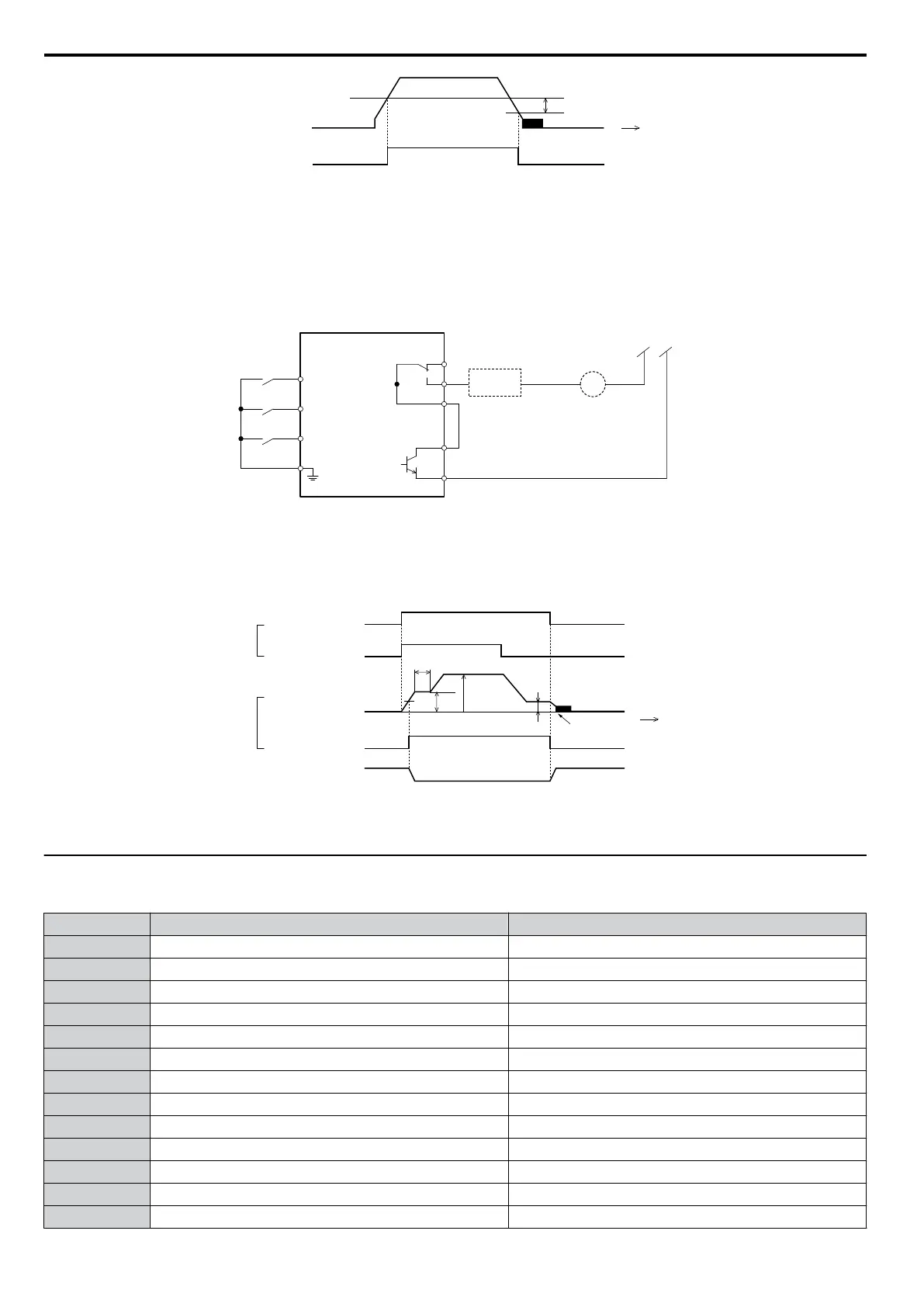

L4-02

L4-01

OFF

ON

time

output

frequency

Frequency

Dectection 2

Figure 4.10 Frequency Detection 2

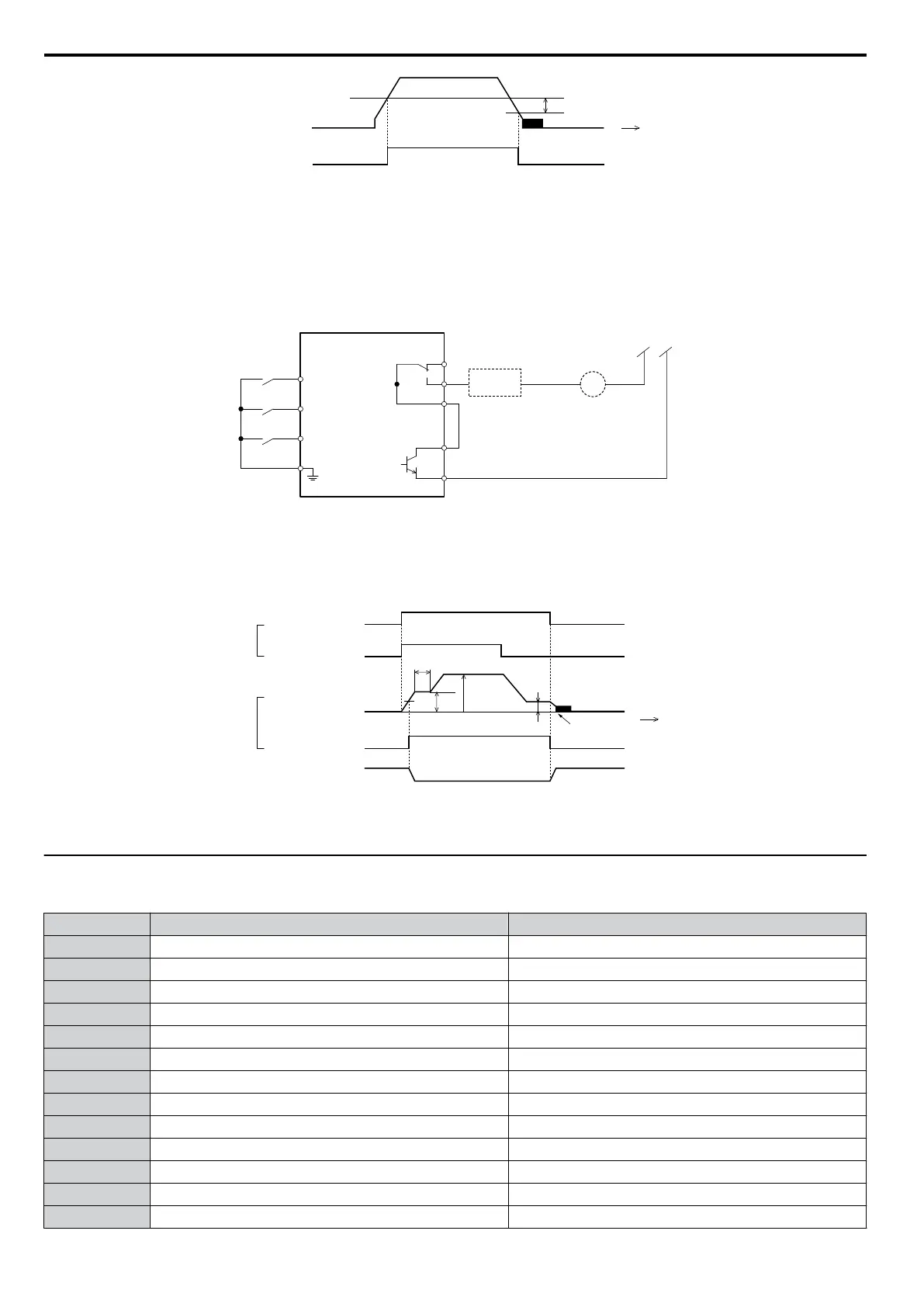

The braking sequence should be designed as follows:

• A normally open signal (N.O.) should be used to control the brake so that it is released when terminal P2-PC closes.

• When a fault signal is output, the brake should close.

Note: The drawing below shows a control wiring example for the crane application preset:

Safety

Circuit

BR

Drive

(Forward)

24 V

Frequency Detect 2

UP

DOWN

High speed

Low speed

(Reverse)

S2

(Multi-step speed 2)

MA

MB

MC

P2

PC

S6

SC

Fault Contact

Holding brake

auxilary relay coil

S1

Figure 4.11 Brake Control Wiring

• When changing the speed using an analog signal, make sure that the source of the frequency reference is assigned to the

control circuit terminals (b1-01 = 1).

• A sequence to open and close the holding brake appears in the diagram below.

Time

UP

S1-SC

S6-SC

OFF

OFF

d1-03

d1-01 (Enabled when b1-01 = 0)

L4-01

b2-01

