MASTER EJECT

C262/C265 6-28 SM

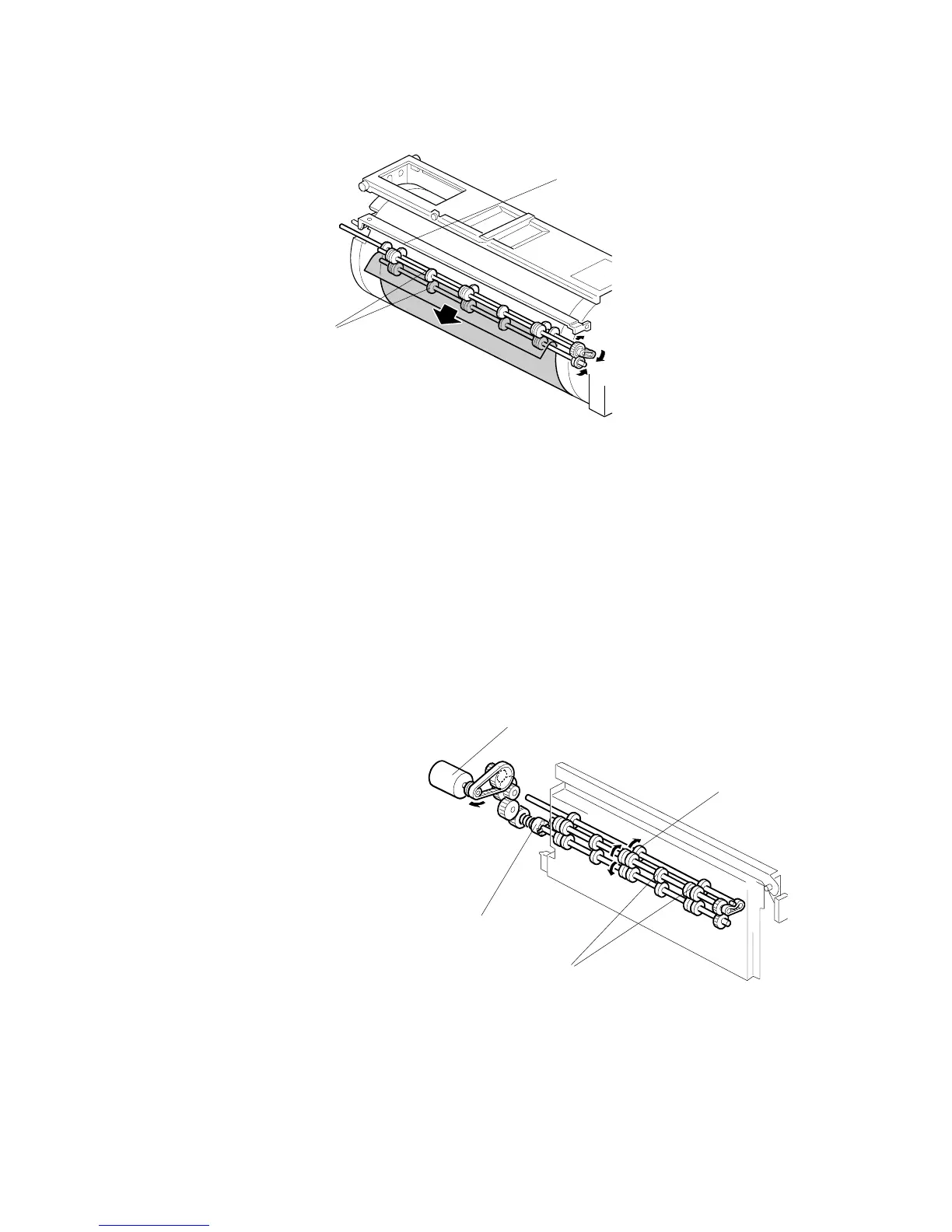

Master Eject and Transportation

The master pick-up roller [A] and the upper and lower master eject rollers [B] all

turn together. They start turning as soon as the drum reaches the master eject

position.

The rollers stop once the leading area of the master is picked up from the drum.

(The master eject sensor detects this.) Then, when the drum starts turning, they

turn on again to feed the ejected master to the eject box while the drum turns

towards the master making position.

