TestProcedure

Thechargepressuretestistherstinaseriesoftestsrecommendedto

determinetractioncircuitperformance.Achargepressuredropofmorethan

20%whenamoderateloadisplacedonthepiston(traction)pumpindicates

aninternalleakinthepiston(traction)pump.Reducedchargepressuremay

alsoindicateafaultyreliefvalve(R4)inthesteeringcontrolunit.Continued

unitoperationcangenerateexcessiveheat,causedamagetosealsandother

componentsinthehydraulicsystem,andaffectoverallmachineperformance.

SpecialEquipmentRequired:

•PressureGauge(accuratebelow300psi)withhoseandquickdisconnect

coupling

•Flowmeterwithpressuregaugethathasatleasta114L/minute(30

gallons/minute)capacity.

•2HydraulicHoses

1.Parkthemachineonalevelsurface,lowerthecuttingunit(orattachment),

andsetthekeyswitchtotheOFFposition.

2.ReadandadheretotheinformationprovidedinT estingtheHydraulicSystem

(page5–22).

3.EnsurethatthetractionpedaliscorrectlyadjustedfortheNEUTRALposition;

refertoAdjustingtheTractionSystemforNeutral(page5–50).Also,ensure

thatthehydraulicpumpisatfullstrokewhentractionpedalispressedfullyin

forwardposition.

4.Connectahydraulicpressuregaugetothediagnosticttingatthemain

hydraulicmanifoldG2port.

