- 60 -

4. Check the grounding.

Check that the resistance between the following points and the ground is close to innity.

־ R, S, T and PE

־ U, V, W and PE

־ 24V and PE on the MCB

־ Motor U, V, W and PE

־ +, – bus terminals and PE

־ Safety circuit, door lock circuit, and inspection circuit terminals and PE

5. Check the grounding terminals of all elevator electrical components and the power supply

of the control cabinet.

5.1.2 Setting and Auto-tuning of Motor Parameters

The NICE1000

new

supports two major control modes, sensorless vector control (SVC)

and closed-loop vector control (CLVC). SVC is applicable to inspection speed running for

commissioning and fault judgment running during maintenance of the asynchronous motor.

CLVC is applicable to normal elevator running. In CLVC mode, good driving performance

and running efciency can be achieved in the prerequisite of correct motor parameters.

■

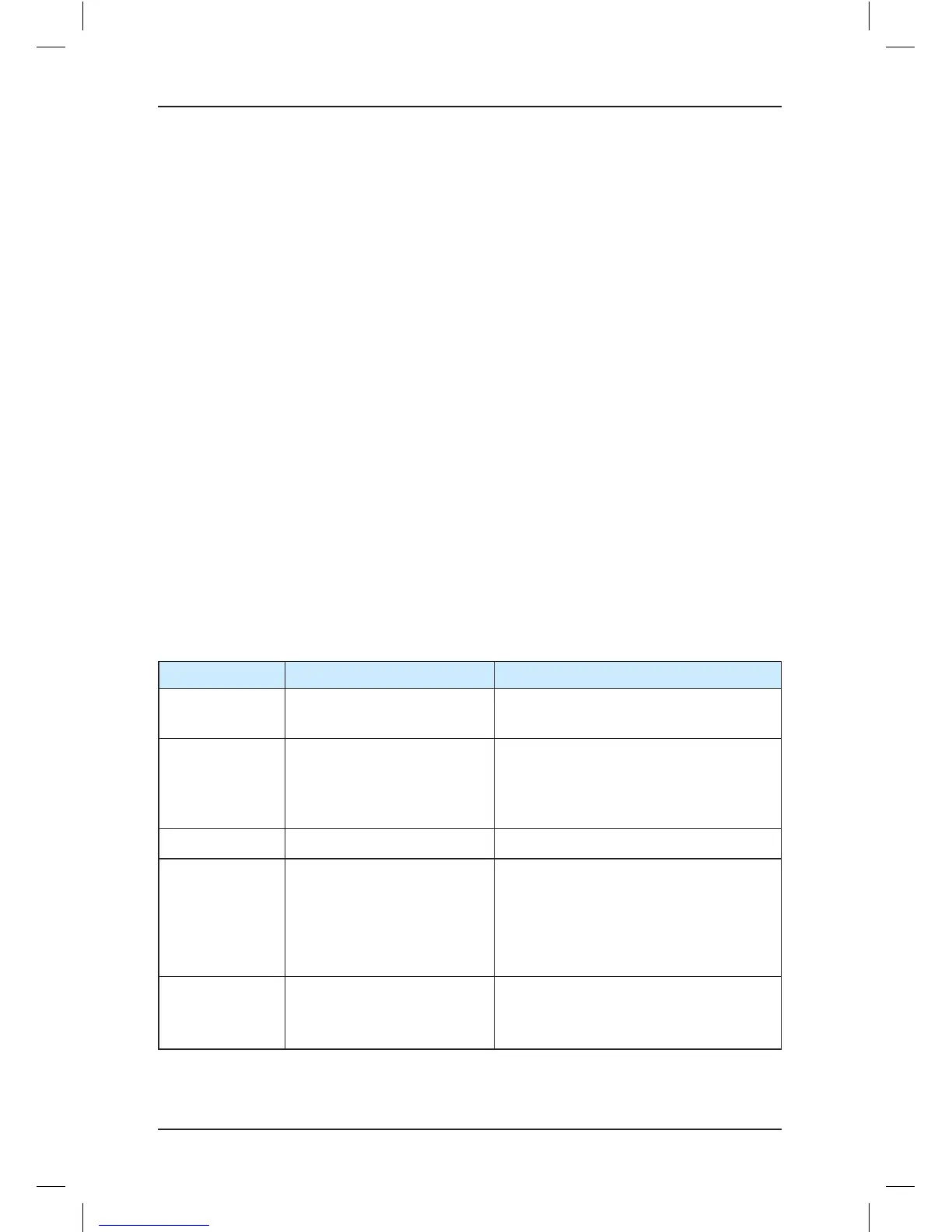

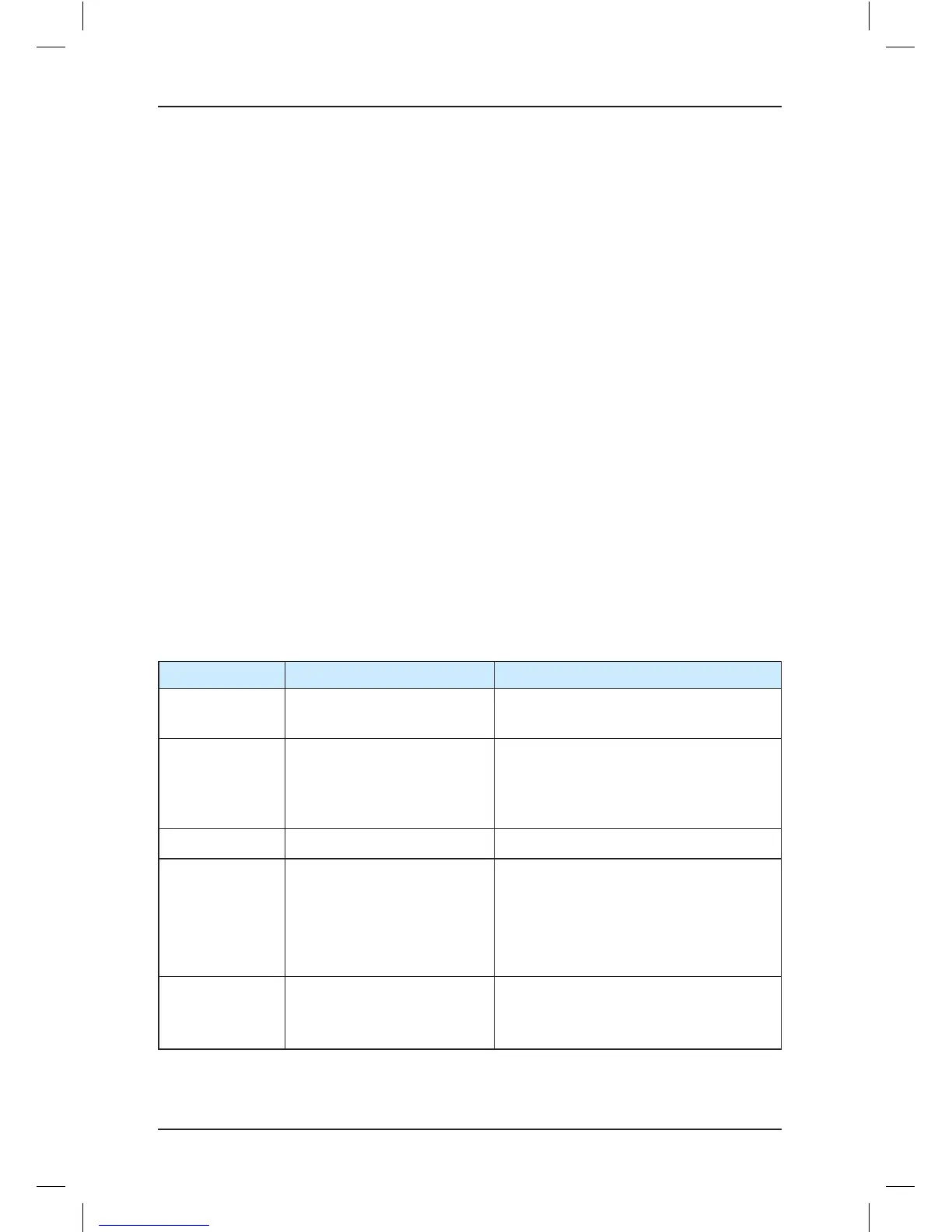

Motor Parameters to Be Set

The motor parameters that need to be set are listed in the following table.

Table 5-1 Motor parameters to be set

Function Code Parameter Name Description

F1-25 Motor type

0: Asynchronous motor

1: Synchronous motor

F1-00 Encoder type

0: SIN/COS encoder, absolute encoder

1: UVW encoder

2: AB incremental encoder (for

asynchronous motor)

F1-12 Encoder pulses per revolution 0–10000

F1-01 to F1-05

Rated motor power

Rated motor voltage

Rated motor current

Rated motor frequency

Rated motor rotational speed

These parameters are model dependent,

and you need to manually input them

according to the nameplate.

F0-00 Control mode

0: Sensorless vector control (SVC)

1: Closed-loop vector control (CLVC)

2: Voltage/Frequency (V/F) control

Loading...

Loading...