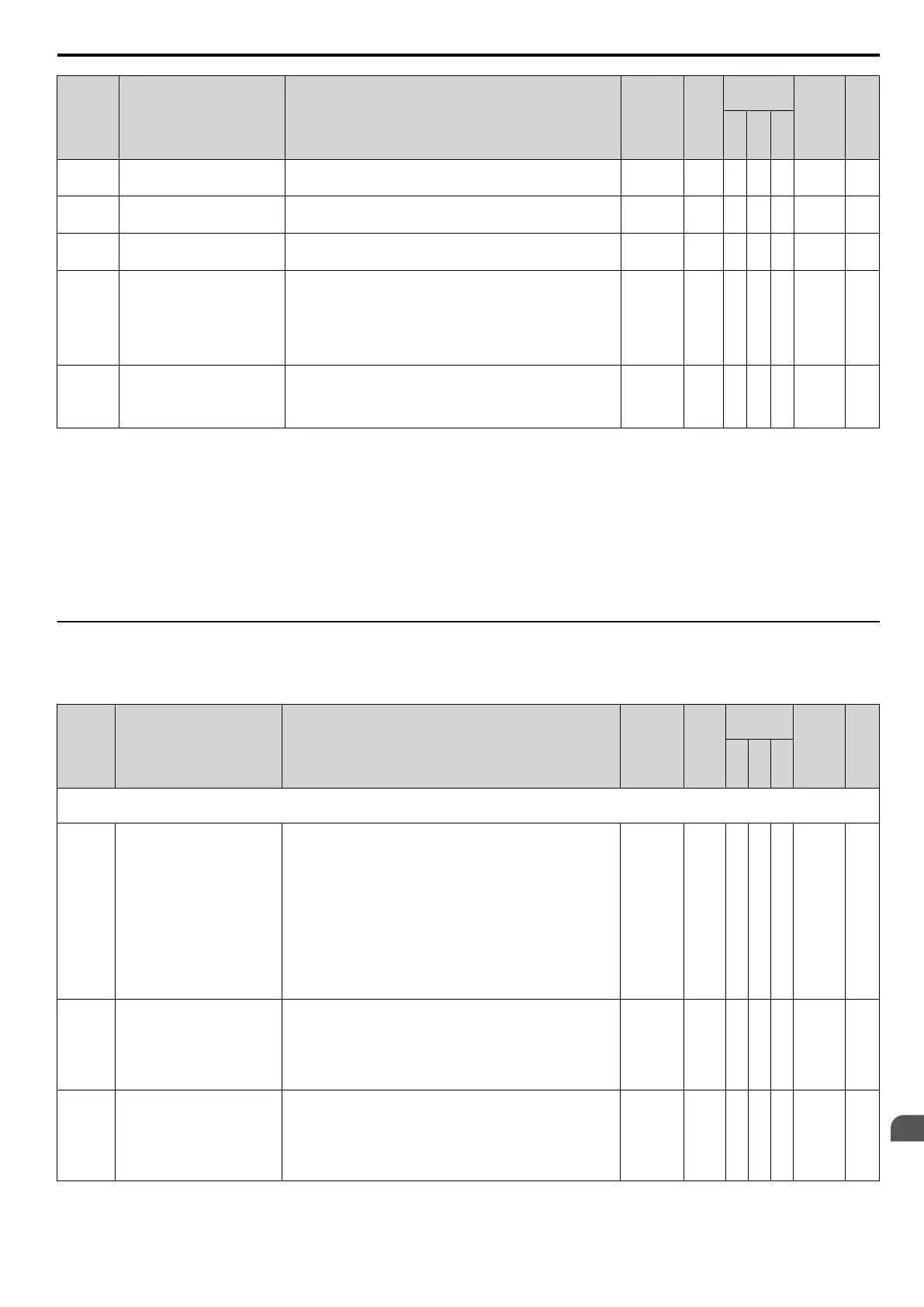

No. Name Description Range Def.