The master eject sensor (not shown) is located just under the lower master eject

roller, and it monitors the master feeding. If the master is not properly picked up, i.e.

it does not activate the sensor; the operation panel displays a master eject jam

message.

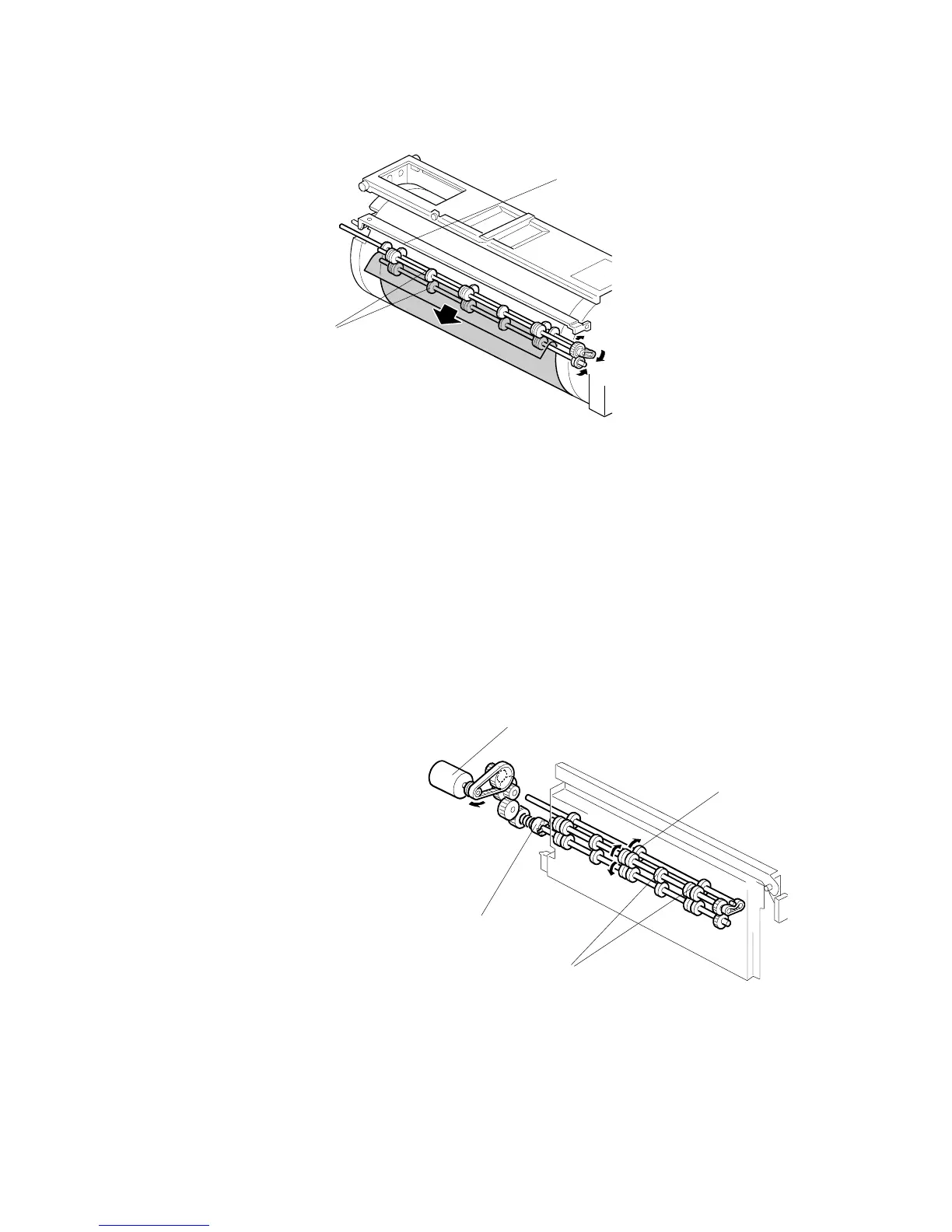

Master Eject Roller Unit

Drive

The master eject motor [A turns

the master pick-up roller [B with

the upper and lower master

eject rollers [C.

When the unit is slid out

(explained below), the joint [D]

disengages.

C262D016.WMF

C262D513.WMF

[A]

[B]

[A

[B]

[D

[C]

Loading...

Loading...