Section 06 TRANSMISSION

Subsection 02 (DRIVE PULLEY)

A16D2PB

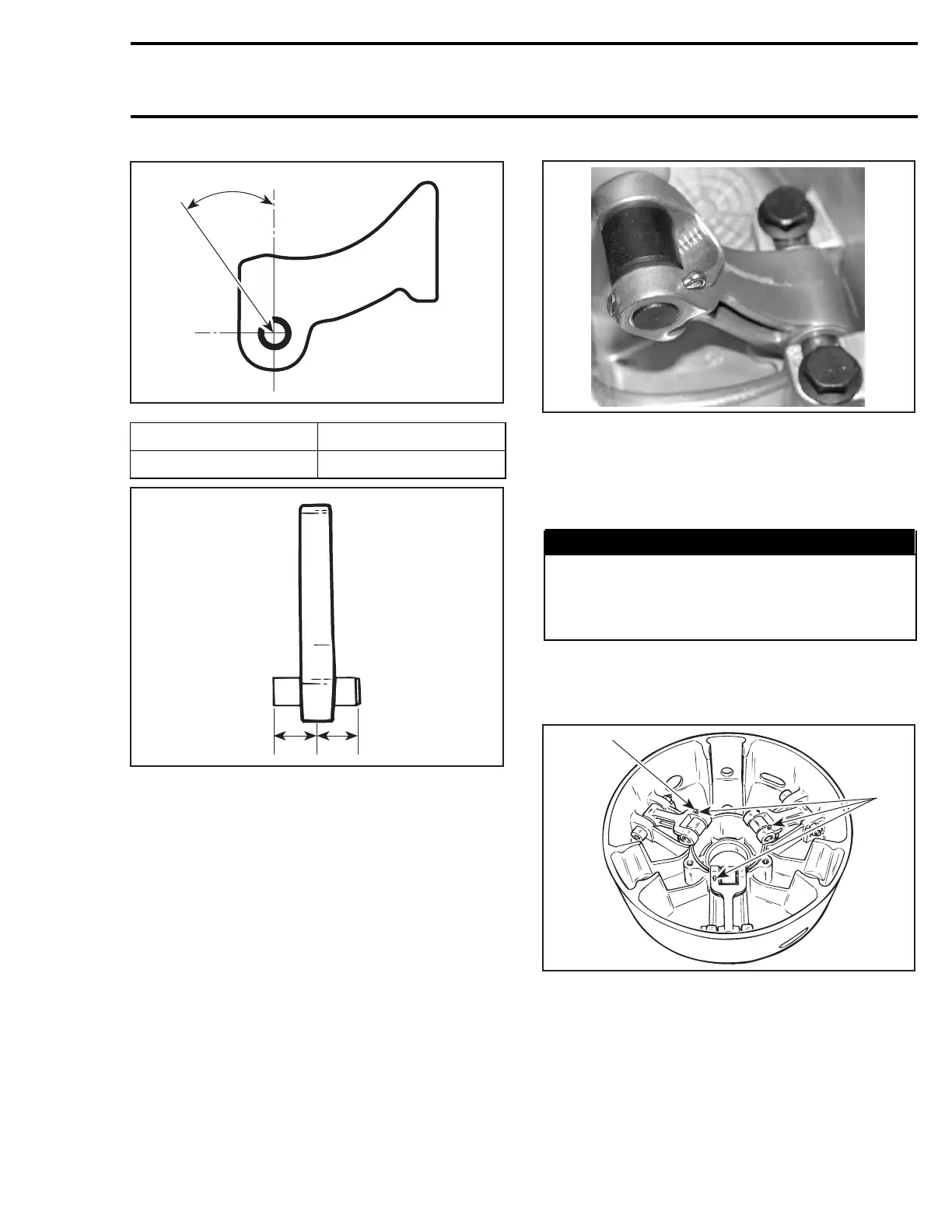

A

MODEL ANGLE (A)

