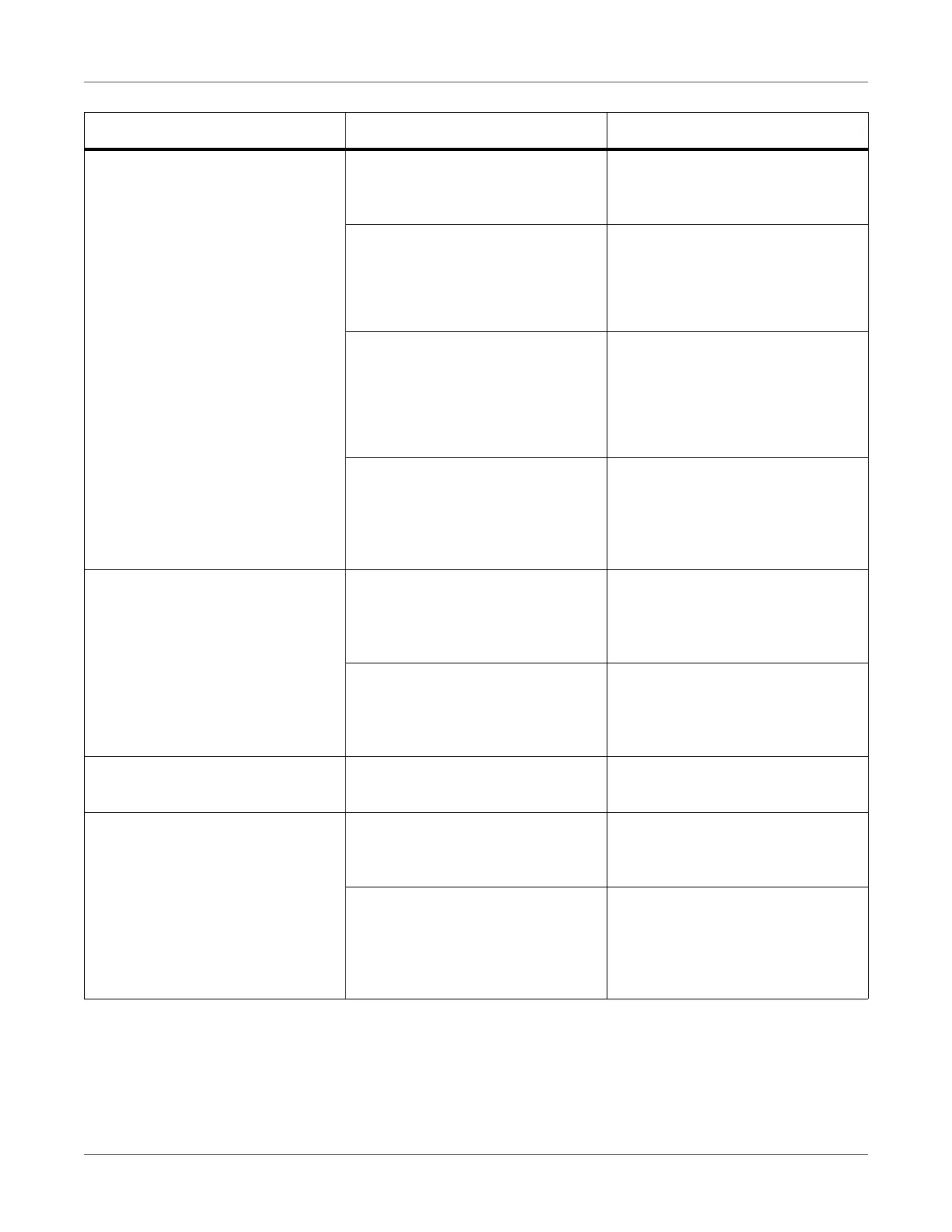

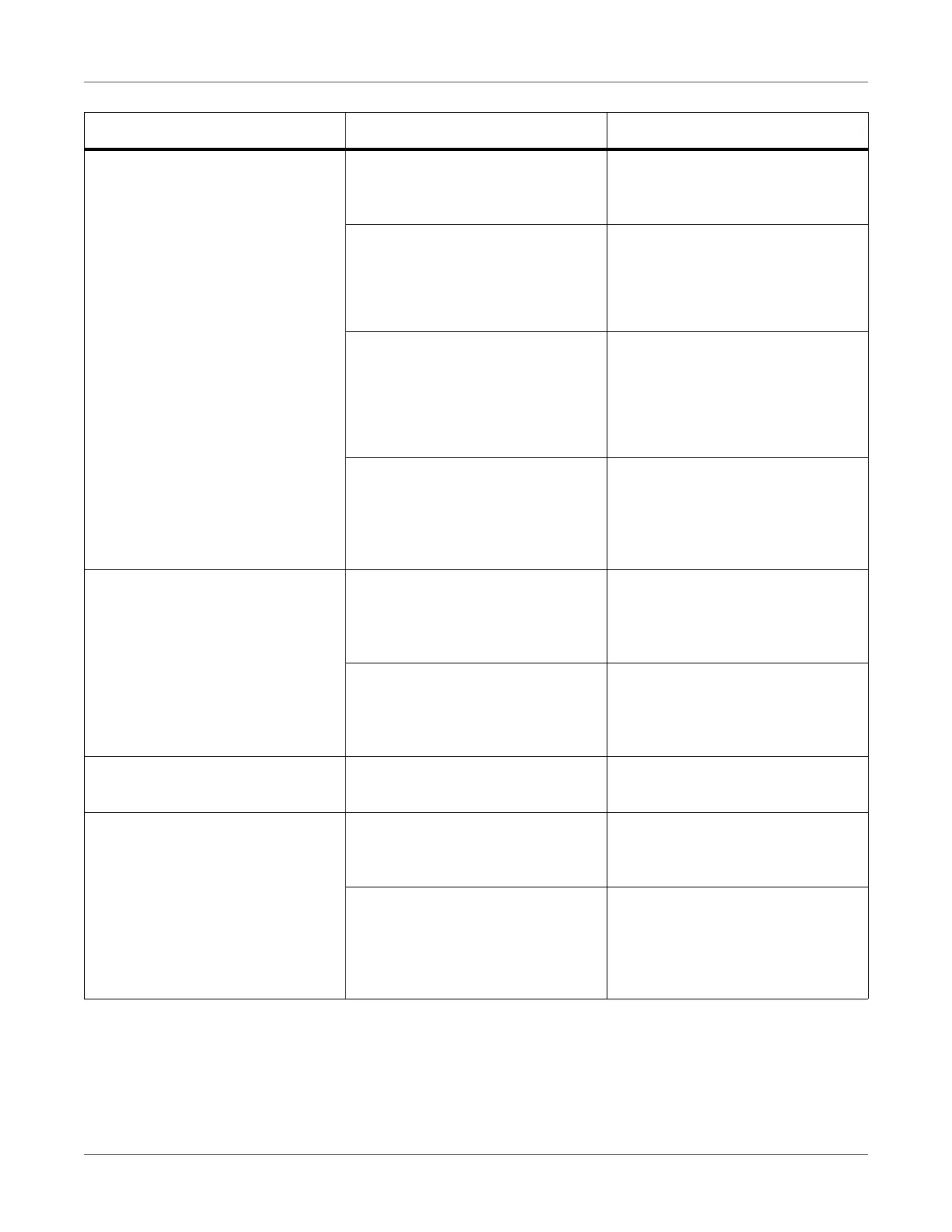

Troubleshooting

QL-300 User Guide 317

Paper jam occurs frequently. The positions of the machine and

the unwinder sensors do not

match.

Align the position of the sensor with

the paper.

Labels are missing from the roll of

paper that is being used.

Load a suitable roll of paper.

If the cause described on the left is

correct, there may be toner on the

fuser unit, so you should clean it.

Only when paper feed is started by

pressing the FEED button

Stiff continuous labels are being

used (or, die-cut labels that are lon-

ger than 600 mm).

Fold the media about 200 mm from

the leading edge of the media

(liner) to make a crease that forms

a valley in the printed face, and

then feed the paper.

The roll of paper is old so its color

or quality has changed.There are

large differences in the reflective-

ness of the black marks or the

transmittance of the liner.

Calibrate the sensor.

Paper is not fed. The paper settings for the printer

are different from the paper set-

tings in the printer driver.

Check the message on the display

screen, and if there is no problem,

press the OK button on the control

panel.

Glue has smeared on the liner. Do not use a liner on which glue is

smeared. It will not feed normally.

In the worst case, it could damage

the equipment.

Device is not restored even after

removing the jammed paper.

Open the top cover at once, and

the close it again.

Paper gets curled. Creases appear

on the paper.

Paper contains moisture or static

electricity.

Use paper that has been stored at

appropriate temperature and

humidity.

Thin paper is used. Correct Media Weight in the con-

trol panel to the appropriate value.

Or, change Media Weight to a

thicker value than the present

value.

Symptom Cause Troubleshooting

Loading...

Loading...