- 175 -

8.1.3 Replacement of Vulnerable Components

Vulnerable components of the controller include the cooling fan and filter electrolytic

capacitor. Their service life is related to the operating environment and maintenance.

The service life of the two components is listed in the following table.

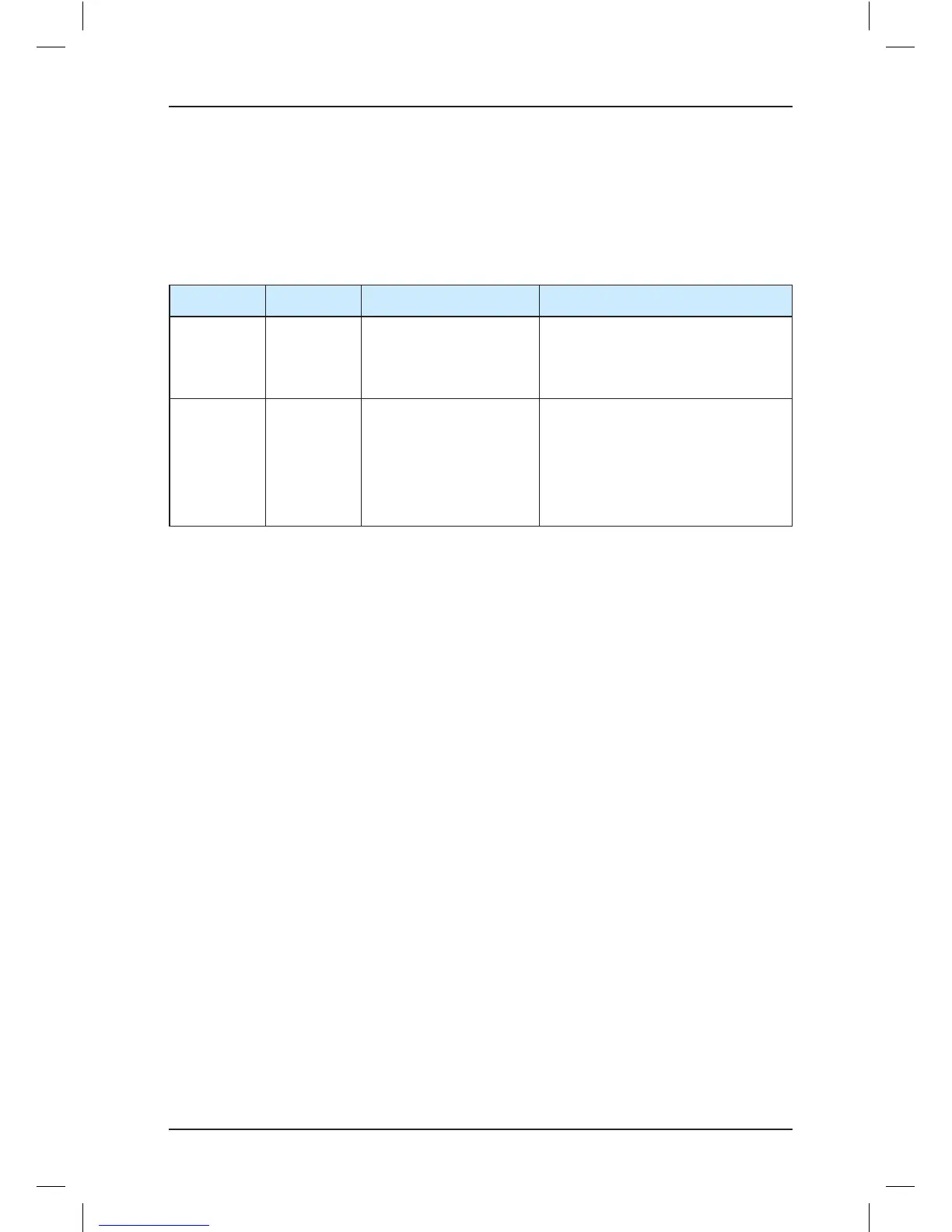

Table 8-1 Service life of cooling fan and lter electrolytic capacitor

Component Service Life Possible Damage Cause Judging Criteria

Fan 2 to 3 years

•

Bearing worn

•

Blade aging

•

Check whether there is crack on

the blade.

•

Check whether there is abnormal

vibration noise upon startup.

Electrolytic

capacitor

4 to 5 years

•

Input power supply in

poor quality

•

High ambient

temperature

•

Frequent load jumping

•

Electrolytic aging

•

Check whether there is liquid

leakage.

•

Check whether the safety valve

has projected.

•

Measure the static capacitance.

•

Measure the insulating resistance.

