6

6

6-3

6-3

Troubleshooting > Troubleshooting Items > Image Faults > Smudged/Streaked

Troubleshooting > Troubleshooting Items > Image Faults > Smudged/Streaked

Troubleshooting Items

Image Faults

■

Smudged/Streaked

●

Bleeding (smear) occurs immediately after the power is turned on for

the rst time for the day

Description

There is sometimes a case where the difference of temperature between air and inside of the

machine causes moisture to occur on the toner immediately after the power is turned on for

the rst time for the day.

As a result, when the toner transferred on a sheet at the time of initial printing passes through

the xing assembly, moisture on the toner is vaporized into steam, causing breading (smear)

to occur.

Field Remedy

Prevent bleeding using the following user mode items.

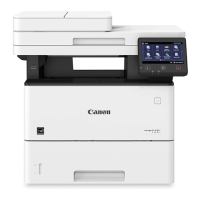

Setting items Setting value Description Additional information

Adjustment/

Maintenance >

Special Processing

> Special Mode Z

Not used,Mode 1

through 4 (Factory

setting: Mode 2)

Make a setting to perform

thinning of printed image

data by processing of the

controller. When the value

set for the mode increases,

the amount of thinning

increases. (The image

density decreases.)

Printing time does not

increase because the

method of image processing

performed by the controller

is changed. This mode is

less effective than Mode B.

Adjustment/

Maintenance >

Special Processing

> Special Mode B

Not used,Mode 1

through 3 (Factory

setting: Not used)

Extend the initial rotation

period by processing of the

engine. When the value

set for the mode increases,

the initial rotation period is

extended.

The initial rotation period

in engine operation is

extended, and printing time

increases. The initial rotation

period for each mode is

shown below. Mode 1: 13

sec, Mode 2: 30 sec, Mode 3:

60 sec

T-6-1

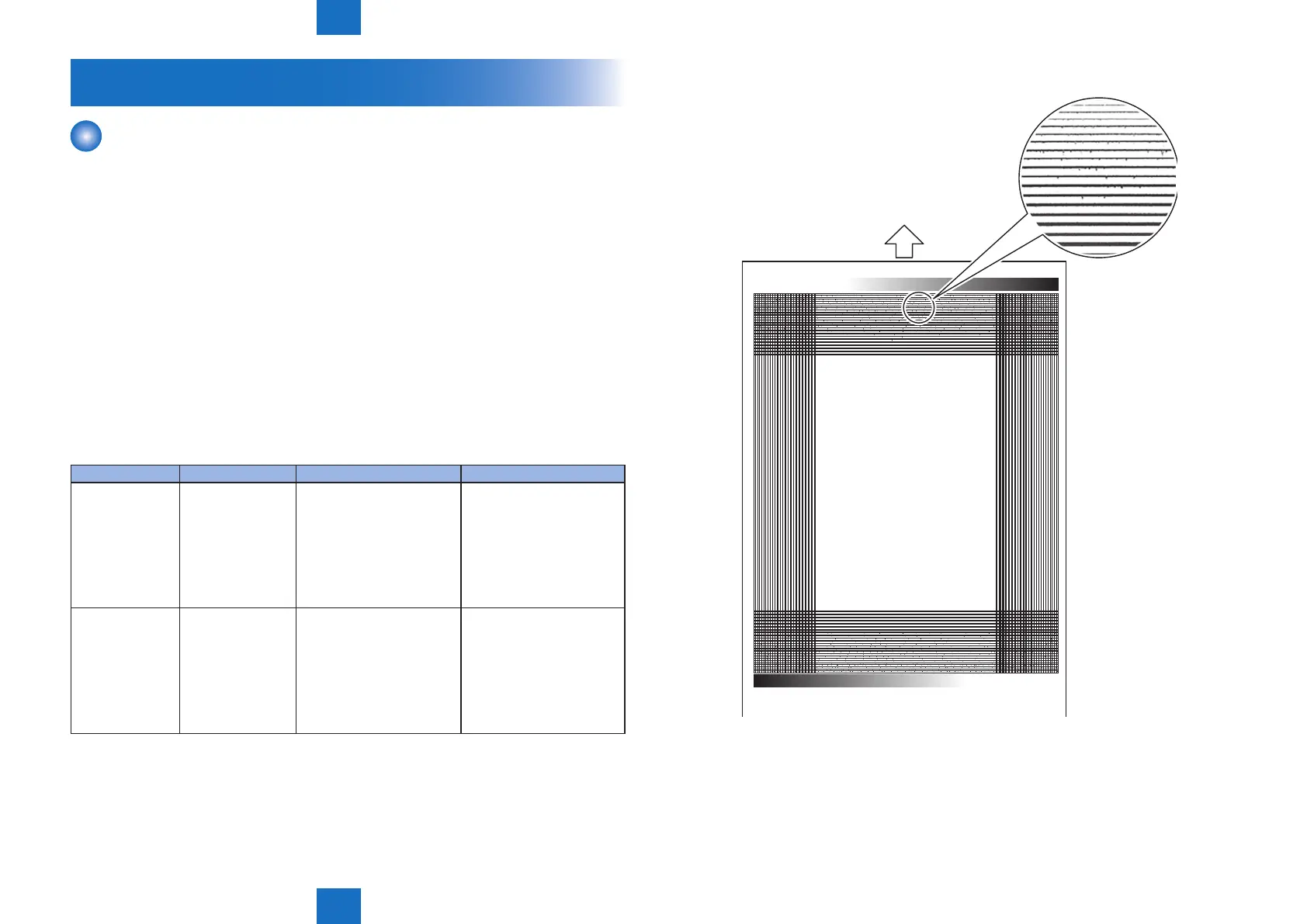

Image sample

F-6-2

Loading...

Loading...