- 18 -

3. Motor insulation test

Perform the insulation test when the motor is used for the rst time, or when it is reused

after being stored for a long time, or in a regular check-up, in order to prevent the poor

insulation of motor windings from damaging the controller. The motor must be disconnected

from the controller during the insulation test. A 500-V mega-Ohm meter is recommended for

the test. Ensure that the insulation resistance is not less than 5 MΩ.

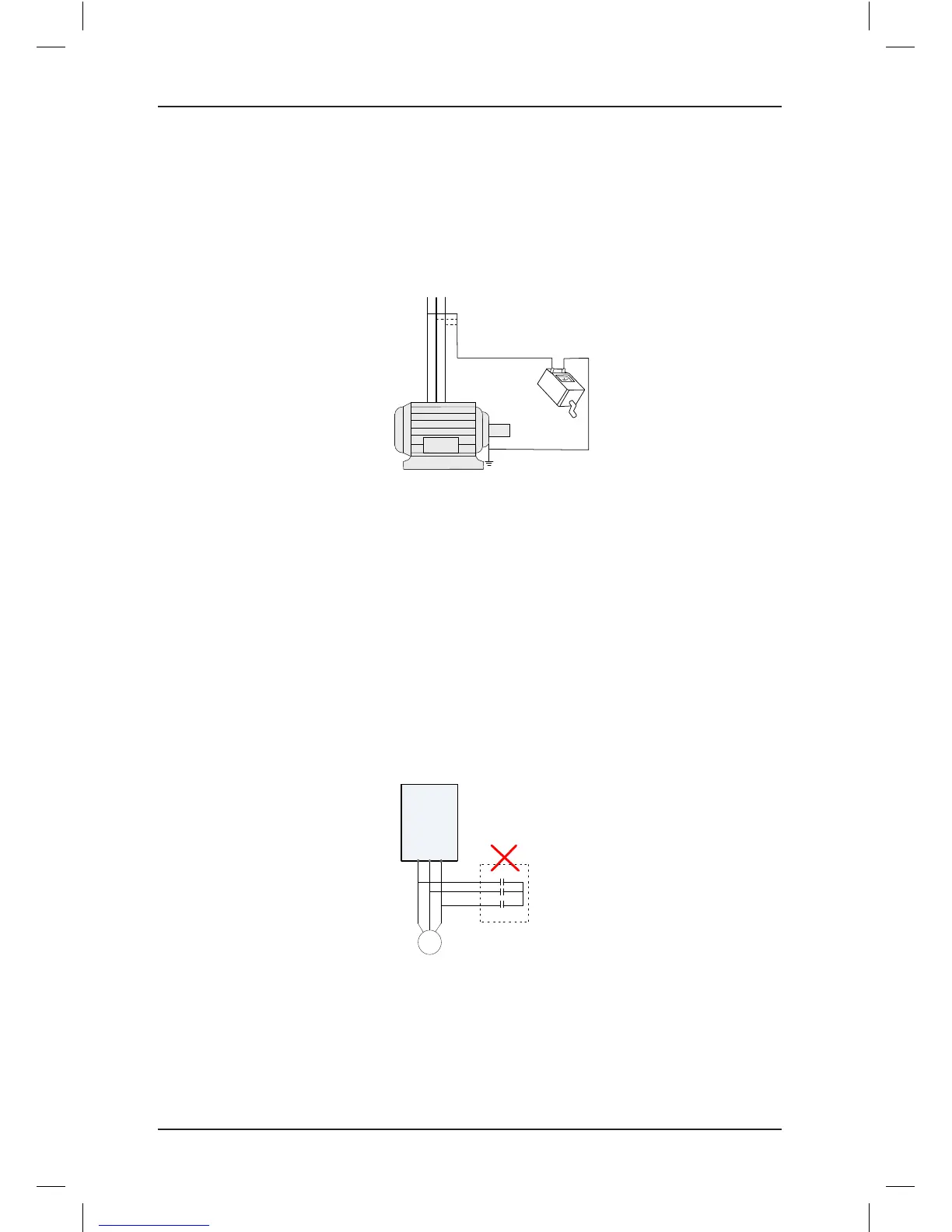

4. Thermal protection of motor

If the rated capacity of the motor selected does not match that of the controller, especially

when the rated power of the controller is greater than that of the motor, adjust the motor

protection parameters on the operation panel of the controller or install a thermal relay for

the motor circuit for protection.

