3.6 Main Circuit Wiring

This section describes the functions, specifications, and procedures required to safely and properly wire the main circuit

of the drive.

NOTICE: Do not solder the ends of wire connections to the drive. Soldered wiring connections can loosen over time. Improper wiring

practices could result in drive malfunction due to loose terminal connections.

u

Main Circuit Terminal Functions

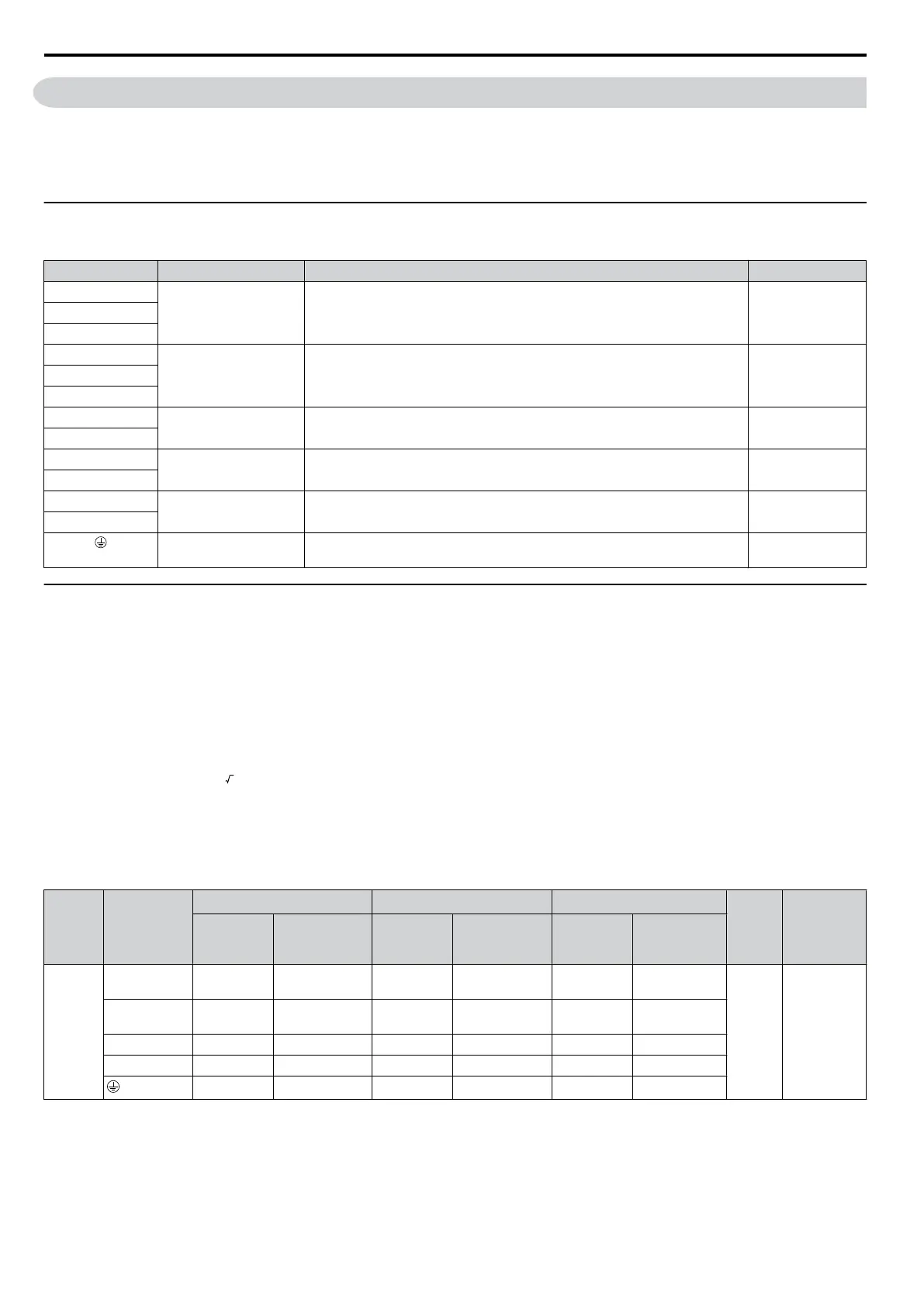

Table 3.1 Main Circuit Terminal Functions

Terminal Type Function Reference

R/L1

Main circuit power

supply input

Connects line power to the drive.

Drives with single-phase 200 V input power use terminals R/L1 and S/L2 only.

T/L3 must not be used.

51S/L2

T/L3

U/T1

Drive output Connects to the motor. 60V/T2

W/T3

B1

Braking resistor Available for connecting a braking resistor or the braking resistor unit option. 71

B2

⊕1

DC reactor connection

These terminals are shorted at shipment. Remove the shorting bar between ⊕1

and ⊕2 when connecting a DC reactor to this terminal.

309

⊕2

⊕1

DC power supply input For connecting a DC power supply. –

⊖

(2 terminals)

Ground Grounding Terminal 60

u

Wire Gauges and Tightening Torque

Select the appropriate wires and crimp terminals from Table 3.2 through Table 3.4.

Note: 1. Wire gauge recommendations based on drive continuous

current ratings using 75 °C 600 Vac vinyl-sheathed wire assuming ambient

temperature within 30 °C and wiring distance shorter than 100 m.

2. Terminals ⊕1, ⊕2, ⊖, B1 and B2 are for connecting optional devices such as a braking resistor. Do not connect other non-specified

devices to these terminals.

