4.7 Auto-Tuning

u

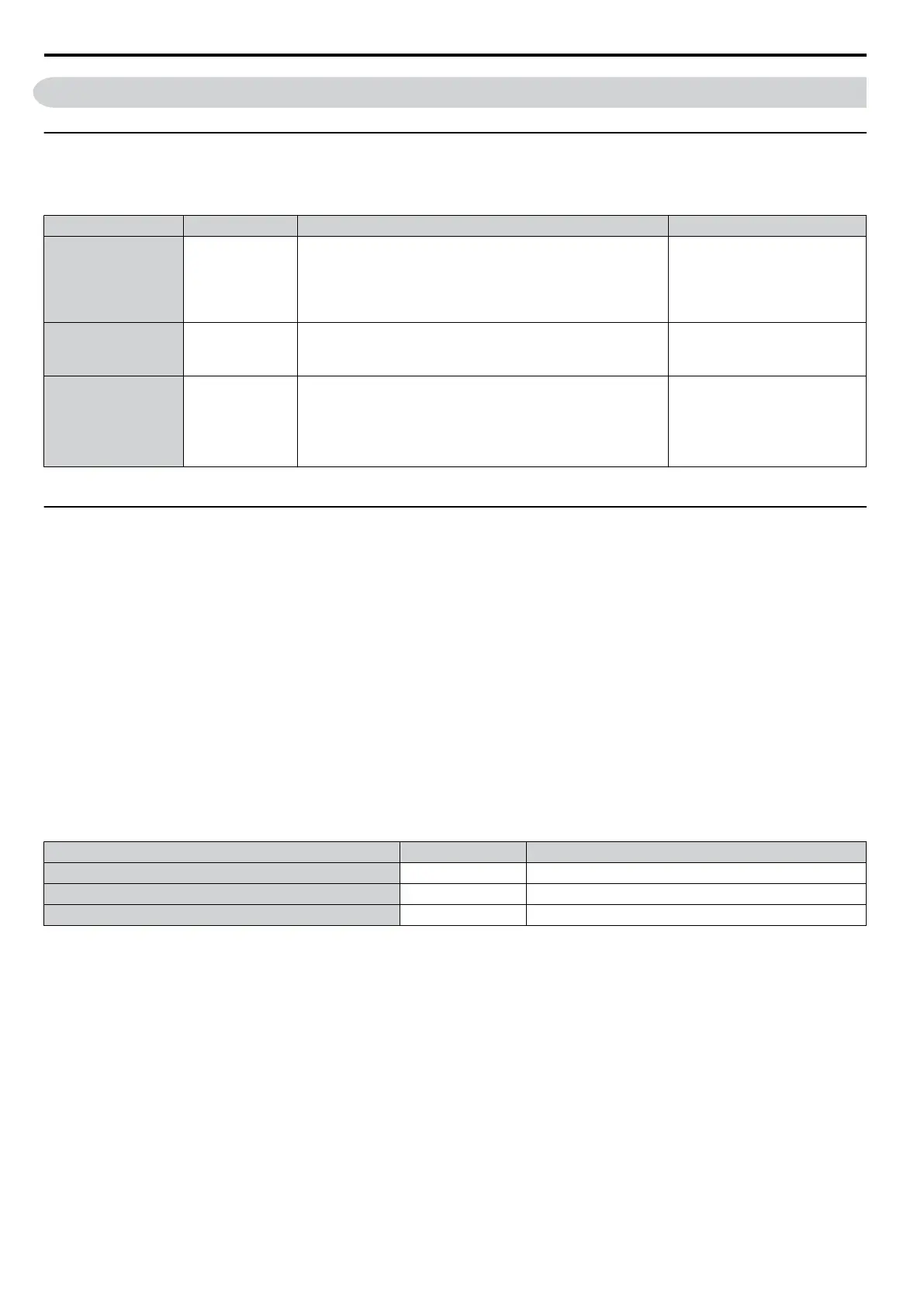

Types of Auto-Tuning

There are three types of Auto-Tuning. Select the best type of Auto-Tuning for the application. Refer to Auto-Tuning

Procedure on page 101.

Type Setting Application Conditions and Benefits Control Mode

Rotational

Auto-Tuning

for V/f Control

T1-01 = 3

• Assumes the motor can rotate during the Auto-Tuning process

• Improves torque compensation, slip compensation, energy

savings, and Speed Search performance

• Should be performed when Speed Estimation Type Speed

Search or Energy Saving is used in V/f Control

V/f Control

Rotational Auto-

Tuning

for OLV Control

T1-01 = 0

• Assumes the motor can rotate during the Auto-Tuning process

• Achieves high-performance motor control and should be

performed whenever Open Loop Vector Control is used

Open Loop Vector Control

Stationary Auto-

Tuning

for Line-to-Line

Resistance (V/f and

OLV Control)

T1-01 = 2

For use when:

• The motor cable exceeds 50 m

• The motor cable length has been modified after Auto-Tuning

has been previously performed

• When motor capacity and drive capacity differ

V/f Control, Open Loop Vector

Control

Note: Auto-Tuning cannot be performed on permanent magnet motors (IPM, SPM, etc.).

u

Before Auto-Tuning the Drive

Check the items below before Auto-Tuning the drive.

n

Basic Auto-Tuning Preparations

•

Auto-Tuning automatically determines the electrical characteristics of the motor. This is fundamentally different from

other types of Auto-Tuning features used in servo systems.

• Auto-Tuning requires the user to input data from the motor nameplate. Make sure the information written on the

nameplate is available before Auto-Tuning the drive.

• For best performance, be sure the drive input supply voltage equals or exceeds the motor rated voltage.