5. Motor heat and noise

The output of the controller is pulse width modulation (PWM) wave with certain harmonic

wave, and therefore, the motor temperature rise, noise, and vibration are slightly greater

than those at running with the mains frequency.

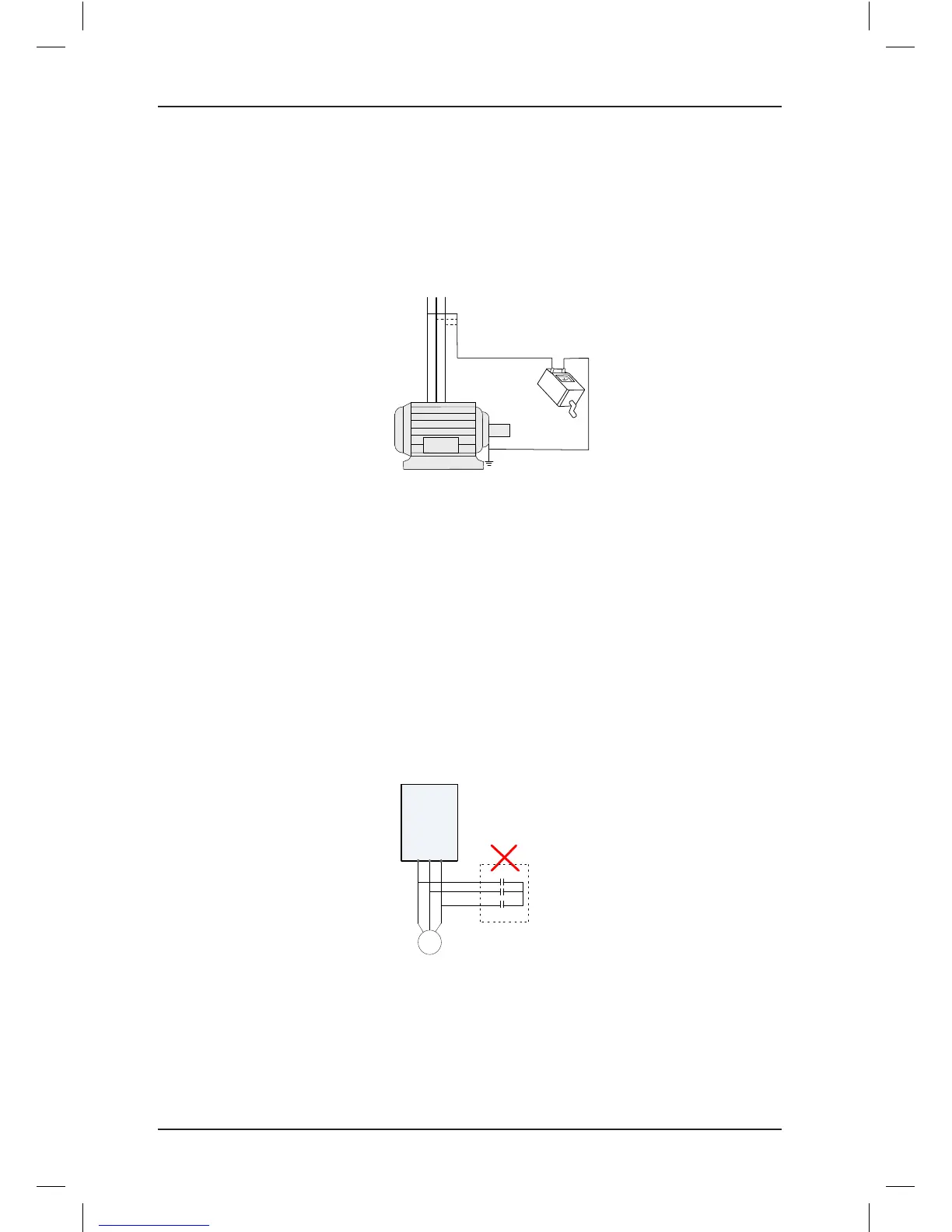

6. Voltage-sensitive device or capacitor on the output side of the controller

The controller outputs PWM waves, and therefore, do not install the capacitor for improving

power factor or lightning protection voltage-sensitive resistor on the output side of the

controller. Otherwise, the controller may suffer transient overcurrent or even be damaged.

7. Contactor on the input and output sides of the controller

When a contactor is installed between the input side of the controller and the power supply,

the controller must not be started or stopped by turning on or off the contactor.

If the controller has to be operated by the contactor, ensure that the time interval between

switching is at least one hour because frequent charge and discharge will shorten the

Loading...

Loading...