General Precautions for Removing and Installing

Hydraulic System Components (continued)

3. Remove all caps and plugs from the hydraulic lines, hoses, fittings and

components before connecting them again.

4. Use proper tightening procedures when installing the hydraulic components and

tightening hoses and fittings; refer to Installing the Hydraulic Hoses and Tubes

(O-Ring Face Seal), page 5–10 Installing the Hydraulic Fittings (SAE Straight

Thread O-Ring Fittings), page 5–12

Changing the Hydraulic Fluid

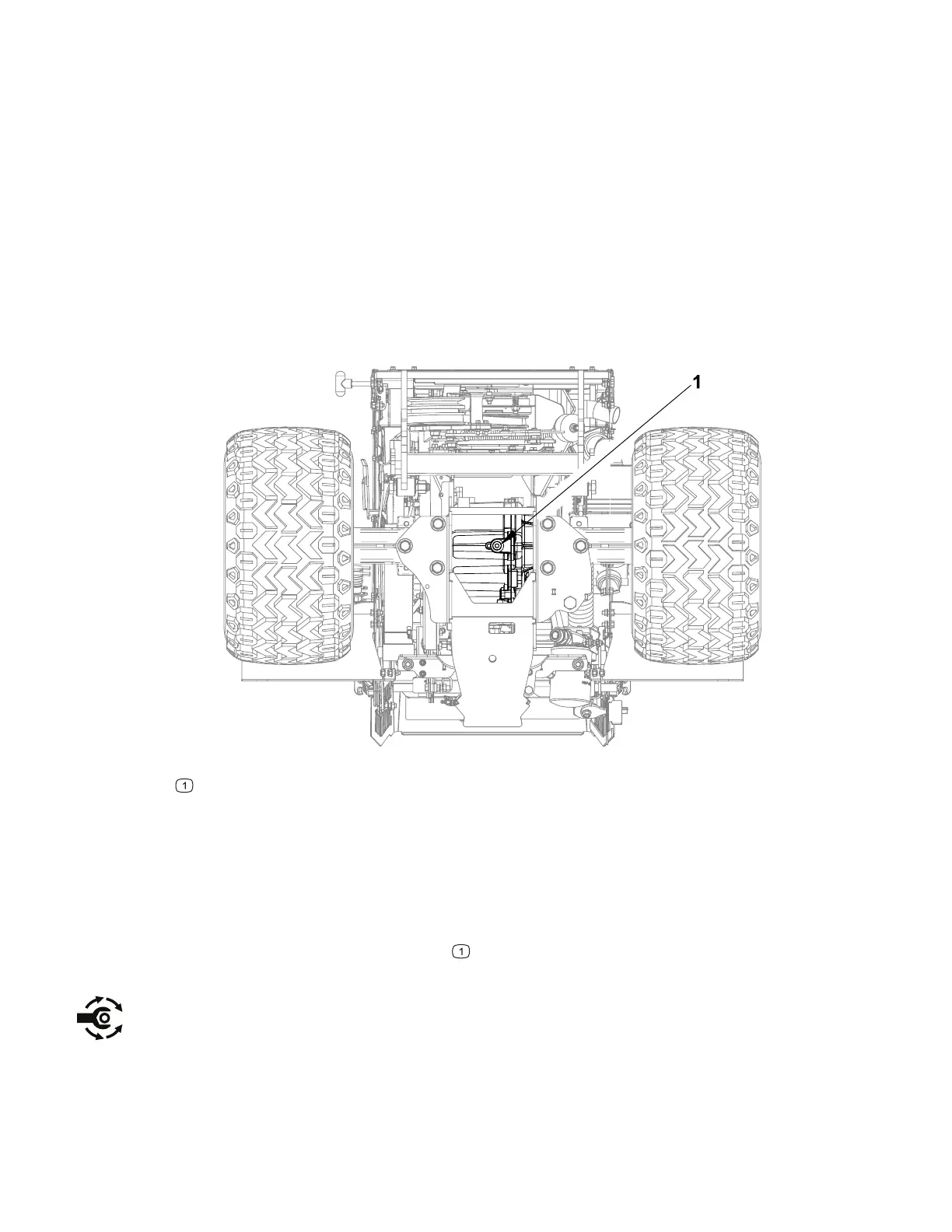

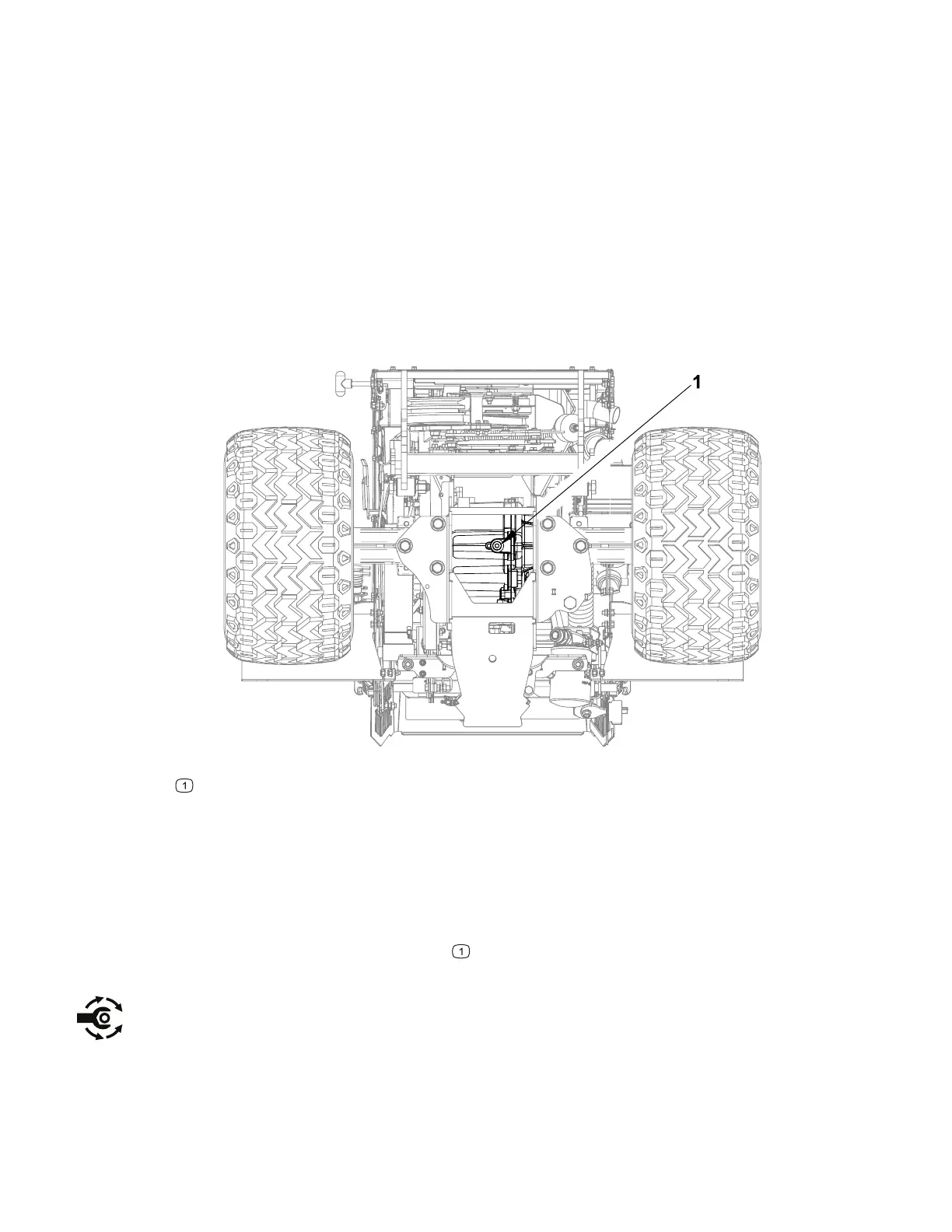

Figure 29

G438986

Drain plug

1. Remove any attachments from the machine.

2. Park the machine on a level surface, engage the parking brake, and remove the

key from the ignition. Ensure that the steering is straight ahead, fully raise the

front hitch, fully lower the three point hitch (if equipped).

3. Place a drain pan (minimum 13.5 liters / 14 quarts) under the front transaxle.

4. Locate and remove the drain plug

from the front transaxle. Loosen the cap on

the hydraulic oil tank to allow the system to vent.

5. Replace the O-ring and install the drain plug 37 Nm (27 ft-lb).

6. Add hydraulic oil as specified in the Operator’s Manual to the hydraulic oil tank

until the oil level in the plastic site tube is within the proper range indicated by the

oil level decal.

Hydraulic System: Service and Repairs Page 5–20 4520P

09.40003Rev 00

Loading...

Loading...