Note: Performance can be enhanced by using a motor with a base voltage that is 20 V (40 V for 400 V class models) lower than the input

supply voltage. This may be

of special importance when operating the motor above 90% of base speed, where high torque precision is

required.

• Auto-Tuning is not possible with permanent magnet motors.

• To cancel Auto-Tuning, press the STOP key on the LED operator.

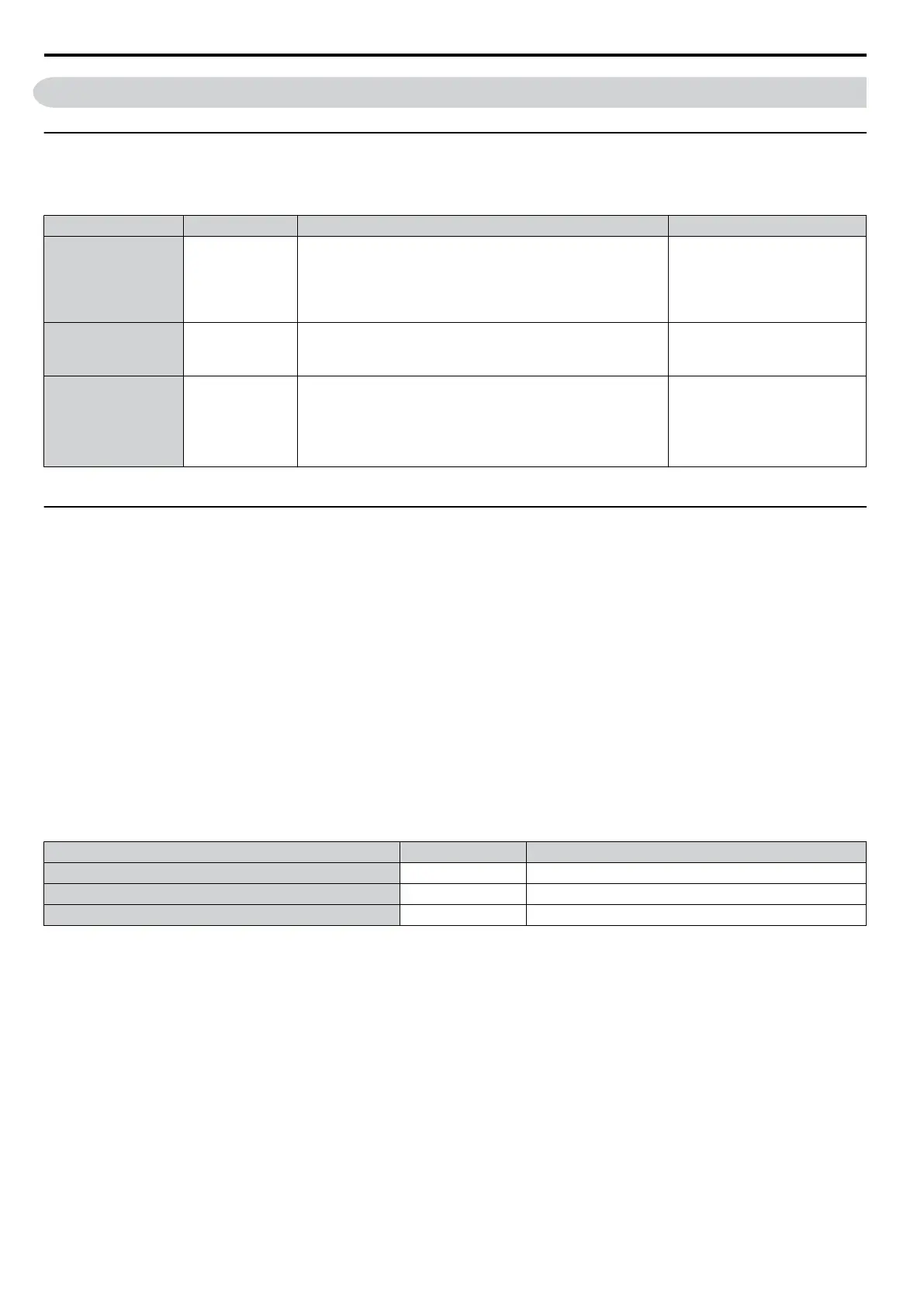

• Table 4.21 describes digital input and output terminal status during Auto-Tuning.

Table 4.21 Digital Input and Output Operation During Auto-Tuning

Auto-Tuning Type Digital Input Digital Output

Rotational Auto-Tuning for V/f Control Not available Functions the same as during normal operation

Rotational Auto-Tuning for OLV Control Not available Functions the same as during normal operation

Stationary Auto-Tuning for Line-to-Line Resistance Not available Maintains the status at the start of Auto-Tuning

WARNING! Sudden

Movement

Hazard.

Do

not

release

the

mechanical

brake during stationary Auto-Tuning. Inadvertent brake release

may cause damage to equipment or injury to personnel. Ensure that the mechanical brake release circuit is not controlled by the drive

multi-function digital outputs.

Note: It is recommended that Rotational Auto-Tuning is performed with the load disconnected. Failure to comply could result in improper

drive operation. If Rotational Auto-Tuning is performed for a motor coupled to a load, the motor constants will be inaccurate and the

motor may exhibit abnormal operation. Disconnect or decouple the motor from the load.

n

Notes on Rotational Auto-Tuning

• For optimal performance, Auto-Tuning should only be done with the motor uncoupled from the load for applications

requiring high performance over a wide speed range.

• If motor and load can not be uncoupled, the load should be lower than 30% of the rated load. Performing Rotational

Auto-Tuning with a higher load will set motor parameters incorrectly, and can cause irregular motor rotation.

• Ensure the motor-mounted brake is fully released if installed.

• Connected machinery should be allowed to rotate the motor.

4.7 Auto-Tuning

100

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

Loading...

Loading...