• Consider the amount of voltage drop when selecting wire gauges. Increase the wire gauge when the voltage drop is

greater than 2% of motor rated voltage. Ensure the wire gauge is suitable for the terminal block. Use the following

formula to calculate the amount of voltage drop:

•

Line drop voltage (V) =

3 x wire resistance (Ω/km) x wire length (m) x current (A) x 10

-3

• Refer to instruction manual TOBP C720600 00 for braking unit or braking resistor unit wire gauges.

• Refer to UL Standards Compliance on page 441 for information on UL compliance.

n

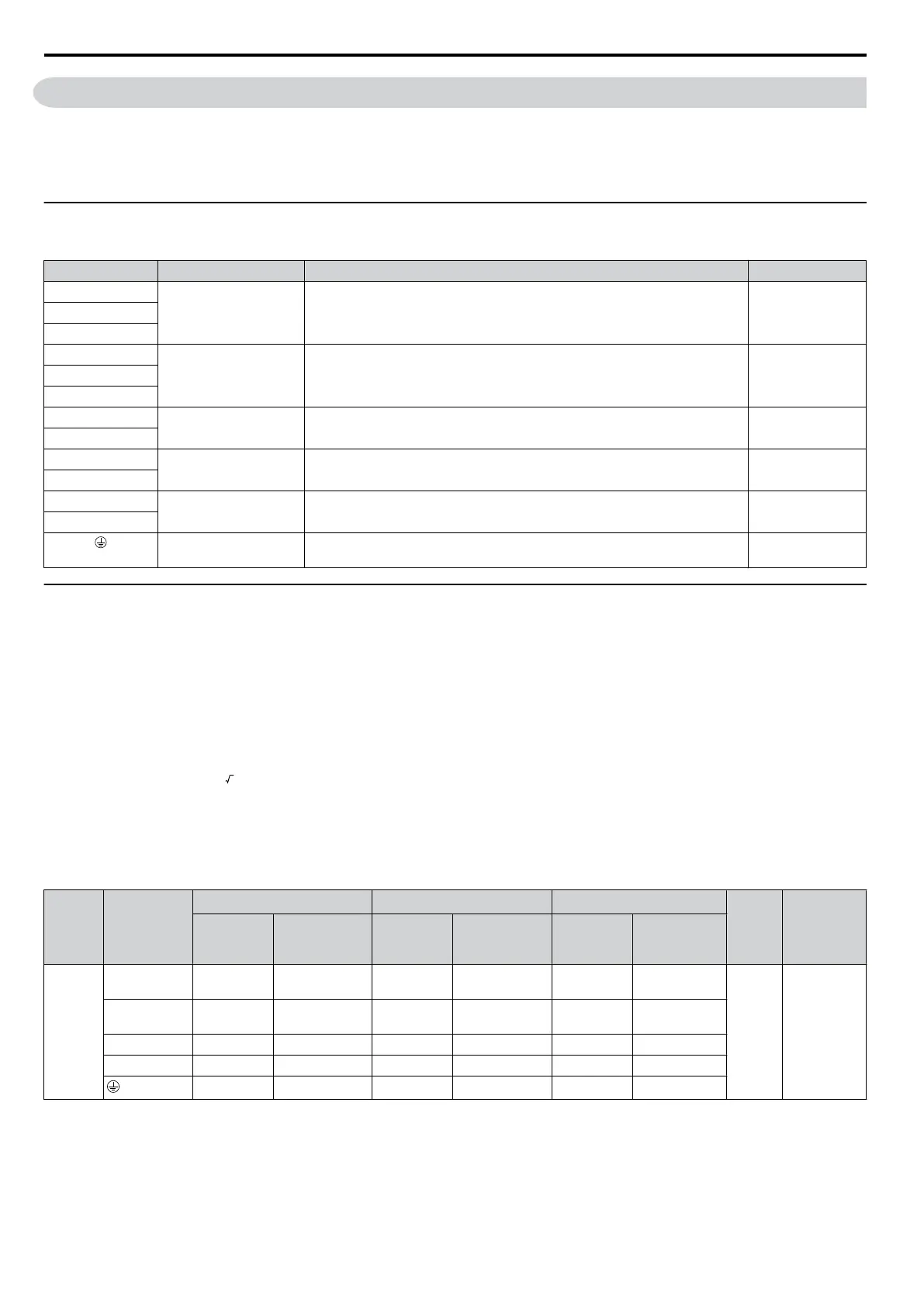

Single-Phase 200 V Class

Table 3.2 Wire Gauge and Torque Specifications

Drive

Model

Terminal

For Japan and Asia

<1>

For United States

<2>

For Europe and China

<3>

Screw

Size

Tightening

Torque

N•m (lb.in.)

Recomm.

Gauge

mm

2

Wire Range

mm

2

Recomm.

Gauge

AWG, kcmil

Wire Range

AWG, kcmil

Recomm.

Gauge

mm

2

Wire Range

mm

2

BA0001

BA0002

BA0003

R/L1, S/L2,

T/L3

2 0.75 to 2 14 18 to 14 2.5 0.75 to 2.5

M3.5

0.8 to 1.0

(7.1 to 8.9)

U/T1, V/T2,

W/T3

2 0.75 to 2 14 18 to 14 2.5 0.75 to 2.5

⊖, ⊕1, ⊕2

2 0.75 to 2 – 18 to 14 – 0.75 to 2.5

B1, B2 2 0.75 to 2 – 18 to 14 – 0.75 to 2.5

2 0.75 to 2 14 18 to 14 2.5 0.75 to 2.5

3.6 Main Circuit Wiring

56

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

Loading...

Loading...