Washer Qualification Liquid Tests | 253

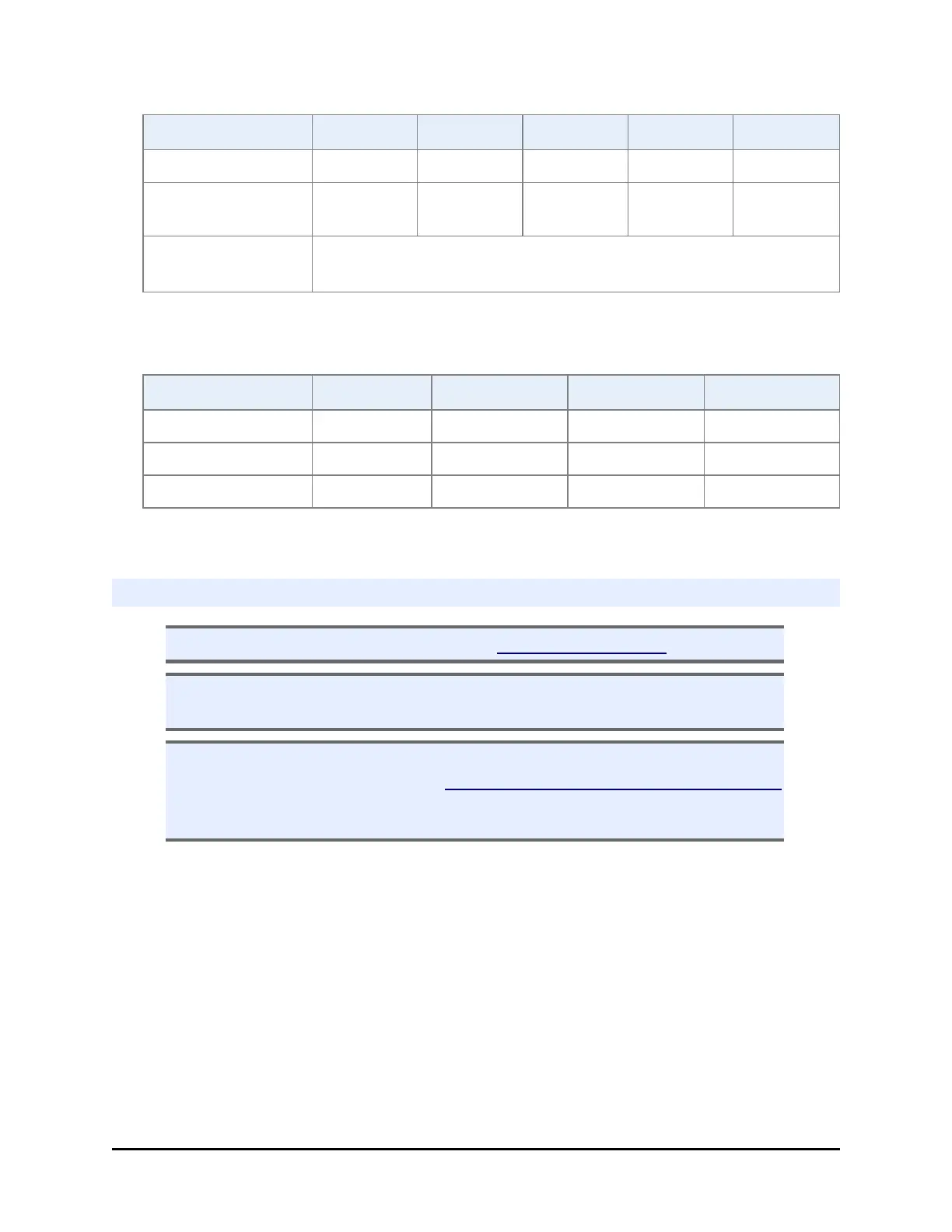

Parameters 6-Well 12-Well 24-Well 48-Well 384-well

Flow Rate 5 5 5 5 5

Z-axis/Dispense

Height

465 460 452 460 333

Pre-dispense

For all manifold types enable and set its Volume to 300 µL and

Number of cycles to 2.

Retain default values for all other parameters.

