Lenze · 8400 HighLine · Reference manual · DMS 12.0 EN · 06/2017 · TD23 1364

17 Function library

17.1 Function blocks | L_DFSET_1

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Compensation process

At the input of the second set or actual touch probe pulse, the difference between master and slave

position is detected which is then provided via the nSpeedSetOut_v speed output and equivalently

as position at .

In C01073/1

, the following bit coded settings can be made for the compensation procedure:

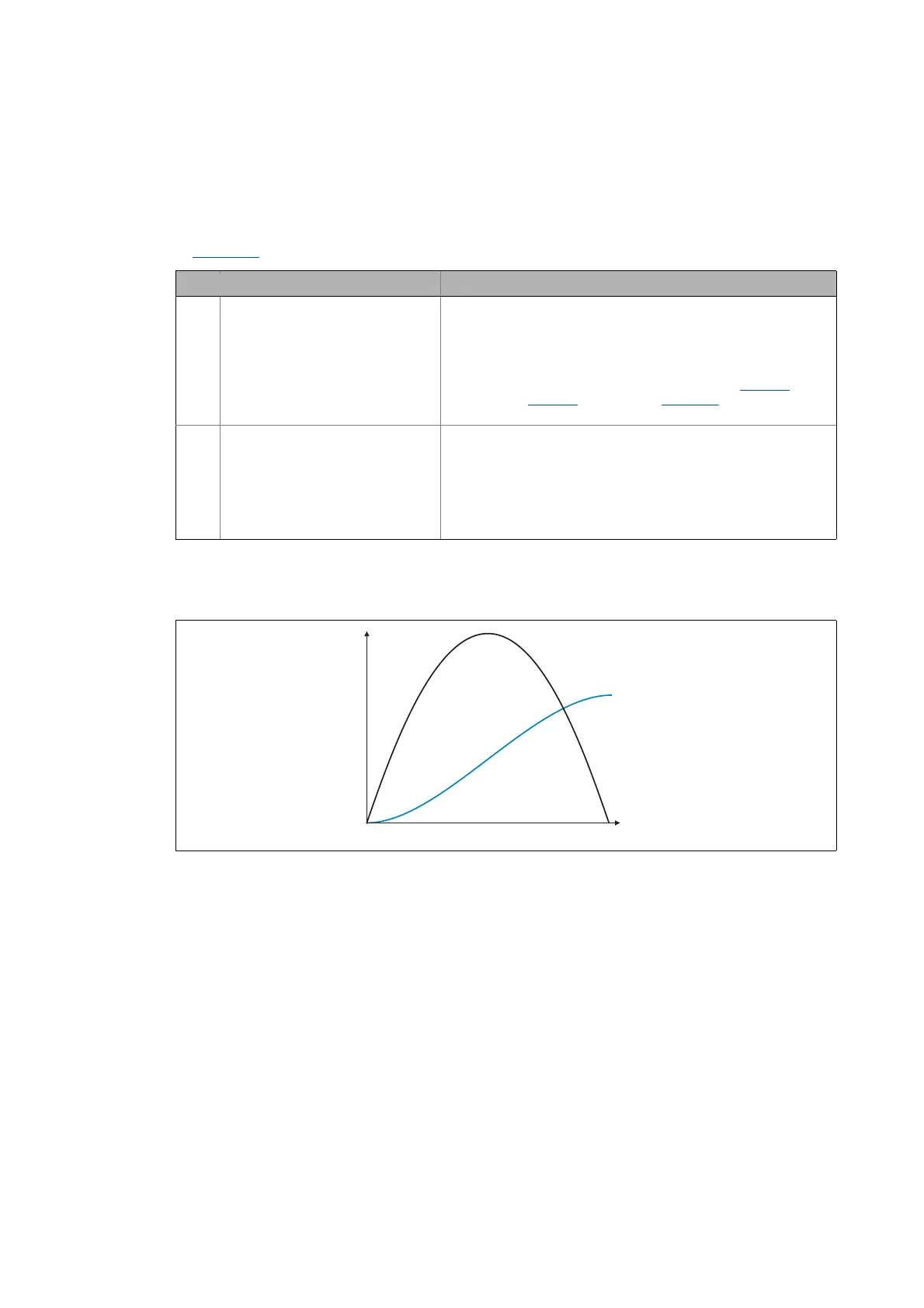

The following illustration shows a compensating process after the marks have been detected. The

speed is added here as a parabola to the line speed. (The scaling in this diagram does not correspond

to reality)

[17-39] Example: Compensation process

setting Info

Bit 1 Angle correction with polynomial If this bit is set (Lenze setting),the compensating movement is

rounded by polynomial.

• The angle error to be compensated is limited to ±1073741823

increments due to the system. This applies in general when the

L_DFSET_1 carries out the compensation.

• The maximum compensating speed can be set in C1069/2

. When

"0" is set in C1069/2

if activated in C01075/1, the angle error is

measured and output to dnPosDiffOut_p.

Bit 2 External angle correction

From version 13.00.00

If this bit is set, the FB L_DFSET_1 does not compensate any angle

errors.

• Every time the angle errors have been measured, the angular

difference is output to dnPosDiffOut_p.

• In addition, a FALSE/TRUE edge is output to bAck. This signal

serves to trigger an external profile generator which

compensates the angular offset via a speed profile additionally.

nSpeedSetOut_v dnPosDiffOut_p

t

v

Loading...

Loading...