With TRA III 45 ± 3°

A16D09A

11

1. Equal distance

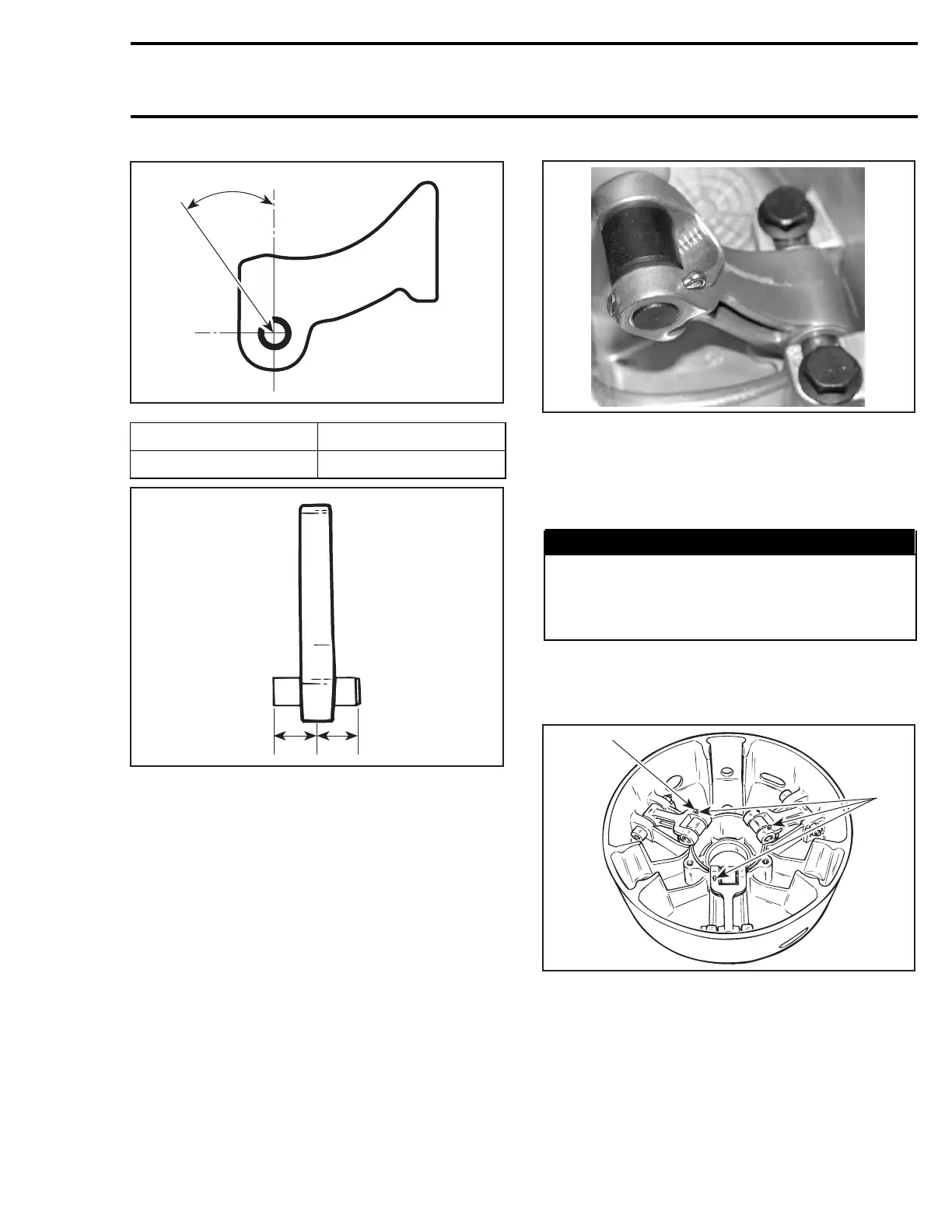

Torquescrewsto10N•m(89lbf•in).

9,11,13,14, Screw, Lever Ass’y,

Nut and Cotter Pin

NOTE: While installing lever assemblies make

sure that the curved sides of the levers are out-

wards as shown.

A32D1ZA

Always install lever assemblies so that cotter pins

are on the shown side. Besides install cotter pin

head on top when lever is sat at bottom of sliding

half. Bend cotter pin ends to sit perfectly against

lever.

WARNING

Whenever replacing centrifugal levers, al-

ways replace all 3 at the same time. Other-

wise, drive pulley misbalancing will occur

because of levers difference.

CAUTION: Lever assemblies must be installed

so that cotter pins are on the same side.

793 HO Engine Equipped Models Only

A16D0BA

1

2

TYPICAL

1. Head on top

2. All on the same side

mmr2004-Rev 221

Loading...

Loading...