n

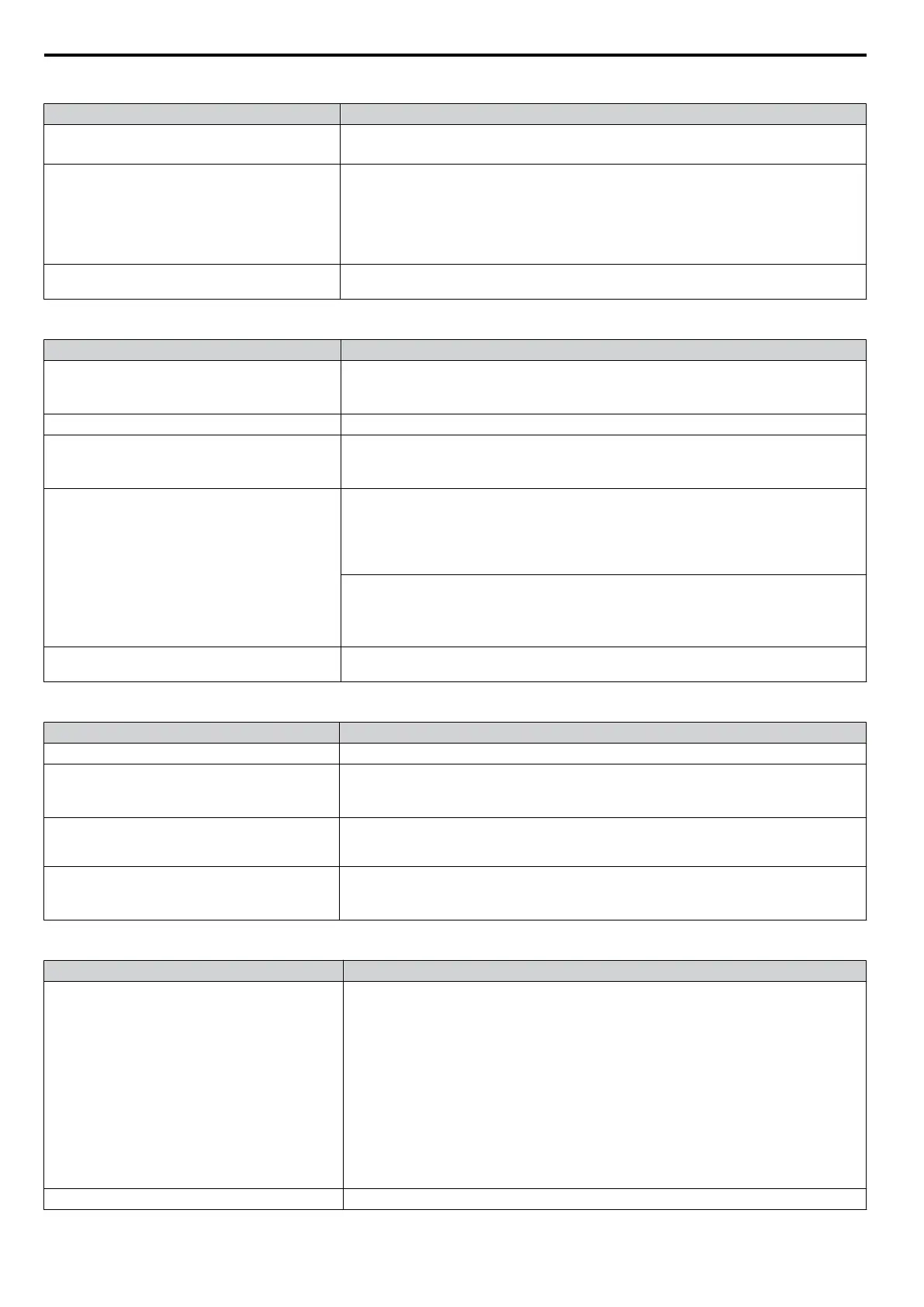

Poor Speed Control Accuracy

Cause Possible Solutions

Drive reached the slip compensation limit.