The service life is obtained based on the following conditions:

•

Ambient temperature: average 30°C per year

•

Load rate: below 80%

•

Running time: less than 20 hours per day

8.1.4 Storage of the Controller

For storage of the controller, pay attention to the following two aspects:

1. Pack the controller with the original packing box provided by Monarch.

2. Long-term storage degrades the electrolytic capacitor. Thus, the controller must be

energized once every 2 years, each time lasting at least 5 hours. The input voltage must

be increased slowly to the rated value with the regulator.

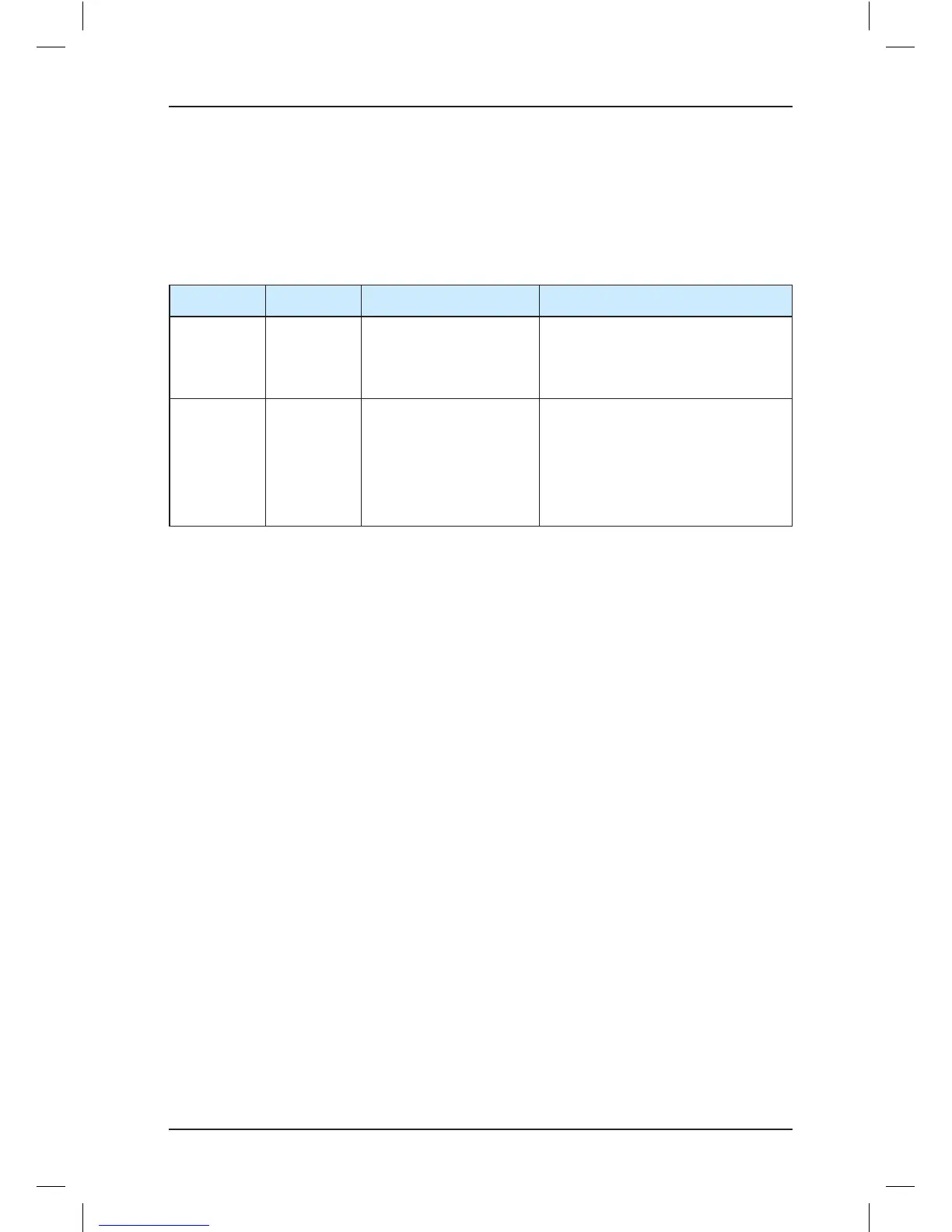

8.2 Description of Fault Levels

The NICE1000

new

has almost 60 pieces of alarm information and protective functions. It

monitors various input signals, running conditions and feedback signals. If a fault occurs, the

system implements the relevant protective function and displays the fault code.

The controller is a complicated electronic control system and the displayed fault information

is graded into ve levels according to the severity. The faults of different levels are handled

according to the following table.

Loading...

Loading...