OFF

DC Injection braking

ON

ON

ON

P2-PC

Holding brake

Fast/Slow

Output frequency

0

Frequency Detection 2

(H2-03

=

05)

Closed Closed

Open

b6-02

b6-01

Input

Output

Figure 4.12 Holding Brake Time Chart

u

Setting 7: Traveling Application

Table 4.17 Traveling: Parameters and Settings

No. Parameter Name Default Setting

A1-02 Control Method Selection 0: V/f Control

b1-01 Frequency Reference Selection 1 0: Operator

C1-01 Acceleration Time 1 3.0 s

C1-02 Deceleration Time 1 3.0 s

C6-01 Drive Duty Selection 0: Heavy Duty

C6-02 Carrier Frequency Selection 2: 5 kHz

d1-01 Frequency Reference 1 6.0 Hz

d1-02 Frequency Reference 2 30.0 Hz

d1-03 Frequency Reference 3 60.0 Hz

H1-05 Multi-Function Digital Input Terminal S5 Function 3: Multi-Step Speed 1

H1-06 Multi-Function Digital Input Terminal S6 Function 4: Multi-Step Speed 2

H2-02 Terminals P1 Function Selection 37: During frequency output

L3-04 Stall Prevention Selection during Deceleration 0: Disabled

4.6 Application Selection

98

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

Loading...

Loading...