Installing the Hydraulic Hoses and Tubes (O-Ring

Face Seal)

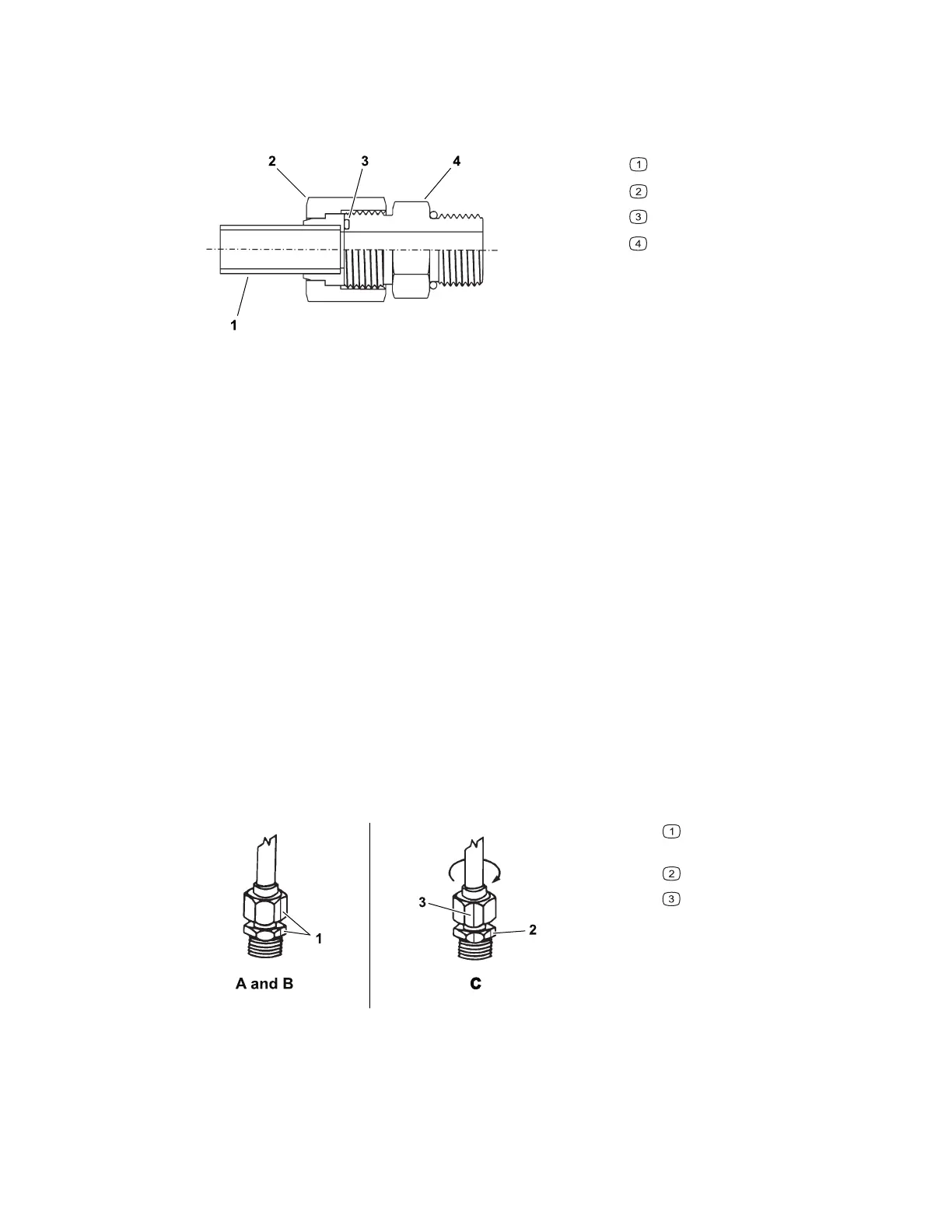

Figure 22

G212099

Tube or hose

Swivel nut

O-ring

Fitting body

1. Ensure that all threads, sealing surfaces of the hose, and fittings are free of burrs,

nicks, scratches, or unwanted material.

Note: The hydraulic hoses require 90 durometer Viton O-rings.

2. To help prevent a hydraulic leak, replace the face seal O-ring when a connection

is opened. Ensure the O-ring is installed and correctly seated in the groove of the

fitting. Lightly lubricate the O-ring with clean hydraulic fluid.

3. Align the hose/tube against the body of the fitting so that the flat face of the hose/

tube sleeve fully touches the O-ring in the fitting as shown.

