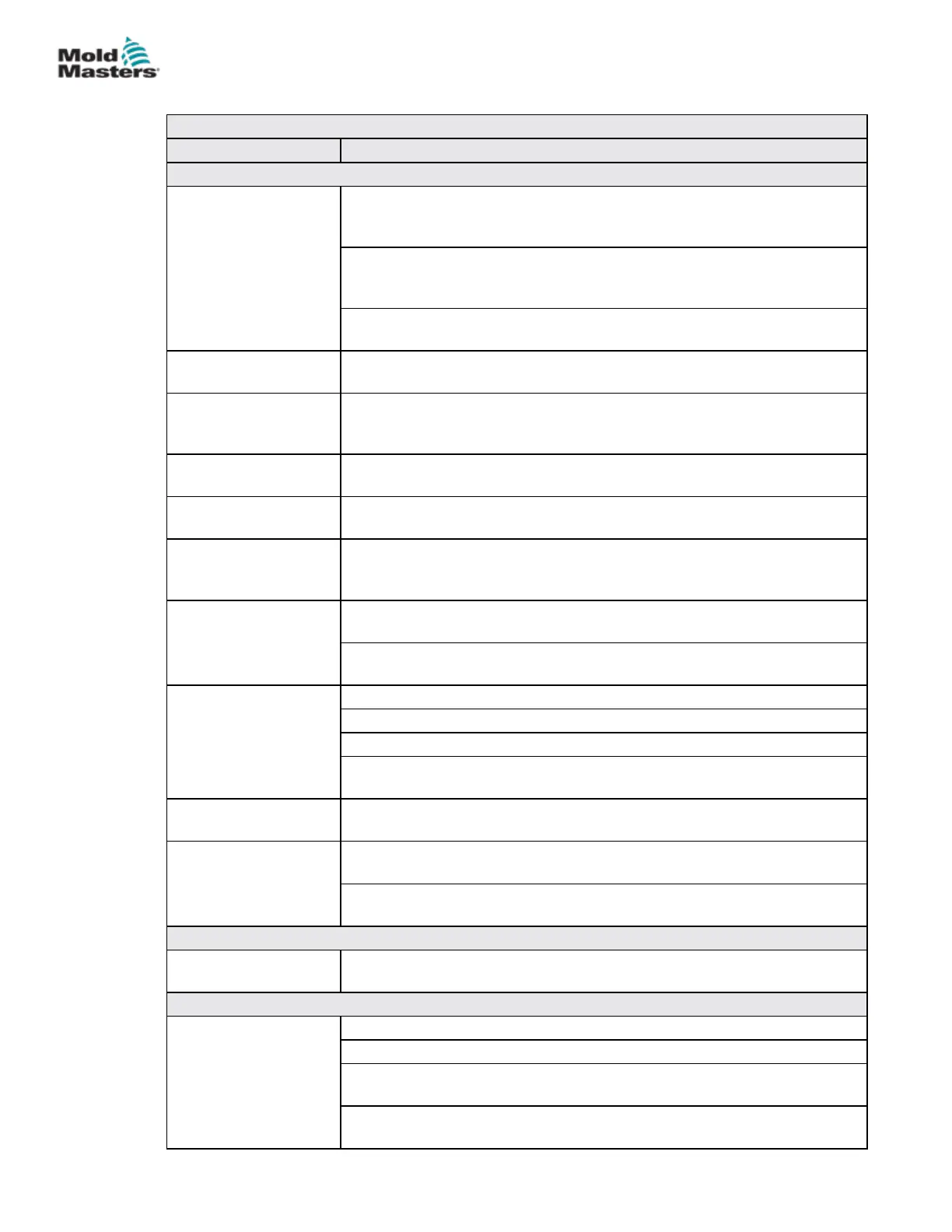

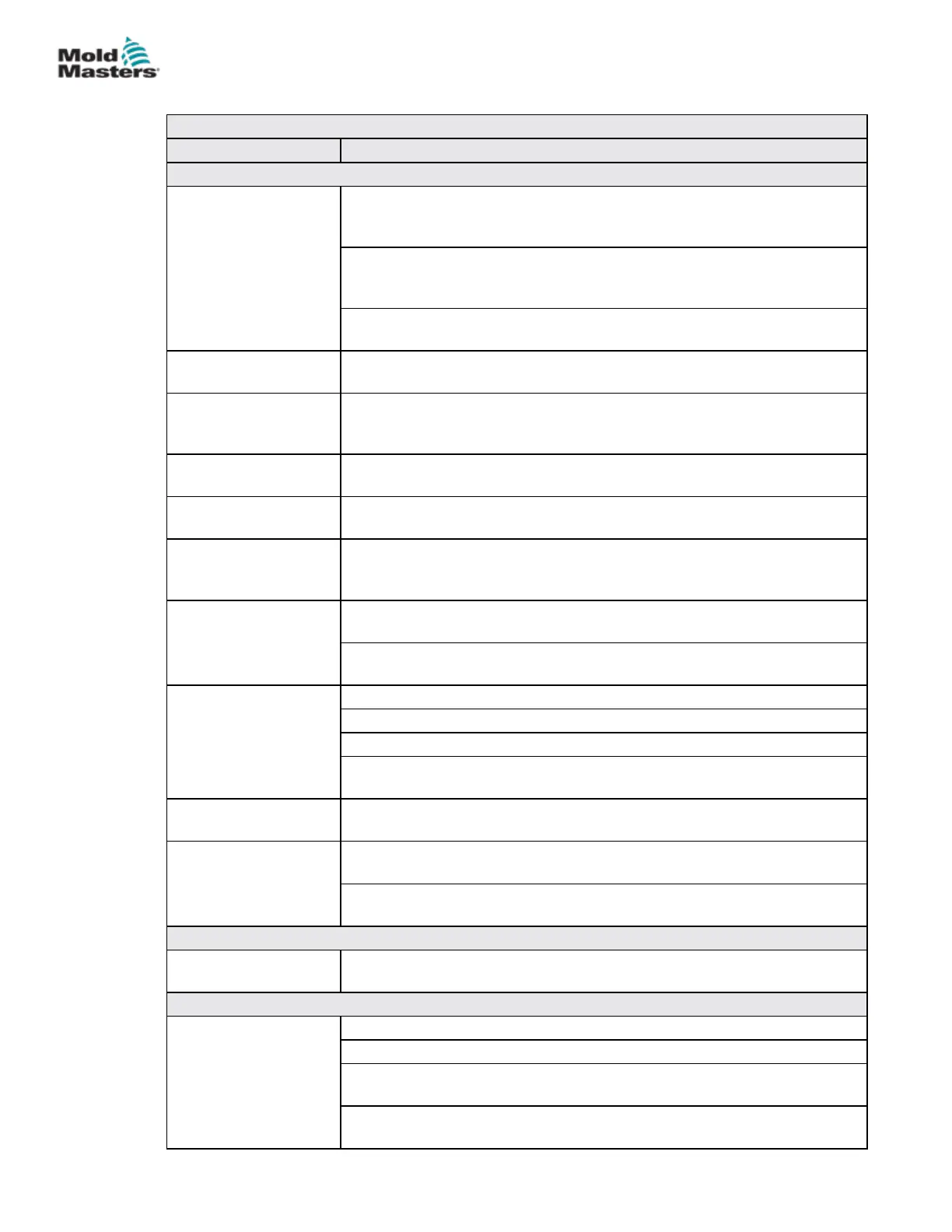

Table 3-5 E-Multi Injection Unit Safety Hazard Details

Hazard Type Potential Hazards

Mechanical Hazards

Body Crushing

Hazard

End of motor moves back during operation. A hazard may exist between

the end of the injection unit motor assembly and a nearby solid obstacle.

Ensure proper guarding as part of integration.

During installation of the E-Multi injection unit onto a mold, a crushing

hazard exists between the adapter plate and the mounting surface of the

mold.

A crushing hazard exists between nozzle and mold melt inlet during

carriage forward motion.

Shearing Hazard A possible shearing hazard exists between the edge of the injection guard

and the injection housing during injection.

Cutting Hazard For horizontally-mounted machines with a high center line height, a

person's head could hit the end of the injection unit causing a cut. Ensure

proper guarding.

Entanglement Hazard

(Belt Drive)

A person could become entangled in the drive belt or screw of the injection

unit. Always keep guards in place.

Entanglement Hazard The open feed port could present an entanglement hazard. Always keep

guards in place.

Cutting or Severing

Hazard

For units equipped with a servo carriage, a severing hazard may exist

between the barrel assembly and support beam when the carriage moves

forward and the hard stop extension in the trunnion slot is not installed.

High Pressure Fluid

or High Temperature

Molten Material

Splashing Hazard

High pressure uid or high temperature molten material may spray from

the nozzle. Always use personal protective equipment (PPE).

High pressure material or high temperature molten material may spray

from a blocked feed port. Always use personal protective equipment.

Loss of Stability Injection unit could fall over if improperly installed on stand.

Injection unit could fall over if transported on stand castors.

Injection unit could fall from top of mold if not properly secured.

Injection unit could fall over if stored vertically on the oor or a table

without adequate support.

Trip Hazard Controller cables are a tripping hazard on the oor between the controller

and the press or E-Multi injection unit.

Stored Energy There could be stored energy in compressed material which is not

released when the machine is powered o.

When installed vertically and powered o, there is stored energy in the

injection assembly which could move downwards.

Electrical Hazard

Contact of Persons

with High Voltage

Heaters, servo motors and electrical components in the controller could

come in contact with a person. Do not remove covers when energized.

Thermal Hazards

Possible Contact of

Persons with High

Temperature Material

The injection barrel could result in burns.

Melted material during routine purging could cause burns.

Hot material or gases could be released from the feed port when clearing

a blockage.

The electric servo motors could overheat presenting a hot surface which

could cause burns to someone touching it.

3.11 E-Multi Injection Unit Safety Hazards

3-16

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

SAFETY

E-Multi Controller User Manual

Loading...

Loading...