Control

Mode

Addr.

Hex

Pg.

V/

f

O

L

V

P

M

H6-03

<2>

Pulse Train Input Gain

Sets the level of the value selected in H6-01 when a

frequency with the value set in H6-02 is input.

0.0 to

1000.0

100.0

%

A A A 42E 202

H6-04

<2>

Pulse Train Input Bias

Sets the level of the value selected in H6-01 when 0 Hz is

input.

-100.0 to

+100.0

0.0% A A A 42F 202

H6-05

<2>

Pulse Train Input Filter Time

Sets the pulse train input filter time constant.

0.00 to

2.00

0.10 s A A A 430 202

H6-06

<2>

Pulse Train Monitor

Terminal MP Selection

Select the pulse train monitor output function (value of the

o-oo part of Uo-oo).

Refer

to U: Monitors on page 371

for the list of U monitors.

Example: To select U5-01, set “501. ”When not using this

parameter or when using in the through mode, set “000”.

<5>

000, 031,

101, 102,

105, 116,

501, 502;

801 to

809

102 A A A 431 202

H6-07

<2>

Pulse Train Monitor

Scaling

Sets the terminal MP output signal frequency when the

monitor

value is 100%. Set H6-06 to 102

and H6-07 to 0 to

make the pulse train monitor output equal to the output

frequency.

0 to

32000

1440

Hz

A A A 432 202

<1> The availability of certain functions depends on the control method used.

<2> Parameter can be changed during Run.

<3> If this parameter is set to 0, the drive will be unable to respond to MEMOBUS/Modbus commands.

<4> Default setting is determined by drive software version.

PRG: 1016 and later: 100 to 32000 Hz

PRG: 1015 and earlier: 1000 to 32000 Hz

<5>

When set for sourcing, +5

V/1.5 kΩ or higher, +8 V/3.5 kΩ or higher, +10 V/10 kΩ or higher. When set for sinking, the external power supply

should be +12 Vdc, ±5% with 16 mA or less.

Note: Cycle power to the drive to enable MEMOBUS/Modbus settings.

