LP-Gas Systems --- Section 7

The Executive 2005

315

If A Freeze Up Occurs:

• Have an LP-Gas distributor purge the tank.

• Have the LP-Gas distributor inject methyl alcohol in the tank.

Damage to the regulator can occur when the tank is overfilled. The regulator is designed to work

with vapor only. This is why the tank is filled to only 80% of its liquid capacity. The other 20% allows

for vaporization of the liquid. The primary vapor valve is located in the vapor section of the tank. In

an overfilled tank, liquefied petroleum can fill the regulator. As the liquid vaporizes, it can freeze the

diaphragm. High tank pressure on a frozen diaphragm can cause a rupture and result in erratic pressure

regulation. This is why it is important to have the LP-Gas pressure checked for proper pressure and

accurate regulation during appliance operation. Erratic pressure regulation dramatically affects refrigera-

tor operation on LP-Gas.

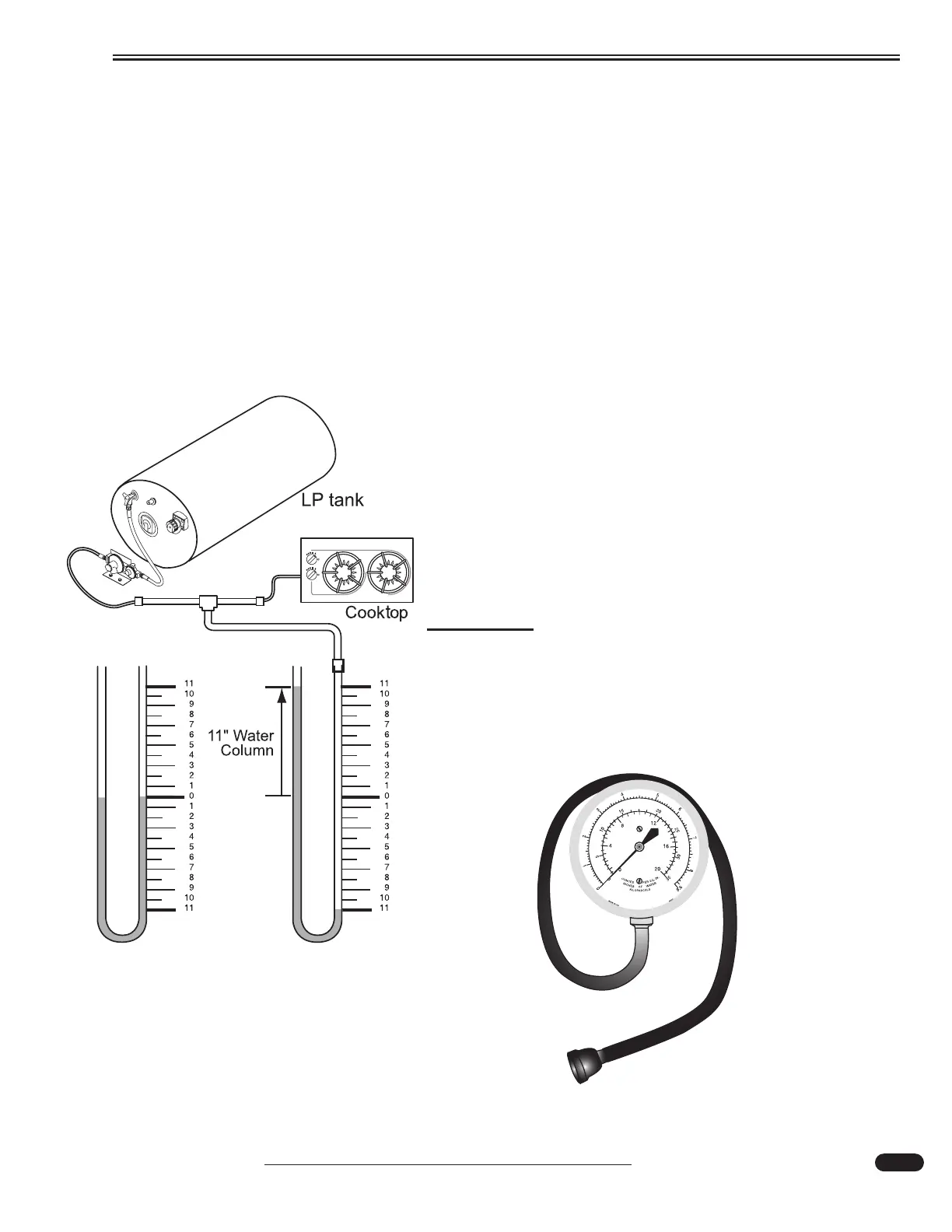

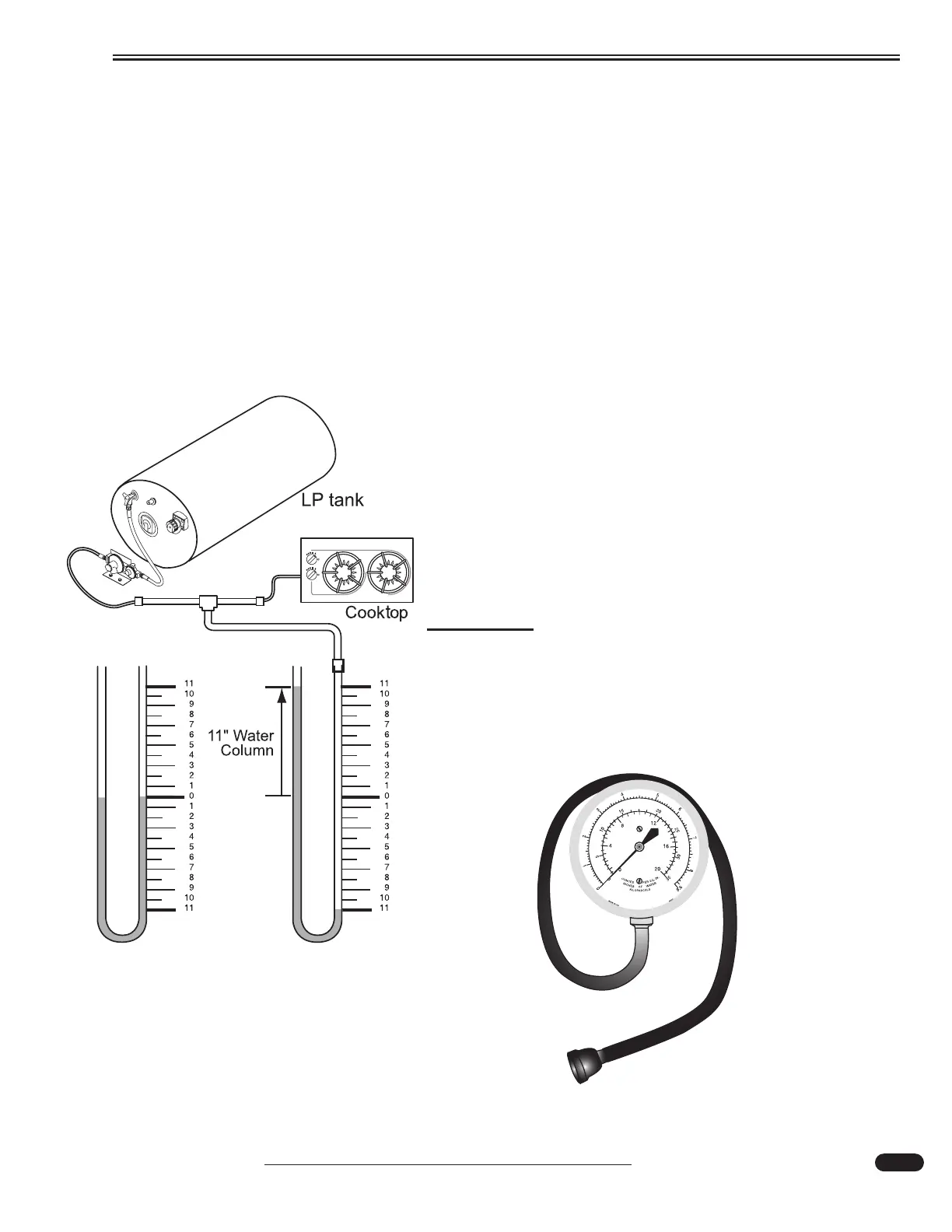

Manometers:

The manometer is the best way to accurately determine

LP-Gas pressure. There are two different styles of manometers:

Gauge and U-tube. Gas pressure is measured in Inches of

Water Column. This is the amount of pressure applied to

one side of a U-shaped tube half filled with water. The amount

of pressure needed to raise the column of water 11" represents

11 Inches of Water Column.

WARNING:

Do not attempt to adjust the regulator. Adjustments

require special equipment. Failure to follow these

instructions may result in a fire or explosion, and can

cause severe personal injury or death. Do not oper-

ate LP-Gas appliances until the LP-Gas pressure is

checked and a leak down test is performed!

050260

050259a

Manometer Gauge for Testing

Type 1

Manometer at Rest

Type 2

U-Tube Testing Layout

Loading...

Loading...