F 73 8

A

If a different level of slack is detected during the measurement process, proceed as

follows:

- Screw head section for flat nipple (tool

box) onto the grease gun.

- Refill the chain tensioner with grease

at the filler connection (A), then

remove the grease gun.

- Check the chain tension once again,

as described above.

A

If the tension is too high: see section

"Relieving the chain".

A

Repeat this procedure on both drive

units!

Relieving the chain:

f

The grease in the tensioning element is

under pressure. Carefully and slowly un-

screw the filling valve, but not too far.

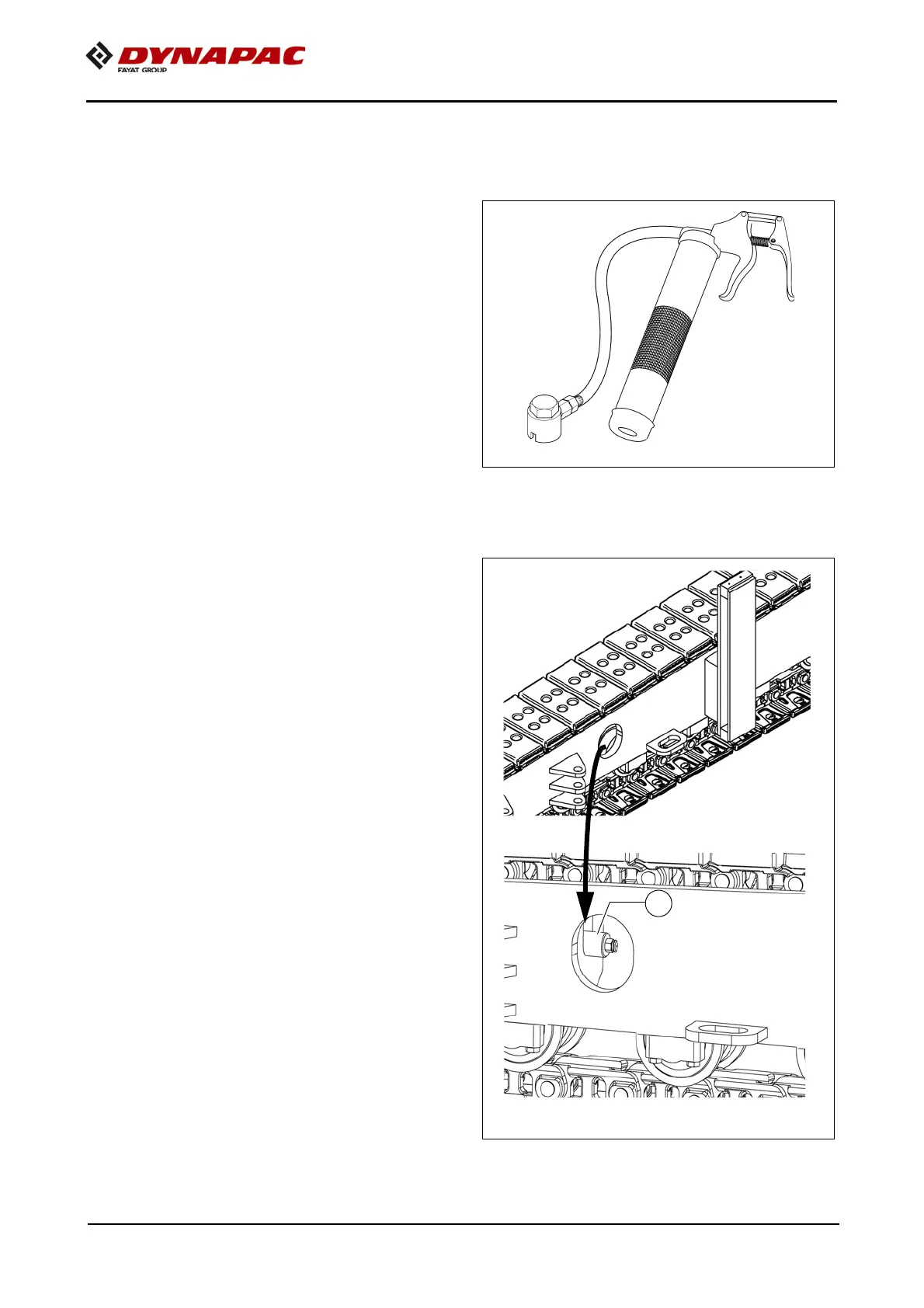

- Unscrew the lubricating nipple (A) on

the grease tensioner using a tool until

the grease is able to emerge from the

nipple's lateral hole.

A

The idler wheel moves back independ-

ently or must be reset manually.

Loading...

Loading...