260

Powerhead

Powerhead Assembly

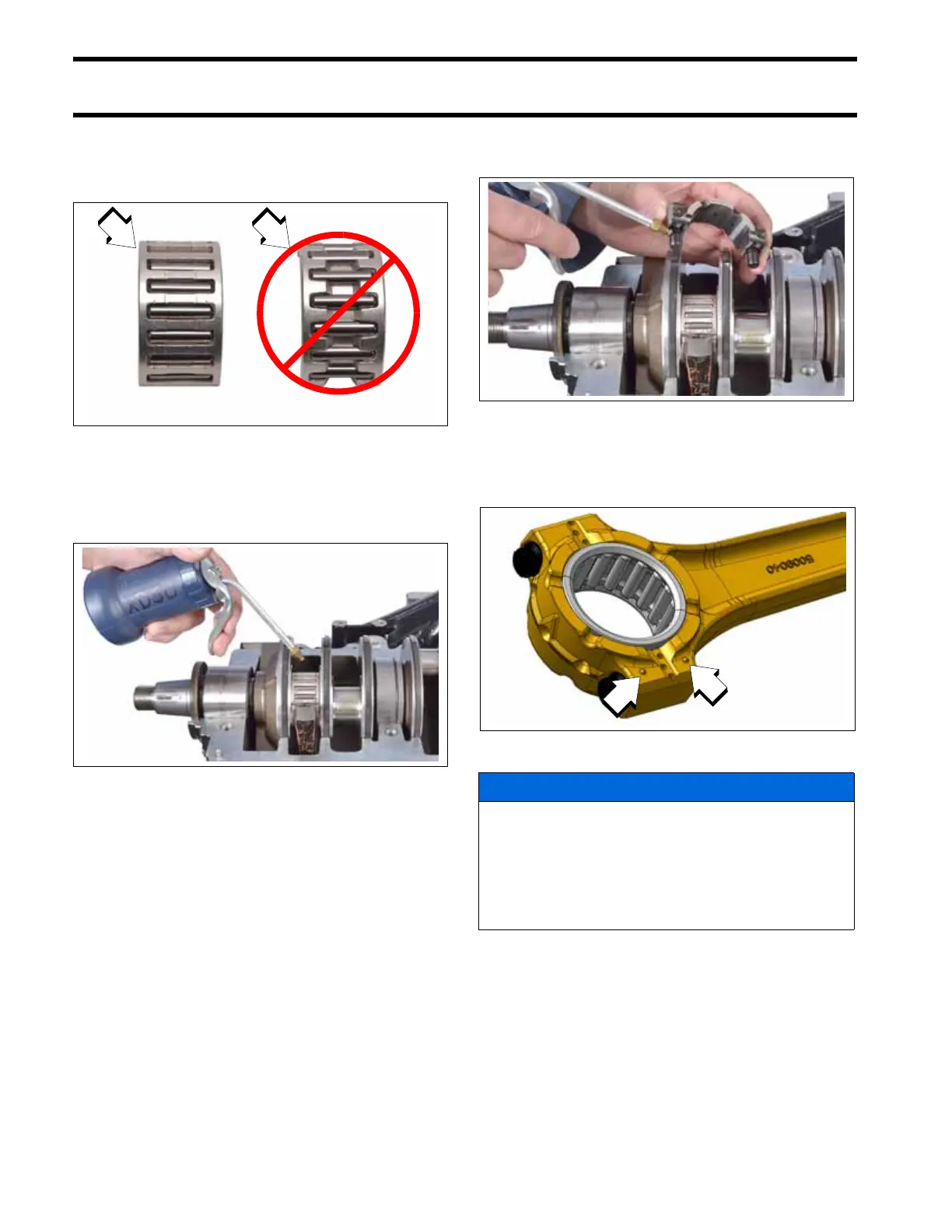

bearings each. Do NOT substitute earlier Evinrude

E-TEC connecting rod bearing halves which con-

tain only 8 needle bearings each.

Carefully pull connecting rod up to crankshaft and

install bearing halves. Lubricate each crankpin

and bearing assembly with outboard lubricant.

Lubricate rod cap screw threads and under screw

head mating surface with outboard lubricant.

Apply outboard lubricant to screw hole threads in

rod, and to screw head mating surface on cap.