• Check the slip compensation limit (C3-03).

• Increase the value set to C3-03.

Motor-rated voltage is set too high in Open Loop

Vector Control.

• The input voltage for the drive determines the maximum output voltage. A drive with an

input of 200 Vac can only output a maximum of 200 Vac. Open Loop Vector Control

sometimes calculates an output voltage reference value that exceeds the maximum drive

output voltage level, resulting in a loss of speed control accuracy.

• Use a motor with a lower voltage rating (a vector control motor).

• Increase the input power voltage.

Auto-Tuning did not complete properly for Open

Loop Vector Control.

• Perform Auto-Tuning again.

n

Deceleration Takes Longer Than Expected with Dynamic Braking Enabled

Cause Possible Solutions

L3-04 is set incorrectly.

• Check the Stall Prevention Level during deceleration (L3-04).

• If a braking resistor option has been installed, disable Stall Prevention during deceleration

(L3-04 = “0”).

The deceleration time is set too long. Set deceleration to more appropriate time (C1-02, C1-04, C1-06, C1-08).

Insufficient motor torque.

• Assuming parameter settings are normal and that no overvoltage occurs when there is

insufficient torque, it is likely that the demand on the motor has exceeded the motor capacity.

• Use a larger motor.

Reaching the torque limit.

• Check the settings for the torque limit (L7-01 through L7-04).

• If the torque limit is enabled, deceleration might take longer than expected because the drive

cannot output more torque than the limit setting. Ensure the torque limit is set to a large

enough value.

• Increase the torque limit setting.

• If multi-function analog input terminal A1 or A2 is set to torque limit (H3-02 or H3-10

equals 10, 11, 12, or 15), ensure that the analog input levels are set to the correct levels.

• Ensure H3-02 and H3-10 are set to the right levels.

• Ensure the analog input is set to the correct value.

Load exceeded the internal torque limit determined

by the drive rated current.

Switch to a larger capacity drive.

