5

Service work

Load lift system

Checking and lubricating the fork

prong positioner (special equipment)

ENVIRONMENT NOTE

Observe information regarding the use of

consumables.

Check the hydraulic lines for abrasion spots

and replace the lines if necessary.

Check the hydraulic connections and

mounting elements for secure attachment

and wear. Tighten or replace them as

necessary.

Check the cylinder for damage and leak

tightness.

NOTE

Grease the fork prong positioner after each

cleaning procedure. Use lubricating grease

as set out in the recommendation for consu-

mables. It is better to apply a little grease to

the sliding blocks frequently than to apply a lot

of grease infrequently.

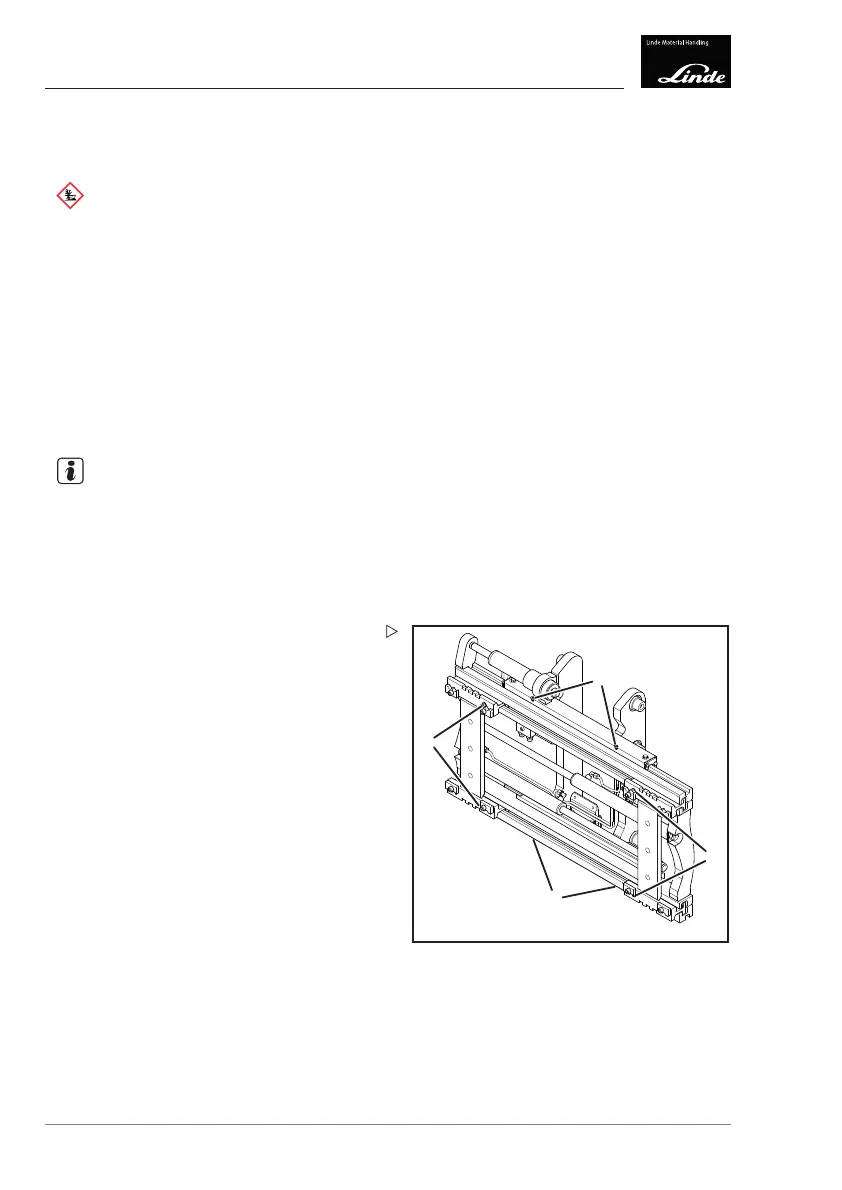

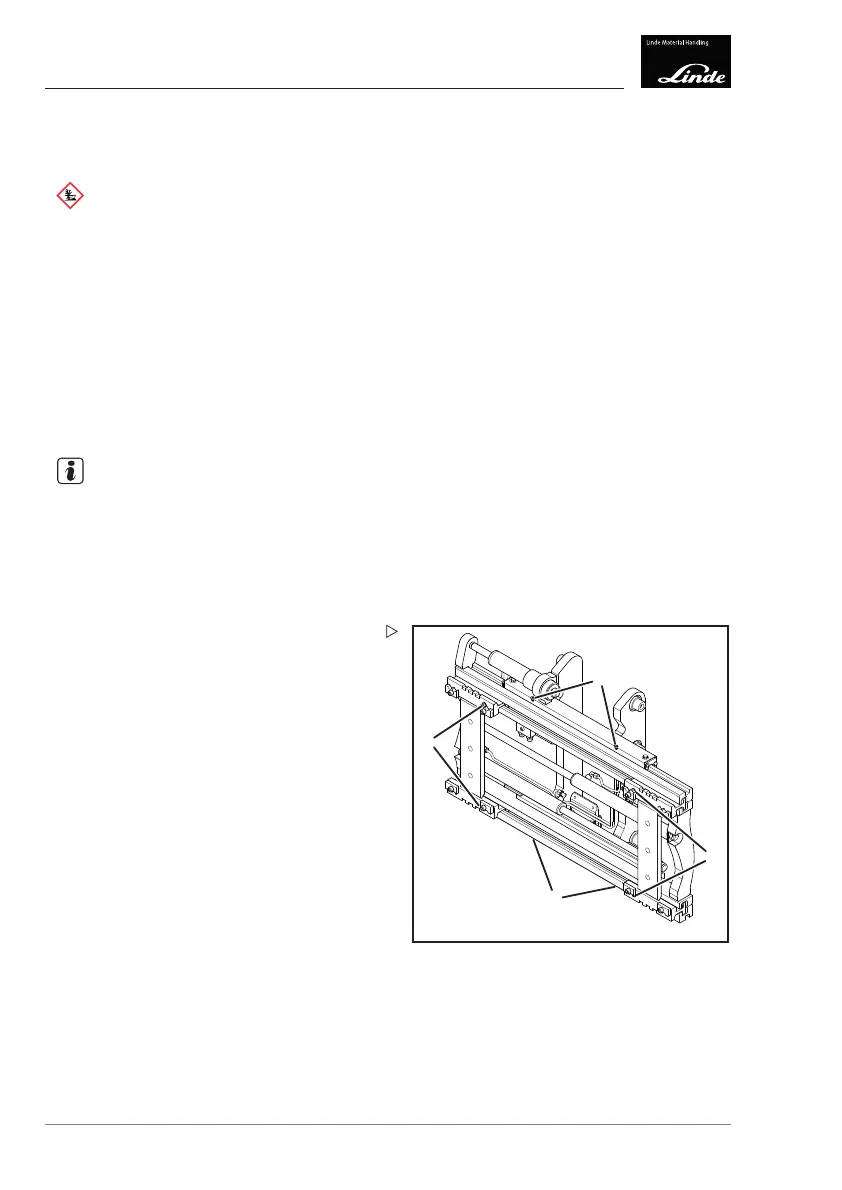

2

1

2

1

d3941489

Move the fork arms s

o that the lubricating

nipples (1) can be a

ccessed.

Lower the fork prong positioner until the fork

arms touch the ground.

Apply lubricating grease to the lubricating

nipples (1) for the wear strips on the fork

carriage at the top and bottom until grease

escapes at the side.

Apply lubricating gr

ease to the lubricating

nipples (2) for the we

ar strips on the guides

at the top and bottom u

ntil grease escapes

at the side.

260 Operating Instructions – 3888011701 EN – 12/2017

Loading...

Loading...