Chassis Information --- Section 10

The Executive 2005

433

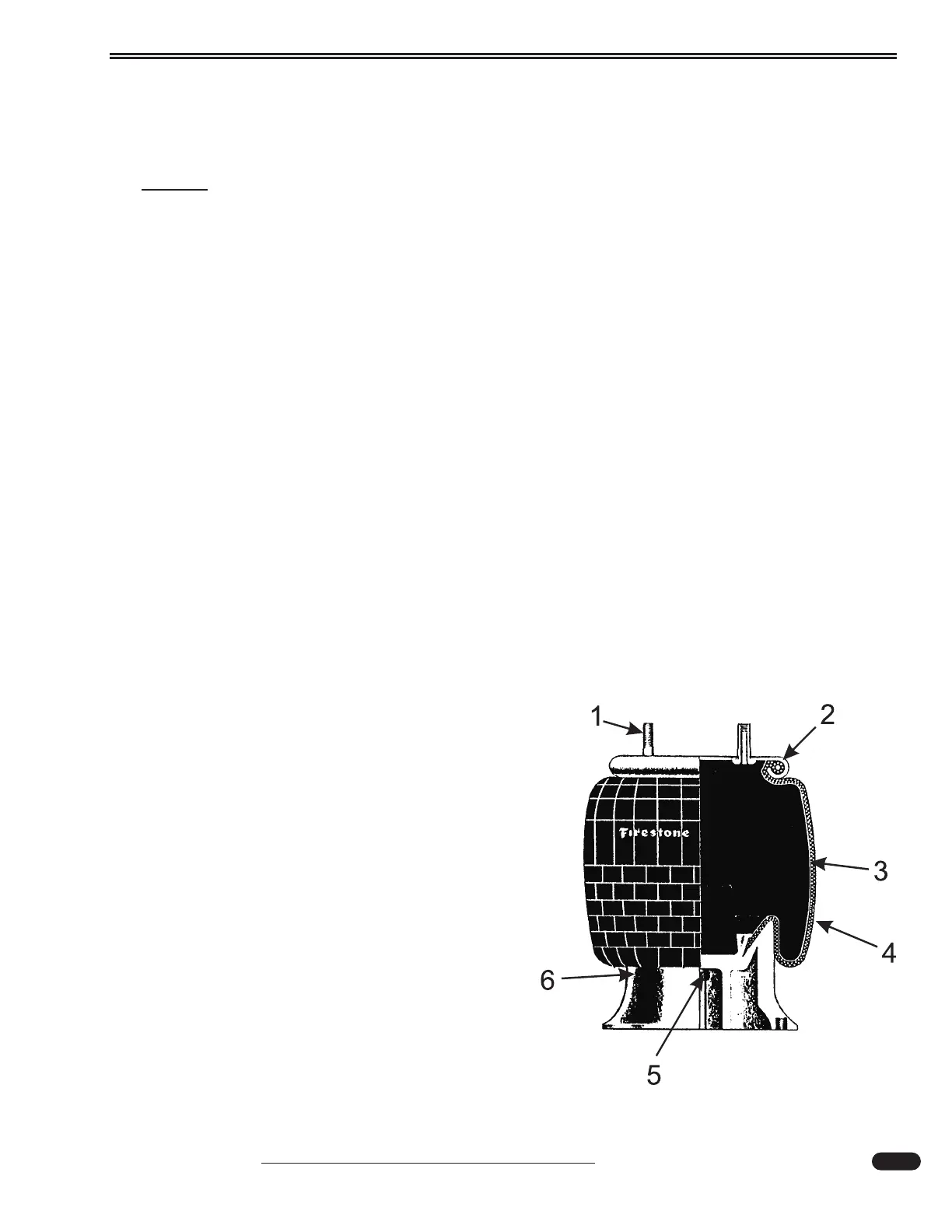

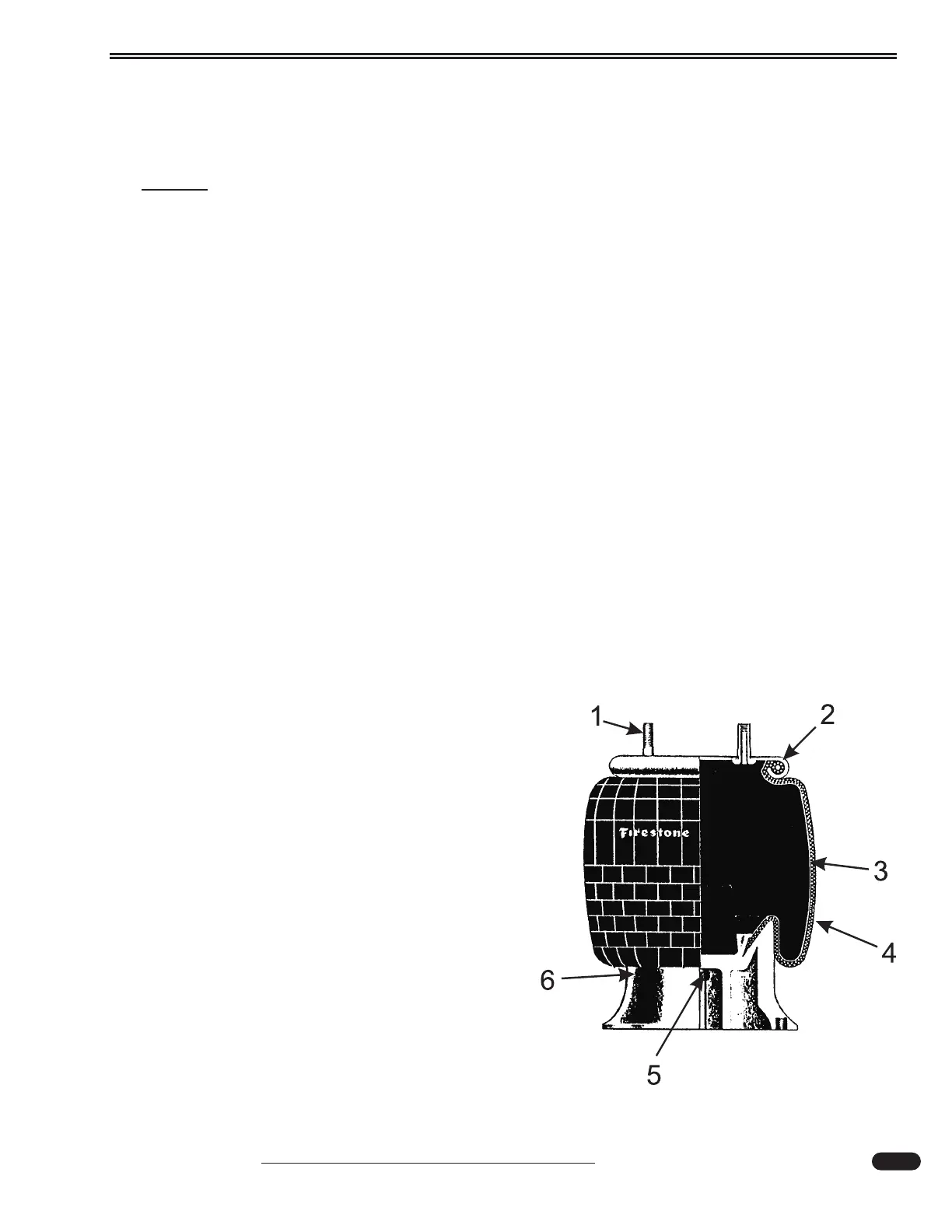

AIR SPRING INSPECTIONS

Listed below are items that can be checked when the motorhome is in for periodic maintenance.

NOTE:

Never attempt to service the air suspension on a motorhome with the “air spring”

inflated.

• Inspect the Outer Diameter (OD) of the air springs. Check for irregular wear or heat

cracking.

• Inspect the air lines to make sure contact does not exist between the air line and the OD of

the air springs. Air lines can rub a hole in an air spring very quickly.

• Check to see that there is sufficient clearance around the complete circumference of the air

spring while at maximum diameter.

• Inspect the OD of piston for buildup of foreign materials. (On a reversible sleeve style air

spring, the piston is the bottom component of the air spring.)

• The correct ride height should be maintained. All motorhomes with air springs have a

specified ride height established by the manufacturer. This height should be maintained

within ¼ ". This dimension can be checked with the motorhome loaded or empty.

• The leveling valves (or height control valves) assist in ensuring the total air spring system

works as required. Clean, inspect and replace if necessary.

• Make sure to check shock absorbers for leaking hydraulic oil and worn or broken end con-

nectors. If a broken shock is found, replace it immediately. The shock absorber will nor-

mally limit the rebound of an air spring and keep it from over extending.

• Check the tightness of all mounting hardware (nuts and bolts). If loose, tighten. Do not

over-tighten.

Cleaning:

The approved cleaning method is to use soap

and water, methyl alcohol, ethyl alcohol and iso-

propyl alcohol. Unapproved cleaning methods

include all organic solvents, open flames, abrasive

and direct pressurized steam cleaning.

090269

Loading...

Loading...