2 Basic repair procedures Chapter E: Basic repair procedures

132 Planmeca PlanMill 40 Technical manual

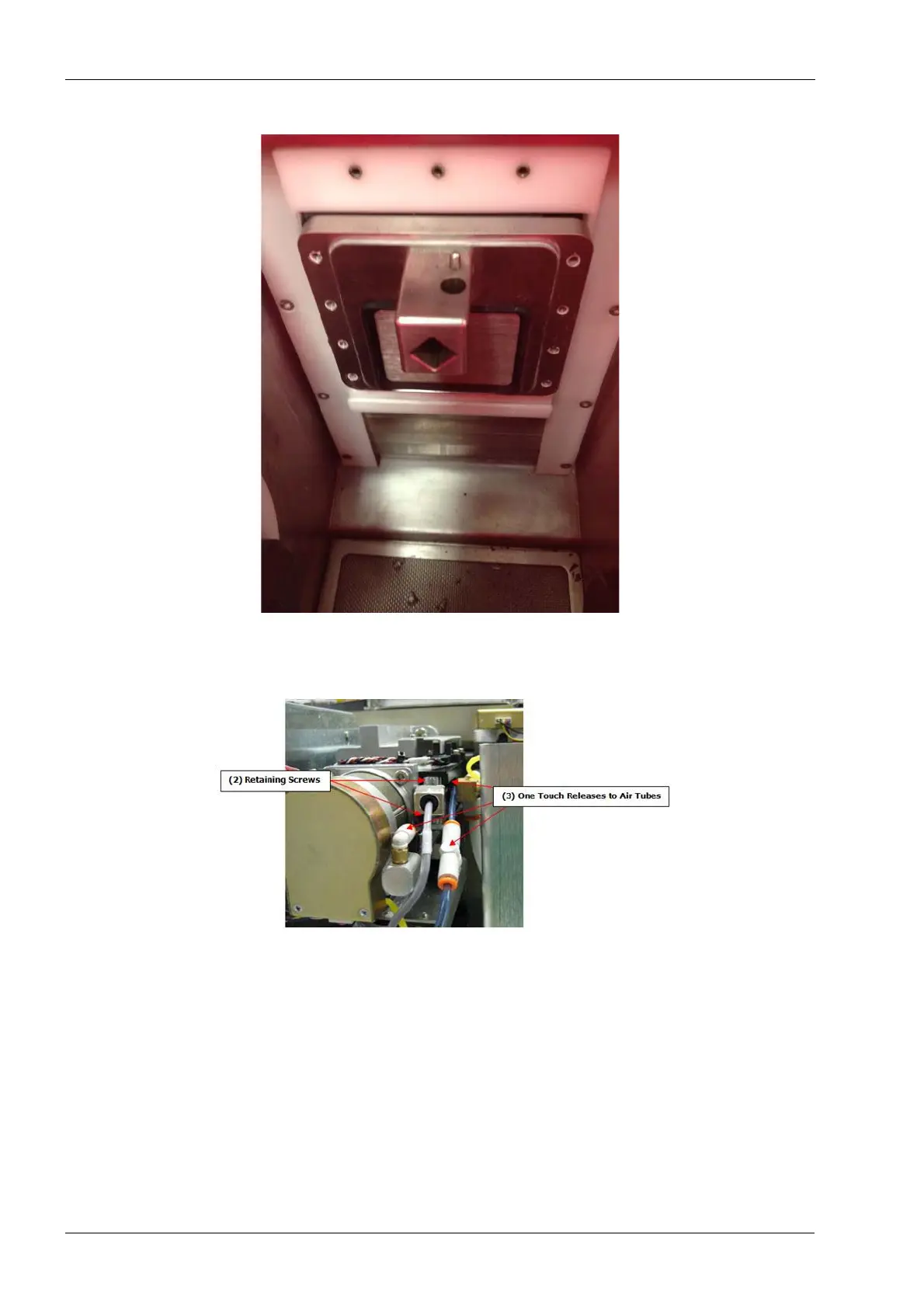

Figure 128: Bellows assembly removed

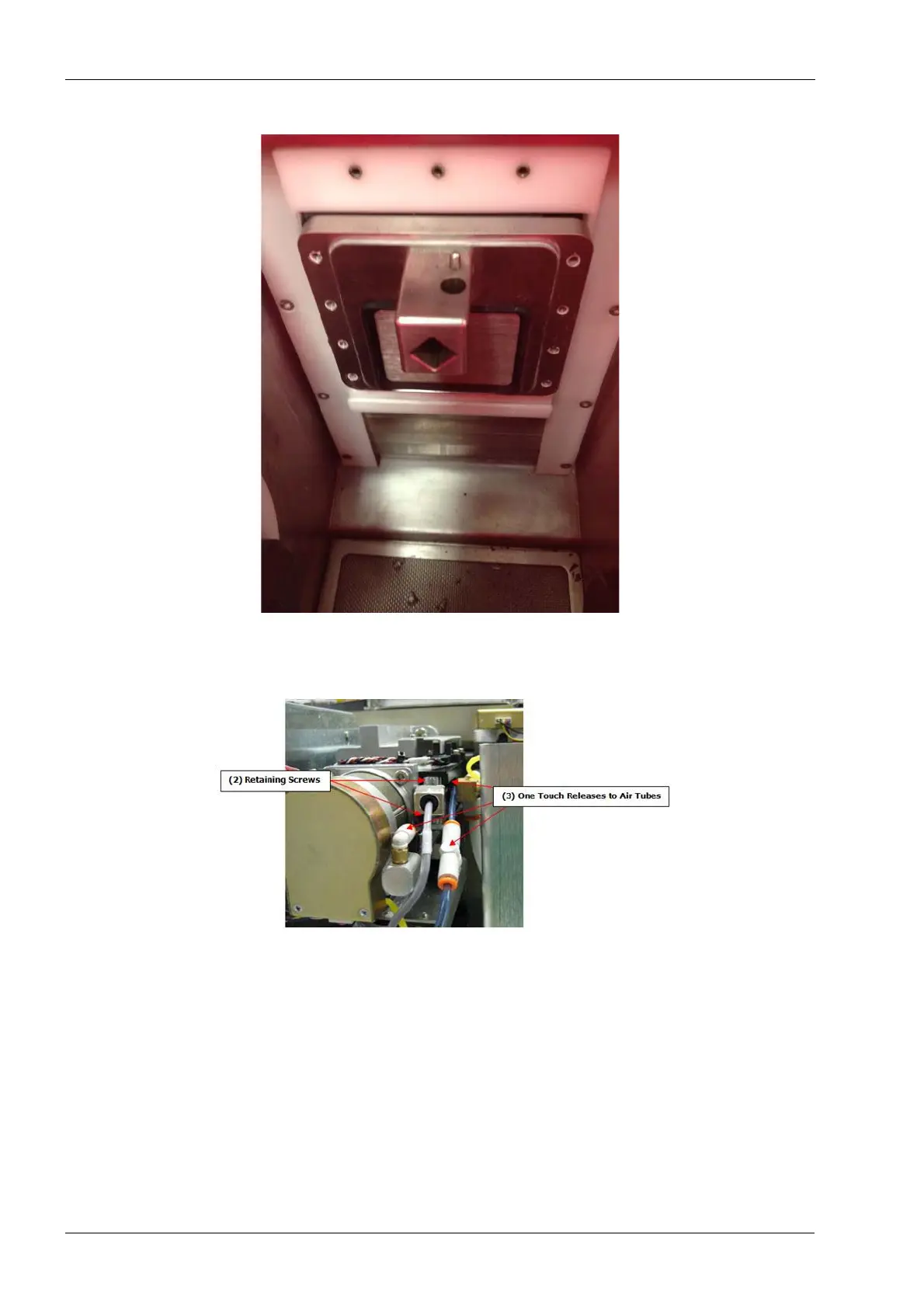

11. Use the small flat screwdriver to remove the (2) retaining screws and disconnect the

tool changer electrical connector from the rear of the tool changer assembly.

Figure 129: Disconnect cable and tubing

12. Disconnect the (3) air hoses from the tool changer, two from the air cylinder and one

from the purge orientation sensor.

Removing the front air cylinder tubing is possible using a small flat screw driver to depress

the one touch ring on the fitting to release the tubing.

13. Extend the Y-axis forward to allow access to the front mounting screws

Remember to never put pressure on the back face of the servo motor, this cover is thin

sheet metal and can bend, damaging the encoder.

Loading...

Loading...