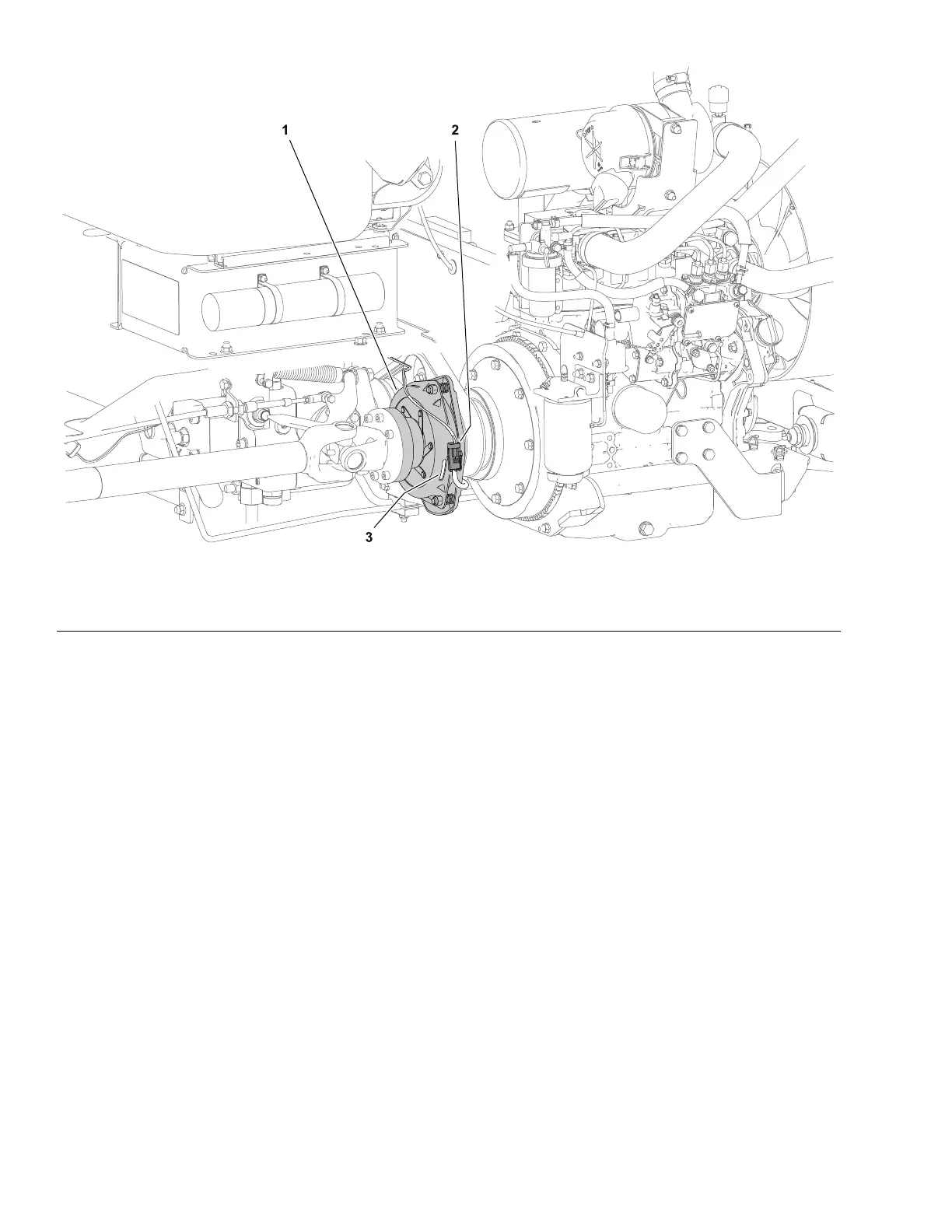

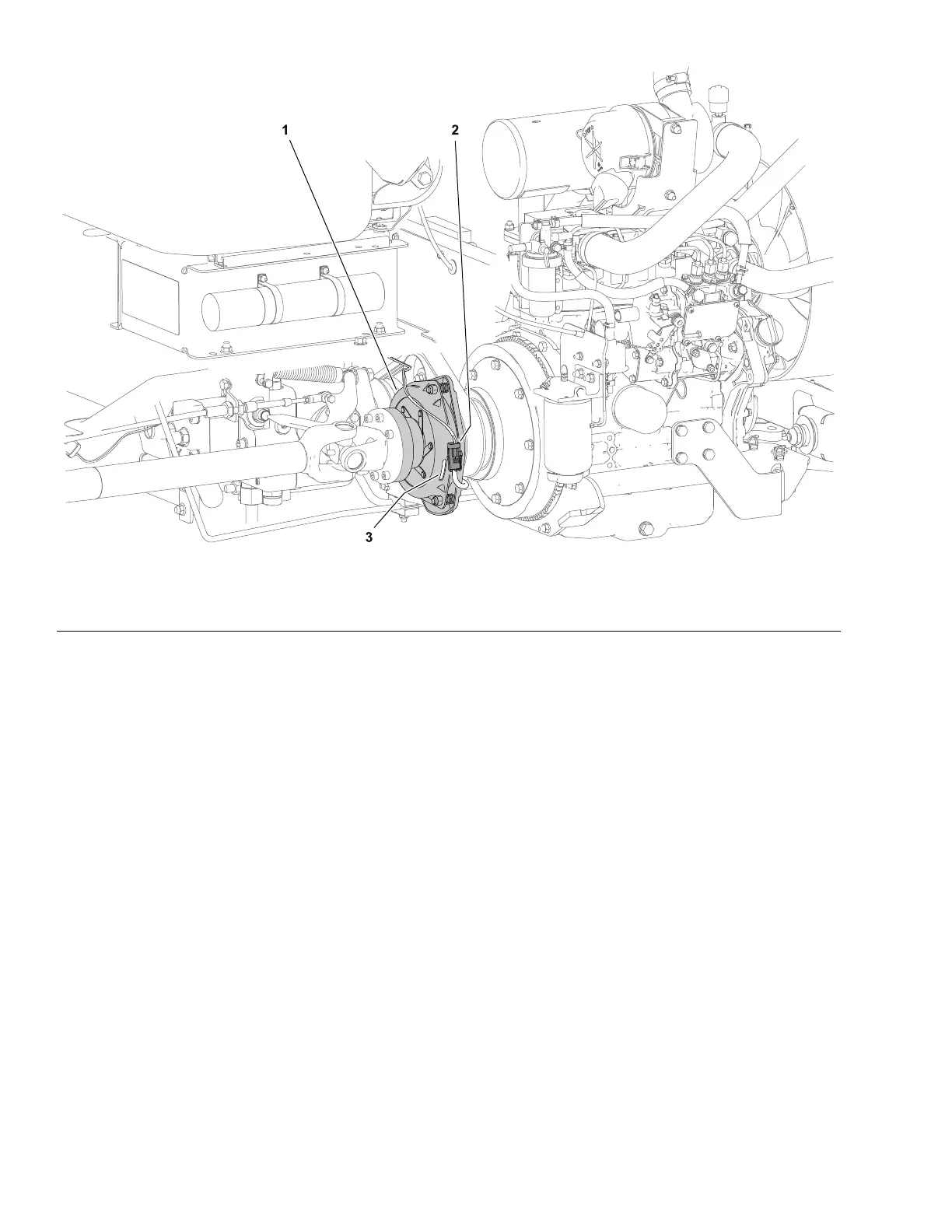

PTOClutch

g306981

Figure99

1.PTOclutch

2.Wireharnessconnector

3.Accessslot(3each)

AnelectricclutchisusedtoengagethePTO.Theelectricclutchismountedon

theenginecrankshaftandengageswhencurrentisappliedtotheclutchcoil.

Theclutchalsoincorporatesamagneticbraketostopclutchrotationwhenthe

clutchisde-energized.ForPTOclutchadjustmentinformation,refertoAdjusting

thePTOClutch(page7–4).

TestingthePTOClutch

1.Parkthemachineonalevelsurface,lowerthecuttingunit(orattachment),

engagetheparkingbrake,setthekeyswitchtotheOFFpositionandremove

thekeyfromthekeyswitch.

2.Unplugtheclutchelectricalconnectorfromthemachinewireharness.

Checktheharnessconnectorsfordamageorcorrosionandcleanorrepair

ifnecessary.

Note:Priortotakingsmallresistancereadingswithadigitalmultimeter,short

themetertestleadstogether.Themeterwilldisplayasmallresistancevalue

(usually0.5ohmsorless).Thisresistanceisduetotheinternalresistanceof

themeterandtestleads.Subtractthisvaluefromthemeasuredvalueofthe

componentyouaretestingtoobtainanaccuratereading.

3.Useamultimeter(ohmssetting),checktheclutchcoilresistanceacrossthe

twoclutchconnectorterminals.Thecoilresistanceshouldbeapproximately

2.2ohmswhentestedat20°C(68°F).Checkthatthereisnocontinuity

betweeneitheroftheclutchterminalsandtheclutchframe.

4.Apply12VDCtotheterminalsofthePTOelectricclutch.Thecoilshould

energizeandtheclutchshouldengage.

ElectricalSystem:TestingtheElectricalComponents

Page6–48

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...