Evacuation Efficiency Protocols

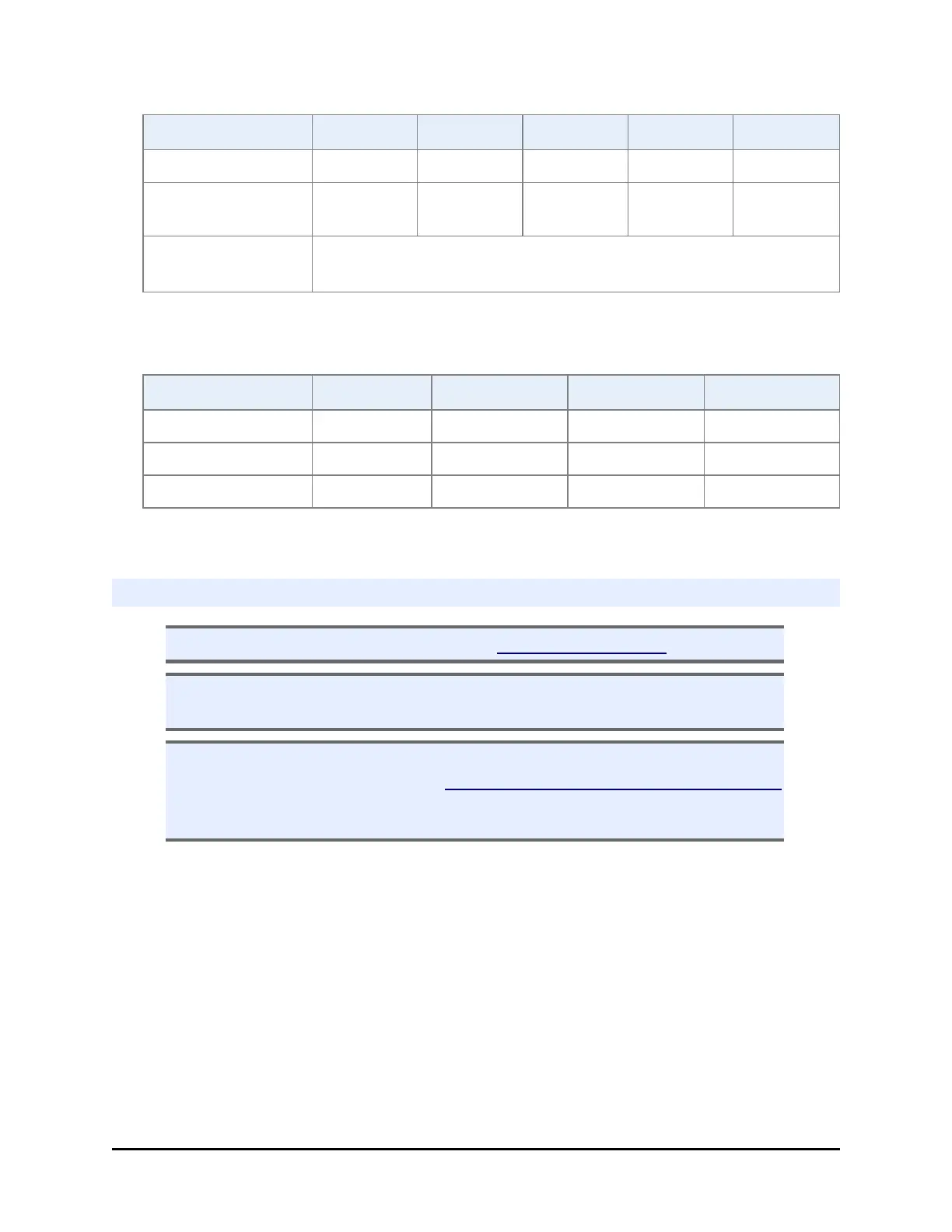

Parameters 6-Well 12-Well 24-Well 48-Well

Travel Rate 0 1 1 1

Z-axis 45 51 51 42

X-axis 350 222 150 96

Retain default values for all other parameters.

Dispense Precision and Accuracy Test

n Find a list of the supplies you will need at Materials on page 251.

n Save the plate! When this test is complete, use the filled plate to perform the

Evacuation Efficiency Test.

n Prerequisite for plate types other than 96-Well: Create the protocols

needed to test your manifold. See Create Washer Qualification Protocols

on the previous page. One time only! (Predefined protocols are provided

with the instrument qualification package (PN 1260521).

1. Fill a supply bottle with 2 liters of deionized or distilled water and run the W-

DAY_RINSE protocol once or twice to flush the fluid lines and manifold.

2. Fill a supply bottle with 1200 mL of Solution #3.

3. Run W-DAY_RINSE again to prime the washer with the solution.

4. Place a new microplate on the balance and zero the balance.

5. Place the plate on the carrier and run the QC_96_DISP_TEST or the protocol

you created for your manifold. The protocol dispenses solution to each well of

the plate. It does not evacuate the solution.

BioTek Instruments, Inc.

Loading...

Loading...