n

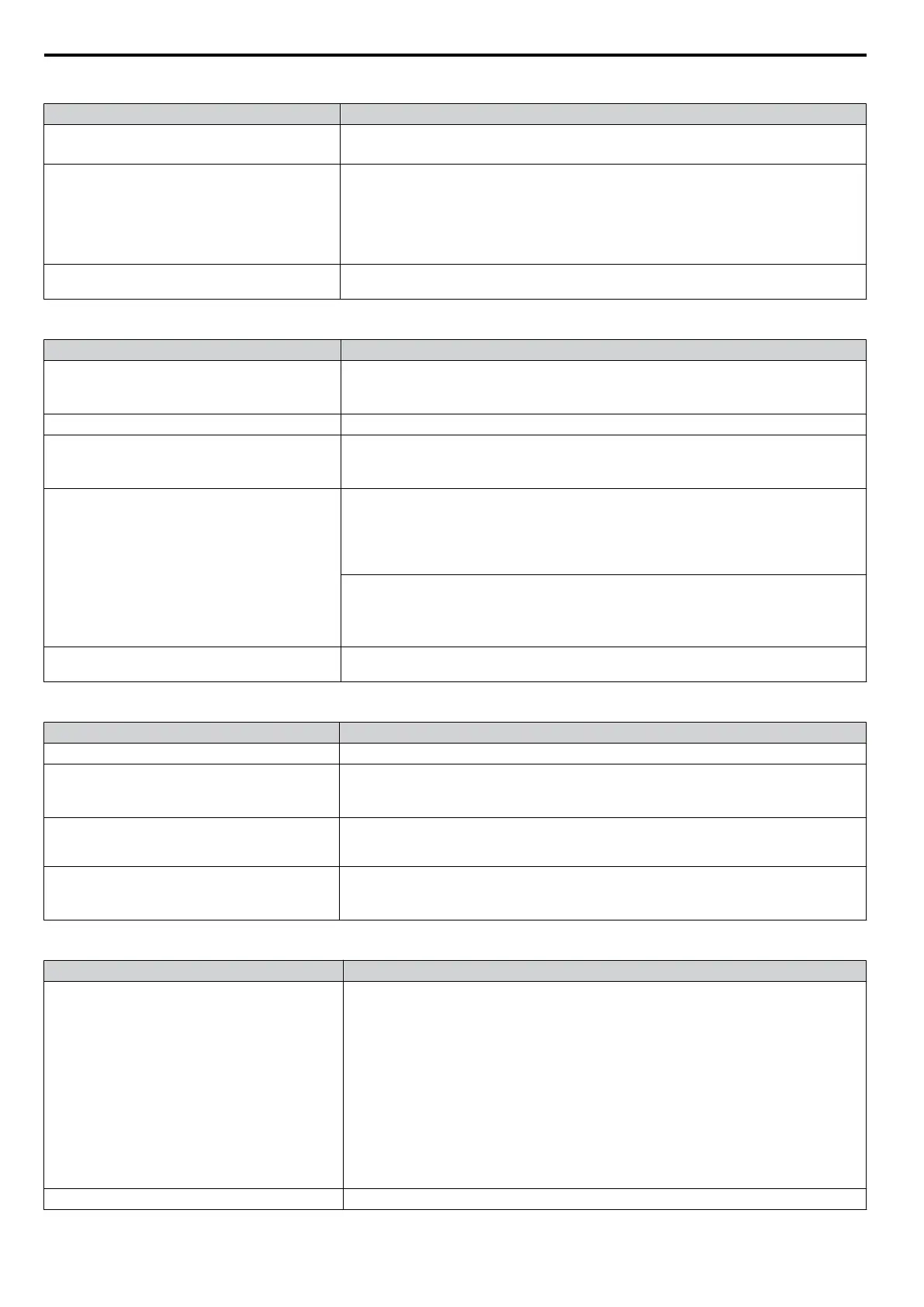

Motor Hunting Occurs When Operating With a Light Load

Cause Possible Solutions

Carrier frequency is too high. Lower the carrier frequency setting C6-02.

Large V/f setting value at low speeds triggers

overexcitation.

• Select the proper V/f pattern (E1-03).

• Use parameters E1-04 through E1-10 to set the V/f pattern in relation to the load

characteristics.

The maximum output frequency and the base

frequency reference are not set properly in

relationship to each other.

Set the proper values for the maximum output frequency and base frequency (E1-04, E1-06).

Hunting Prevention is disabled (V/f control only).

• Enable Hunting Prevention by setting n1-01 = “1”.

• (OLV only) Increase the speed feedback detection control gain and time constant (n2-01,

n2-02).

n

Load Falls When Brake is Applied (Hoist-Type Applications)

Cause Possible Solutions

The timing for the brake to close and release is not

set properly.

Use frequency reference detection for closing and releasing the brake.

• At start: Release the brake after creating enough torque.

• At stop: Close the brake when the motor still produces torque.

Make the following setting changes to hold the brake:

• Set the frequency detection inactive during baseblock (L4-07 = 0).

• Multi-function contact output terminal will switch on when the output frequency is greater

than the frequency detection level set in L4-01. Set L4-01 between 1.0 and 3.0 Hz.

• Slipping may occur when stopping because hysteresis is used in Frequency Reference 2

(where the frequency agree setting in L4-02 is 2.0 Hz). To prevent this, change the setting

to 0.1 Hz.

• Do not use the multi-function contact output setting “During Run” (H2-01 = 0) for the brake

signal.

Insufficient DC Injection Braking. Increase the amount of DC Injection Braking (b2-02).

6.9 Troubleshooting without Fault Display

284

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

Loading...

Loading...