Section04ENGINE

Subsection 01 (593, 593 HO, 593 HO SDI AND 793 HO ENGINE TYPES)

A33C17A

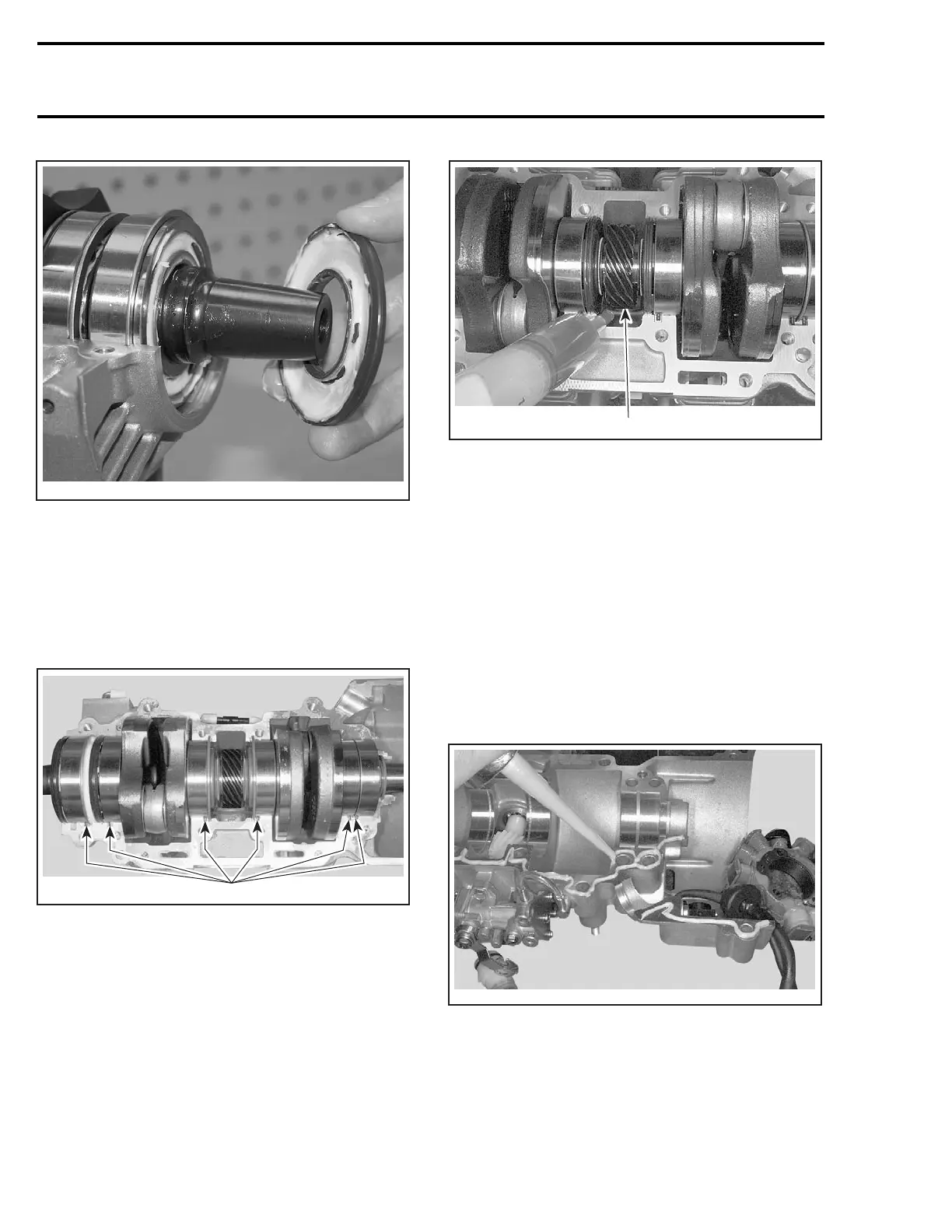

TYPICAL — FILL WITH GREASE AND SET IN PLACE

Apply 6 mL of grease to MAG side outer bearing.

NOTE: If replaced with new bearing, do not apply

grease as new bearings come with grease already

applied.