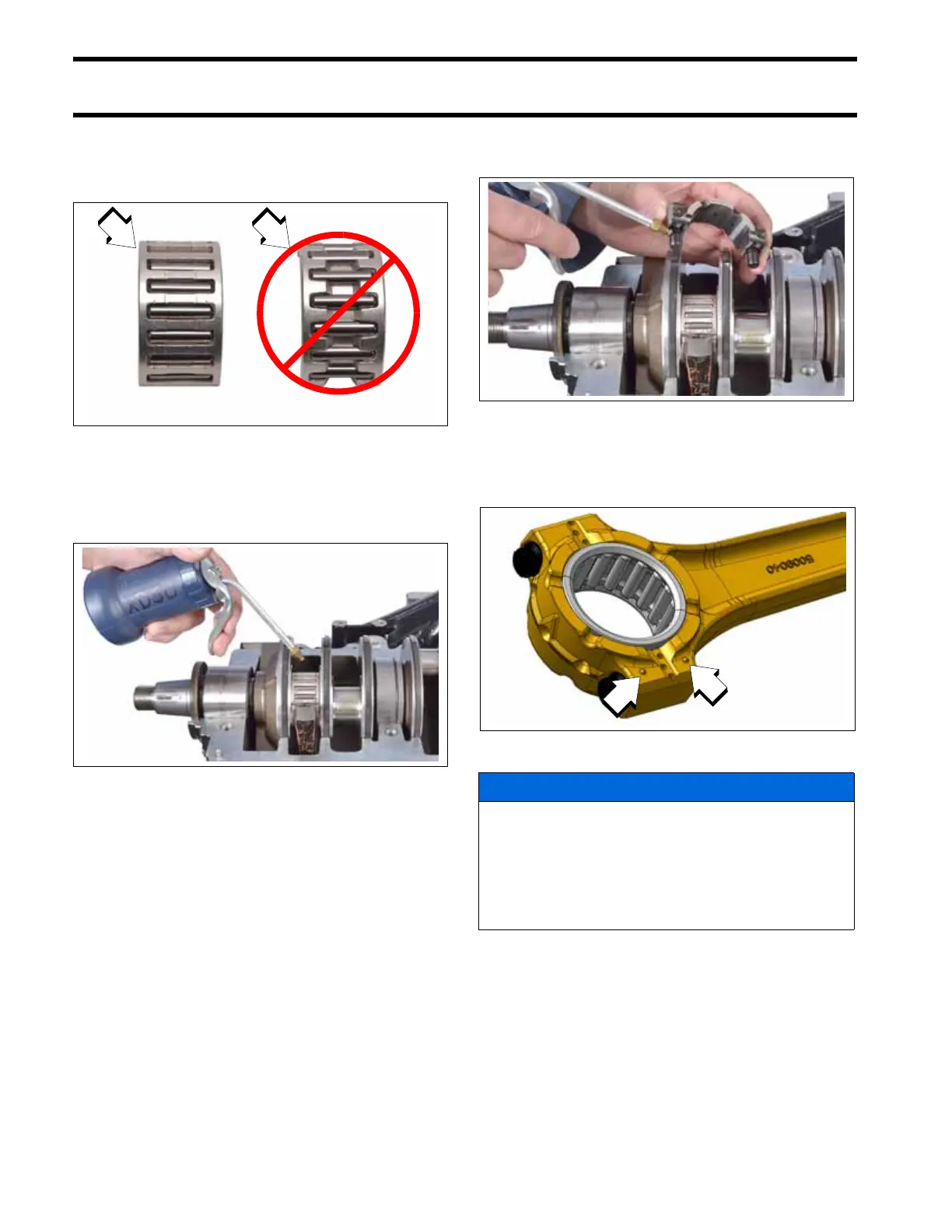

Align dot on rod cap with dot on the connecting

rod.

Install rod cap screws finger tight (NO MORE than

6 in. lbs. (1 N·m) maximum).

IMPORTANT: Be sure alignment dot on rod cap

matches dot on rod and that both dots face fly-

wheel.

Install Rod Cap Alignment Fixture, P/N 396749,

before tightening rod cap screws. Align the flat

marked “SET” on the rod adjustment stop with the

arrow on the frame. Position the stop at the high-

1. G2 Connecting rod bearing half

2. G1 Connecting rod bearing half

009686

009715

009716

1. Alignment dots

009717

NOTICE

Tightening rod cap screws without Alignment

Fixture, P/N 396749, or using an incorrect

procedure could cause permanent damage to

the connecting rod and crankshaft. To main-

tain accurate torque values, keep torque

wrench extension length to a minimum.

Loading...

Loading...