4. Use your hand to thread the swivel nut onto the fitting. While you hold the hose/

tube in alignment with a wrench, use a torque wrench to tighten the swivel nut to

the recommended torque value within the specified range of torque values; refer

to the Hose/Tube Installation Torque Table, page 5–11. This procedure to tighten

the swivel nut requires a drive-adapter wrench (e.g., crowfoot wrench).

Note: It may be necessary to use a drive-adapter wrench (e.g., crowfoot wrench)

to install a hydraulic fitting; refer to Calculating the Torque Values When Using a

Drive-Adapter Wrench, page 2–5

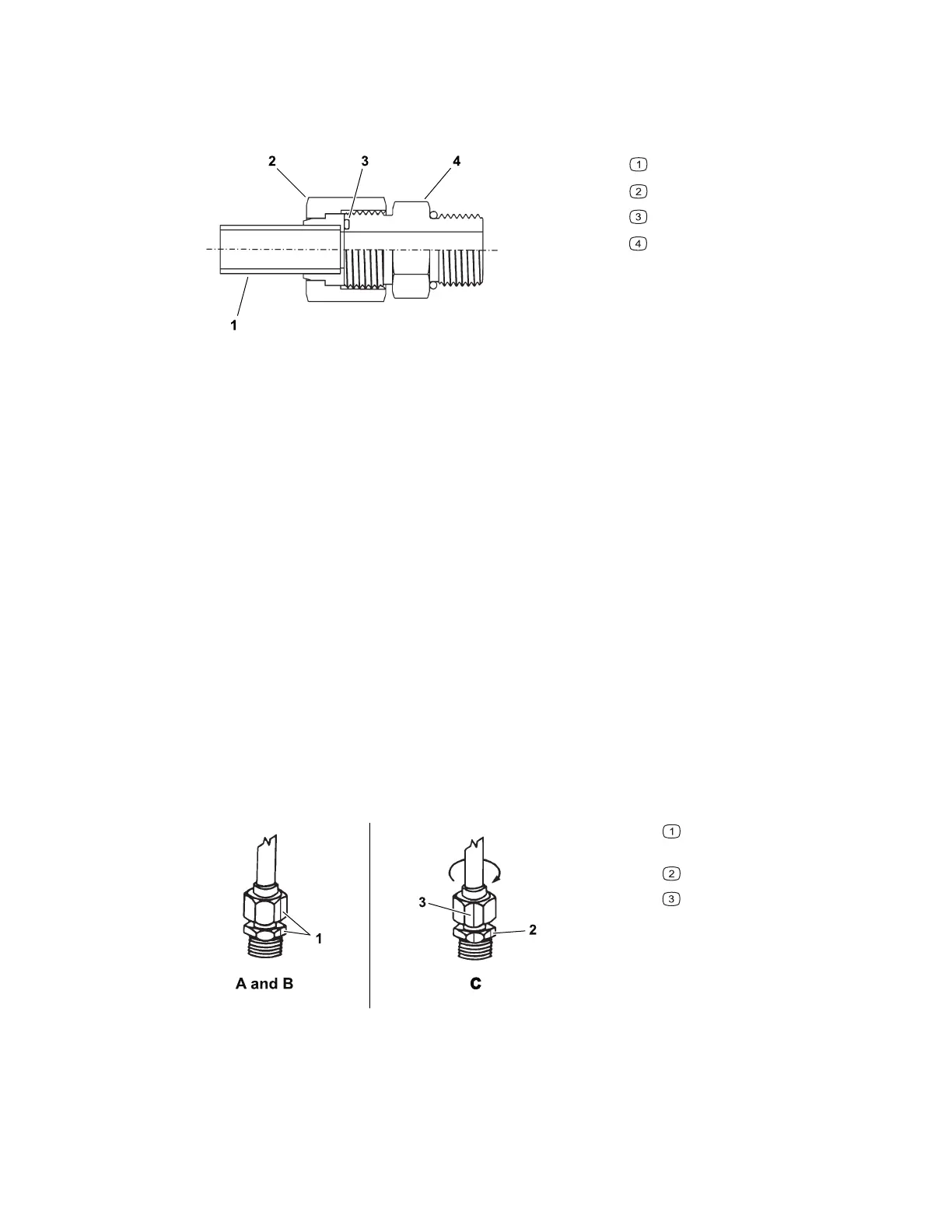

Figure 23

G212098

Mark swivel nut and

fitting body

Initial position

Final position

Hydraulic System: Hydraulic Hoses Page 5–10 4520P

09.40003Rev 00

Loading...

Loading...