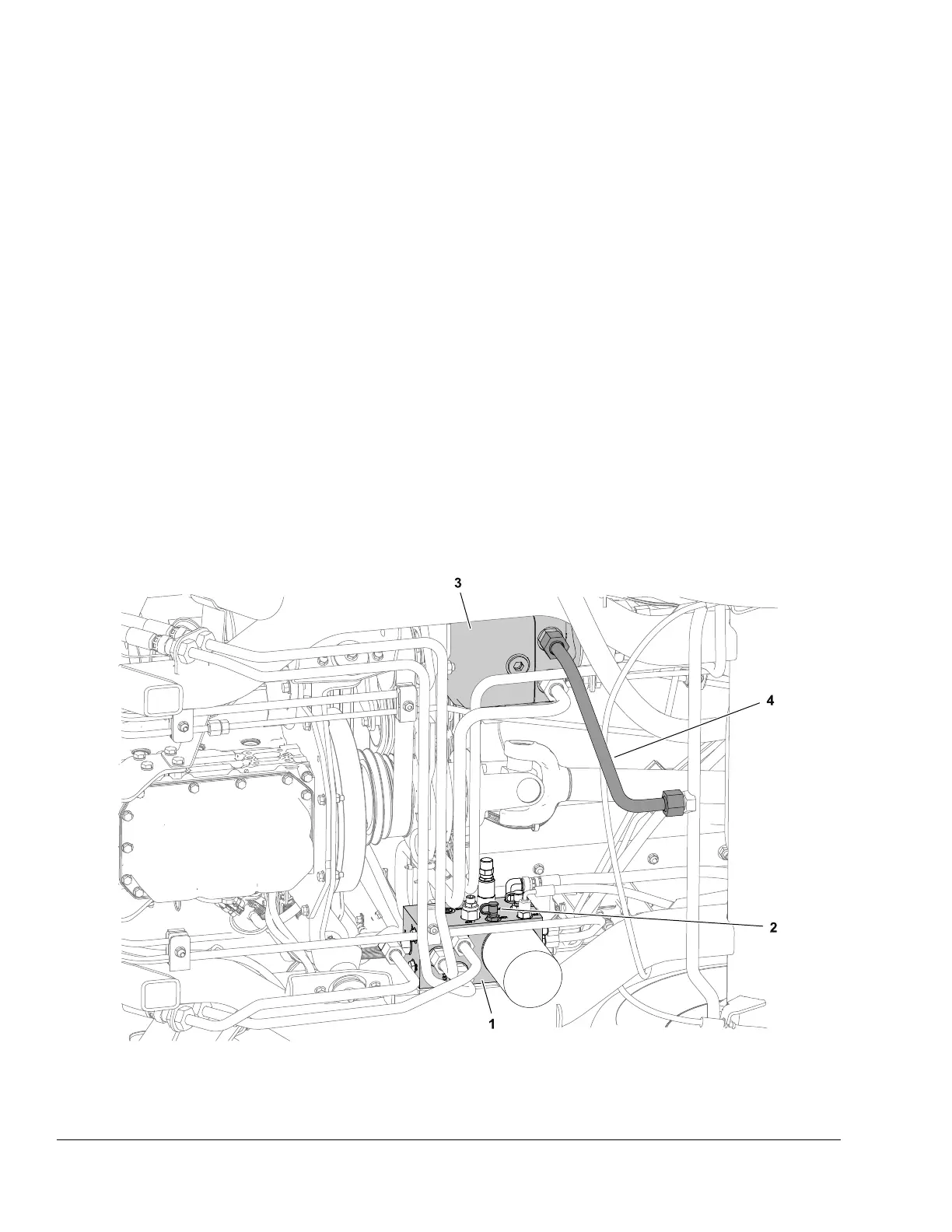

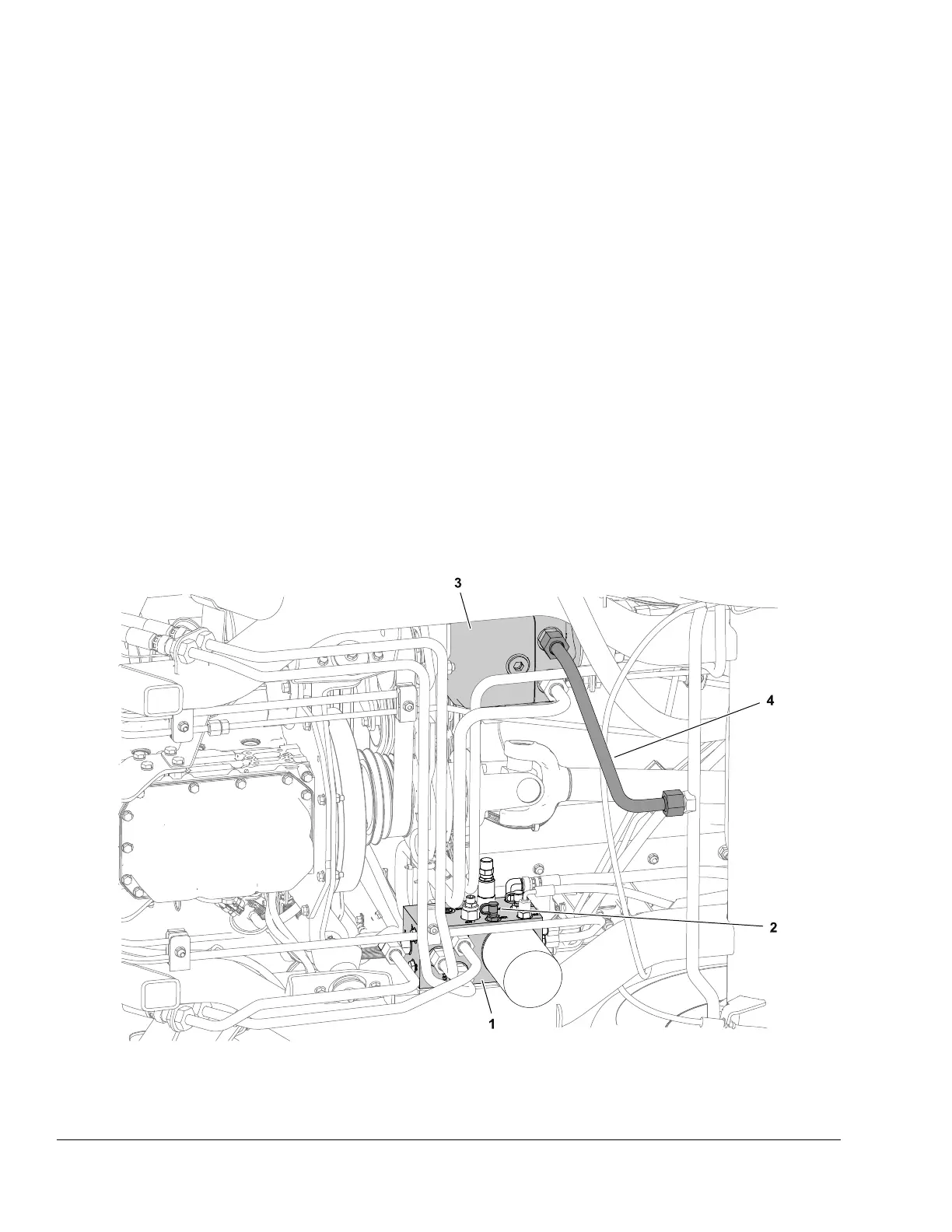

g299124

Figure29

1.Mainhydraulicmanifold3.Hydraulicpump(P1)

2.Diagnostictting–G2port

4.Hydraulictube

HydraulicSystem:TestingtheHydraulicSystem

Page5–26

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...