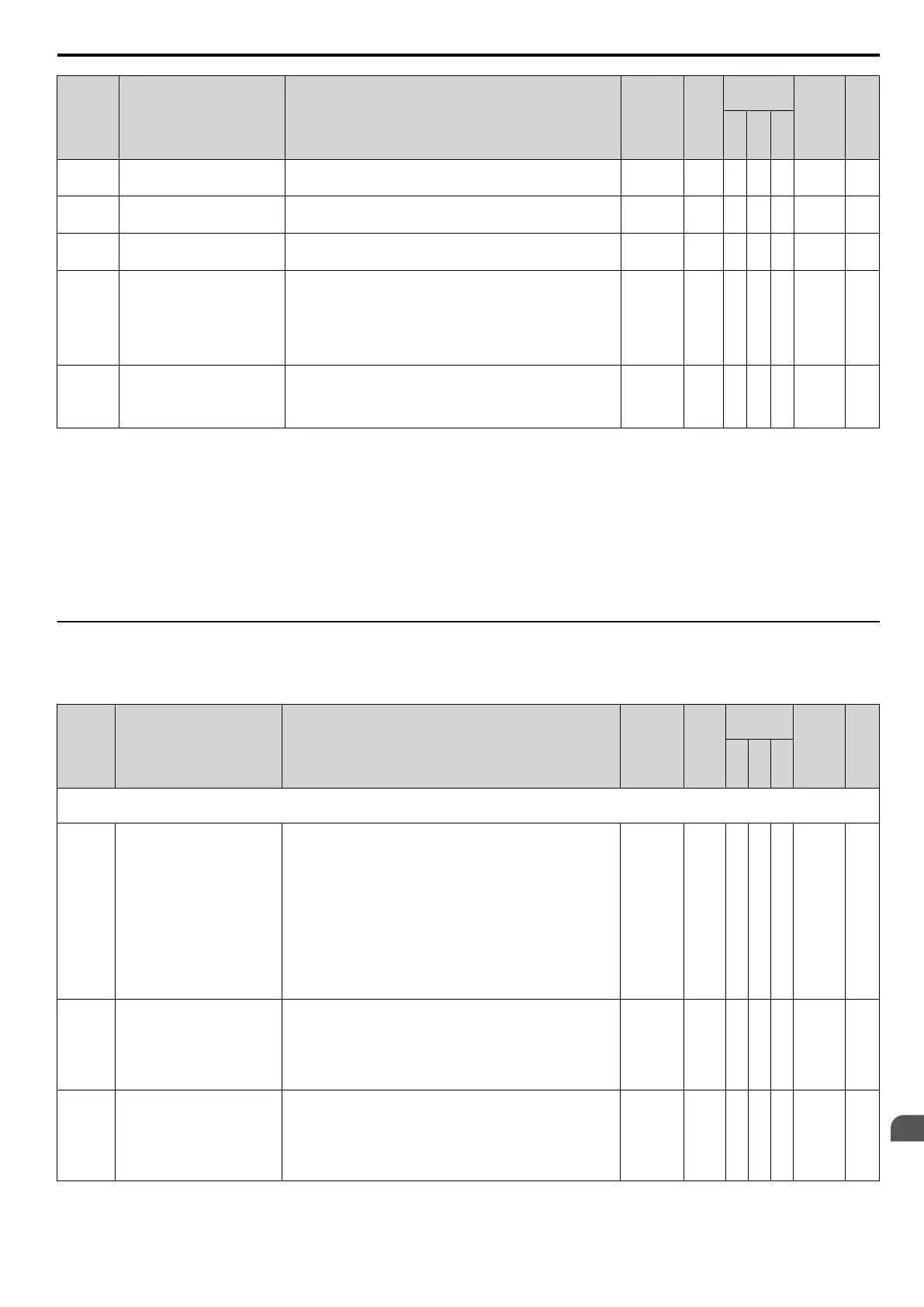

u

L: Protection Function

L parameters provide protection to the drive and motor, such as: control during momentary power loss, Stall Prevention,

frequency detection, fault restarts, overtorque detection, torque limits and other types of hardware protection.

No. Name Description Range Def.

Control

Mode

Addr.

Hex

Pg.

V/

f

O

L

V

P

M

L1: Motor Protection Functions

Use L1 parameters to configure motor protective functions.

L1-01

Motor Overload Protection

Selection

Sets the motor thermal overload protection (oL1) based on

the cooling capacity of the motor.

0: Disabled

1: General Purpose Motor (Standard Fan Cooled)

2: Drive Dedicated Motor with a Speed Range of 1:10

3: Vector Motor with a Speed Range of 1:100

4: PM Motor with Variable Torque

6: General Purpose Motor (50 Hz)

<1>

Note:

When using multiple motors the drive may

not be able

to provide protection, even if overload is enabled in L1-01.

Set L1-01 to 0 and ensure each motor has separate thermal

relays installed.

0 to 4; 6

1

<2>

S S S 480 203

L1-02

Motor Overload Protection

Time

Sets the motor thermal overload protection (oL1) time.

A larger L1-02 time will increase the time for an oL1 fault

to occur.

This parameter does not typically require adjustment.

Should be set in accordance with the overload tolerance of

the motor.

0.1 to 5.0

1.0

min

A A A 481 205

L1-03

Motor Overheat Alarm

Operation Selection (PTC

input)

Sets operation when the motor temperature analog input

(H3-02/10 = E) exceeds the oH3 alarm level.

0: Ramp to Stop

1: Coast to Stop

2: Fast-stop using C1-09

3: Alarm Only (“oH3” will flash)

0 to 3 3 A A A 482 206

B.2 Parameter Table

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

357

B

Parameter List

Loading...

Loading...