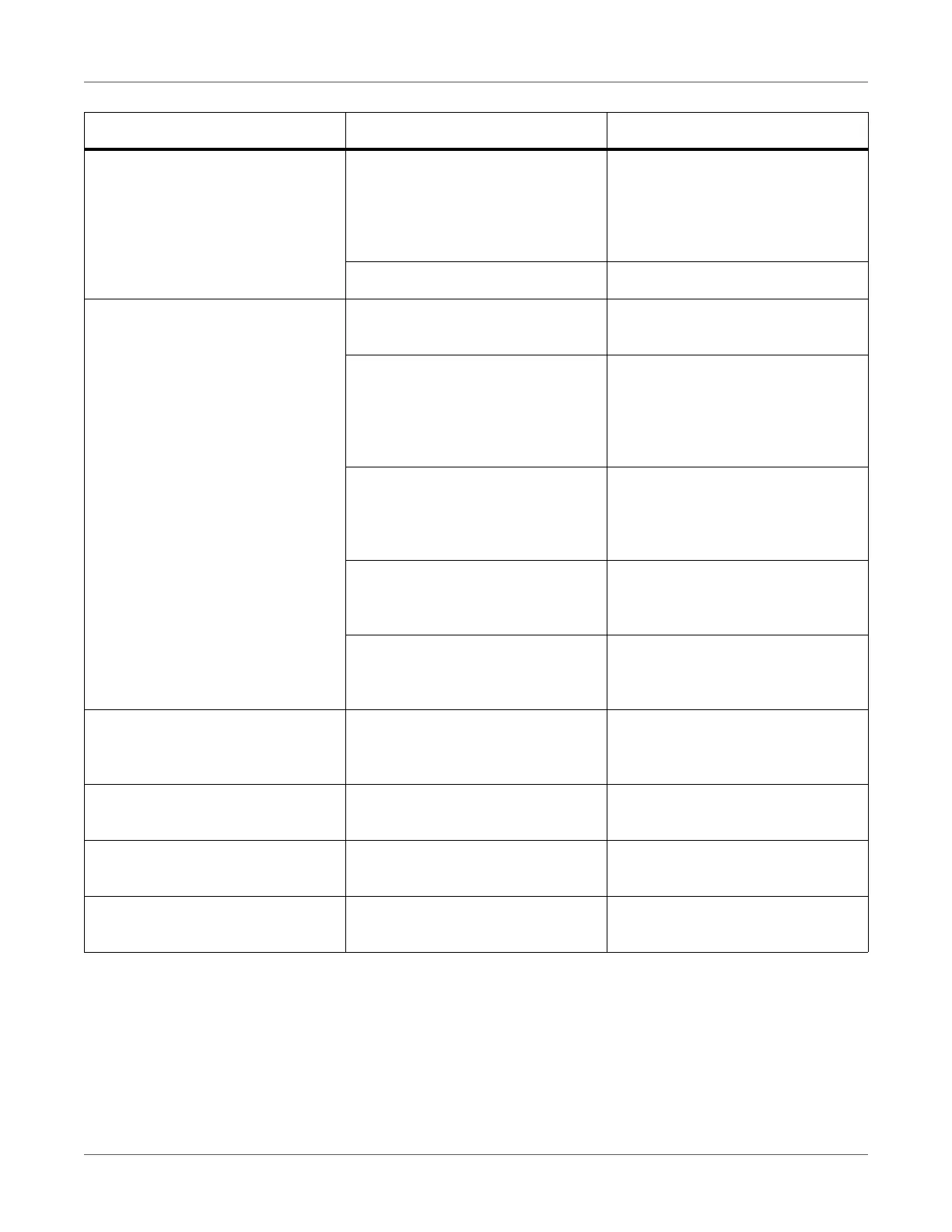

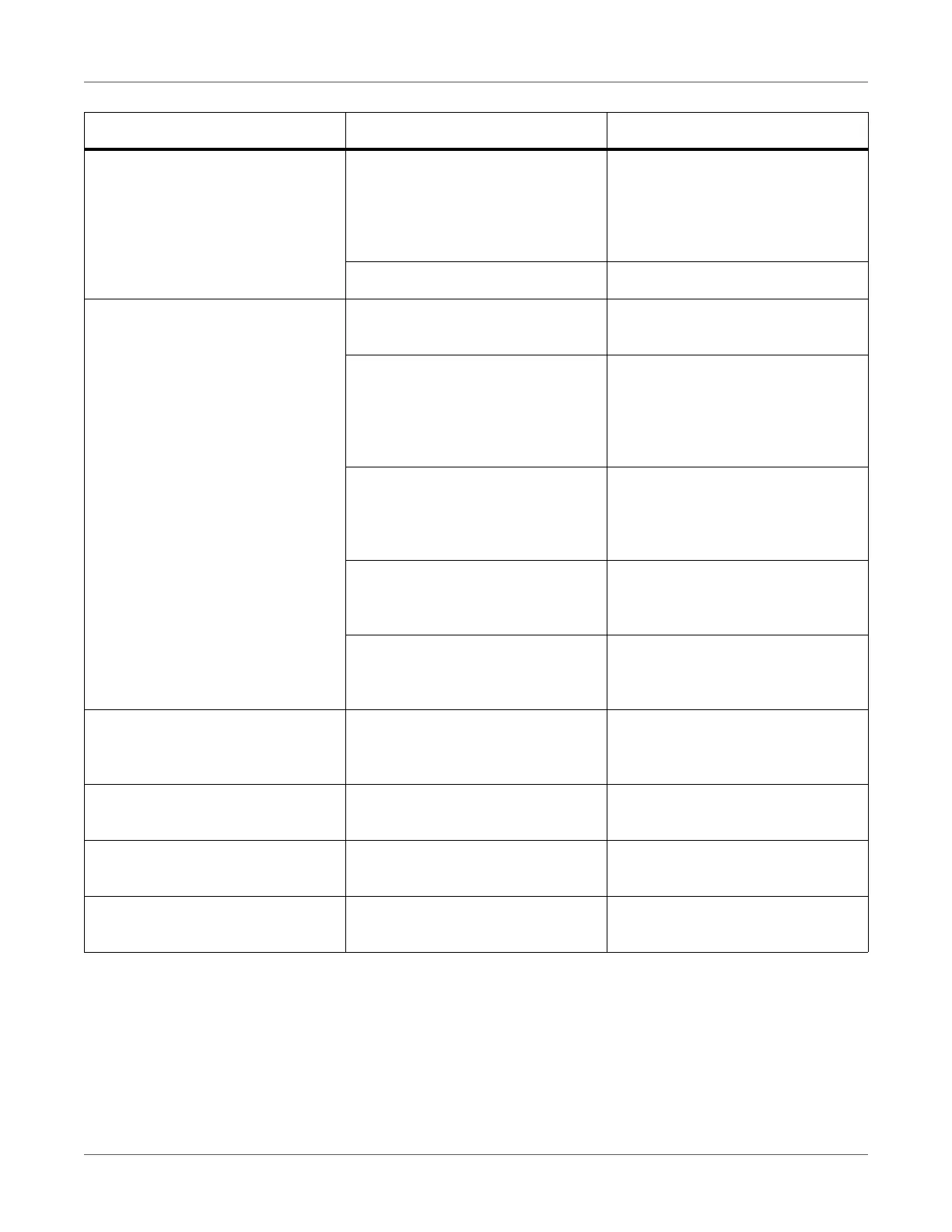

Troubleshooting

QL-300 User Guide 318

Paper winds around the roller of

the fuser and exit unit.

Type and thickness setting of paper

is inappropriate.

Correct Media Weight in the con-

trol panel to the appropriate value.

Or, change Media Weight to a

thicker value than the present

value.

Thin paper is used. Use thicker paper.

The space between labels is not

cut; the labels are cut.

The position of the cut is mis-

aligned.

Readjust the cutting position.

The leading edge of the label and

the black mark positions are not

aligned.

Labels cannot be used if the lead-

ing edge of the label and the black

mark positions do not align. Use

labels whose leading edges align

with the black mark.

The gap interval between labels is

different between each label.

Rolls of labels that have different

intervals between labels cannot be

used. Use rolls of labels that have

regular intervals.

The gap interval between labels is

not from 3 to 10 mm.

A gap between labels from 3 to 10

mm can be used. Do not use any

others.

The paper size specified in the

printer driver is different from the

paper size that is loaded.

Specify the correct paper size in

the printer driver.

Paper has stopped feeding. Last of the paper was detected

during warm up while paper was

feeding.

Replace the paper with a new roll

of paper.

Paper is not fed, even when the

FEED button is pressed.

Last of the paper was detected

while feeding paper.

Replace the paper with a new roll

of paper.

Paper is not unloaded, even when

the UNLOAD button is pressed.

Last of the paper was detected

while unloading paper.

Replace the paper with a new roll

of paper.

The rear edge of the paper is

skewed.

Paper is not set on the roll shaft. Replace the paper with a new roll

of paper.

Symptom Cause Troubleshooting

Loading...

Loading...