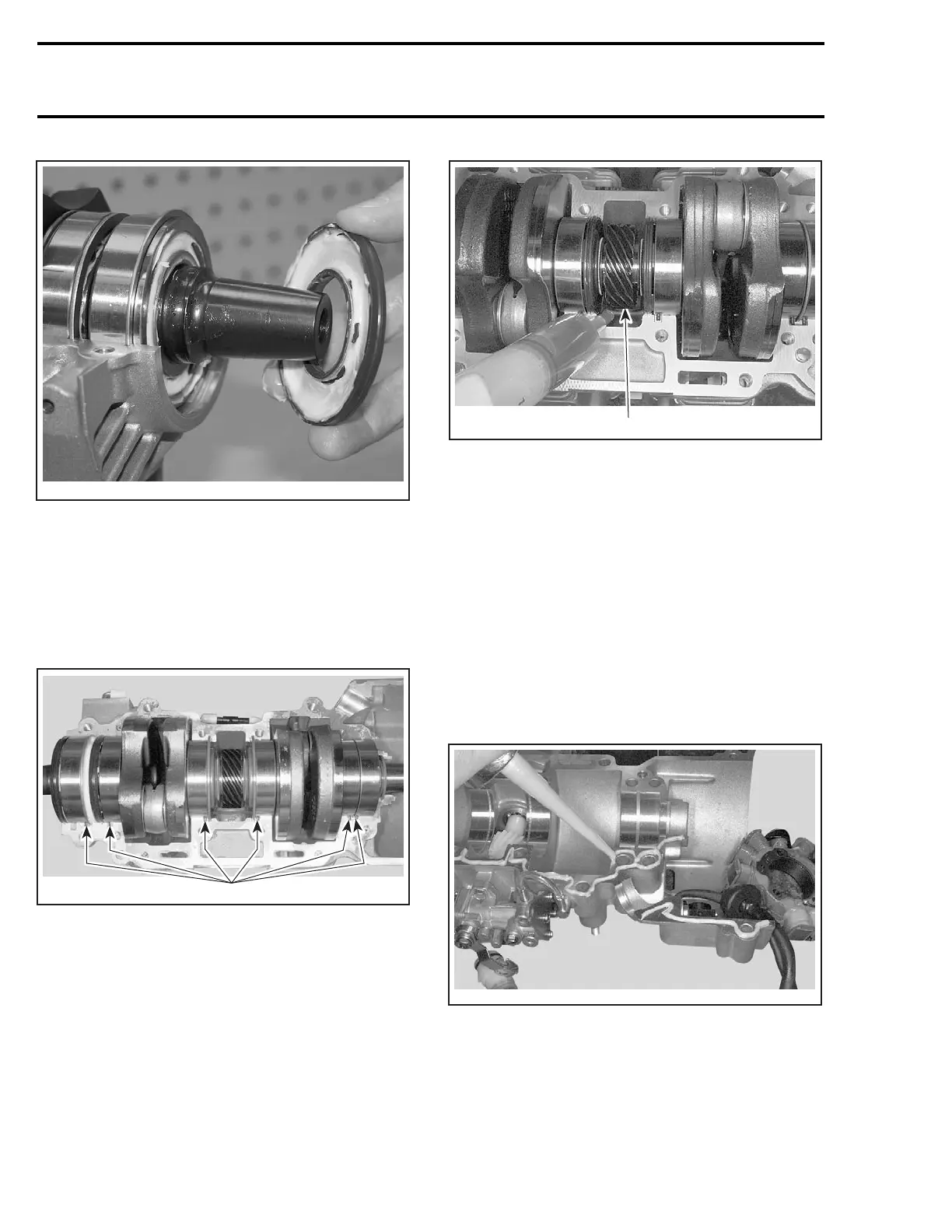

At crankshaft installation, position drive pins as il-

lustrated.

1

A32C1CA

TYPICAL

1. Position pins

Pour 50 mL (2 U.S. oz) of injection oil in the pan

under central gear to lubricate pump gearing as

per photo.

1

A32C0DA

1. Oil bath

Crankcase Assembly

IMPORTANT: The total assembly sequence, in-

cluding sealing compound spreading, screwing

and torquing of bolts according to the proper

sequence, must be performed within 10 minutes.

Do not wait between each bolt torquing. All bolts

mustbetorquedinarow.

Before screwing both parts of crankcase, seal it

with sealing compound (P/N 420 297 906). Make

sure surfaces are clean and degreased before ap-

plying sealing compound.

Spread a seam of 1.2 mm (1/16 in) maximum in

diameter on surface of lower crankcase half.

A32C0EA

As far as possible, sealing compound must be

applied in one run to avoid any risks of leakage

through the crankcase.

108 mmr2004-Rev

Loading...

Loading...