CANbus

ThemachinecontrollerscommunicatewitheachotheronaControllerArea

Network(CAN)bussystem.Usingthisnetworkallowsfullintegrationofallthe

differentelectricalcomponentsofthemachine,allowingthemtooperatetogether

asone.TheCANbussystemreducesthenumberofelectricalcomponentsand

connectionsusedonthemachineandallowsthenumberofwiresinthewire

harnesstobesignicantlyreduced.

Formodel31900,31901,31907and31909machines,theTDMcontrolleristhe

onlycontrollerontheCANbuspresently.Formodel31902and31903machines,

theTDMcontrollerandtheYanmarengineECUaretheonlycontrollersonthe

CANbuspresently.Additionalcontrollers(forattachments)maybeadded

totheCANbusinthefuturethroughtheexpansionportconnectorand/orthe

telematicsconnector.

EachofthecomponentsthatiscontrolledbytheCANbuslinkonlyneedsfour

(4)wirestooperateandcommunicatetothesystem:CANHigh,CANLow,

powerandground.ThekeyswitchneedstobeintheRUNorSTARTposition

forthecomponentsonthenetworktobeactivated.

Twospeciallydesigned,twistedwiresformtheCANbus.Thesewiresprovidethe

datapathwaysbetweenthecomponentsonthenetwork.Theengineeringterm

forthesecablesareCANHighandCANLow.TheCANbuswiresarered/white

(CAN-High)andblack/white(CANLow).AteachendoftheCANbusisa120

ohmterminationresistor;refertoCANbusT erminatorResistors(page6–56).

TestingtheCANbus

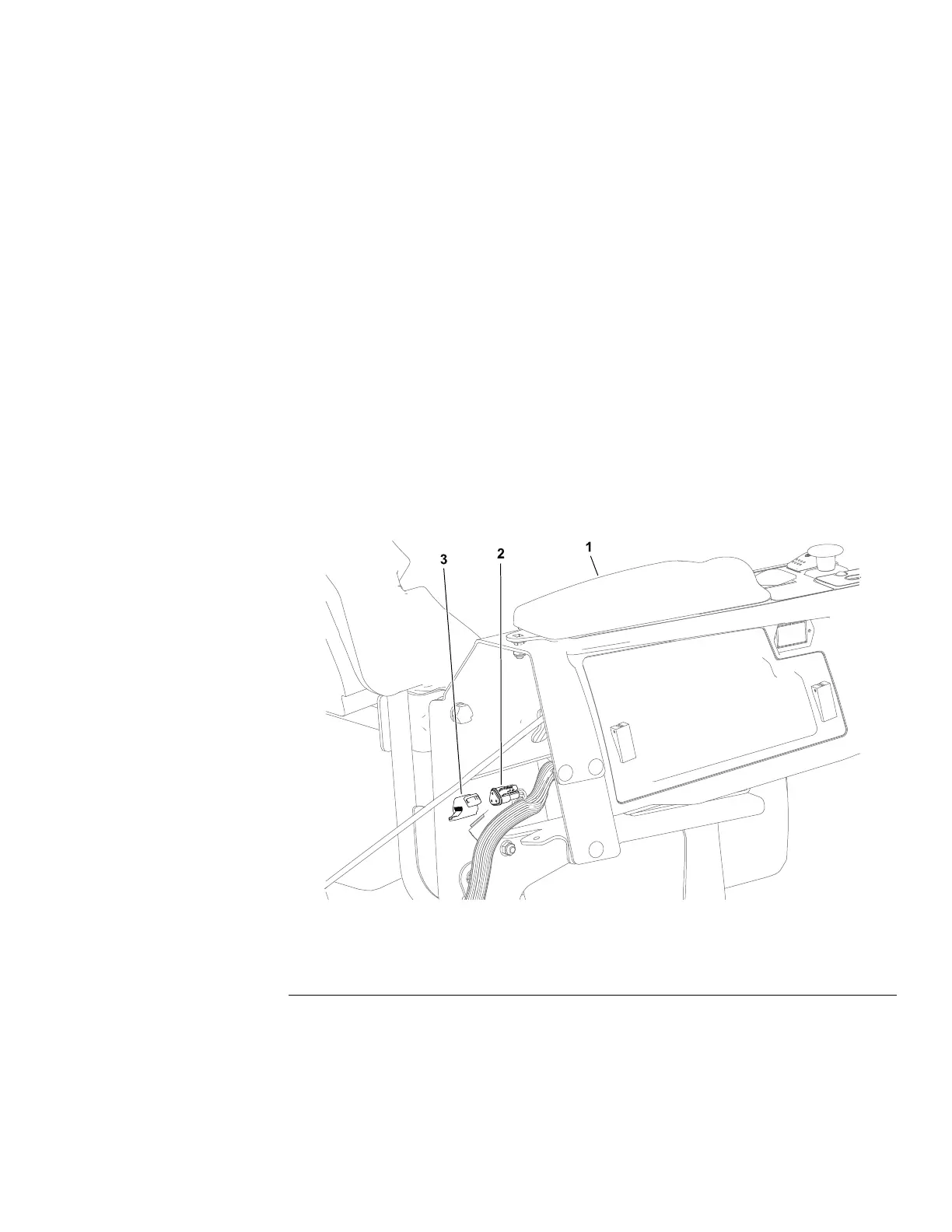

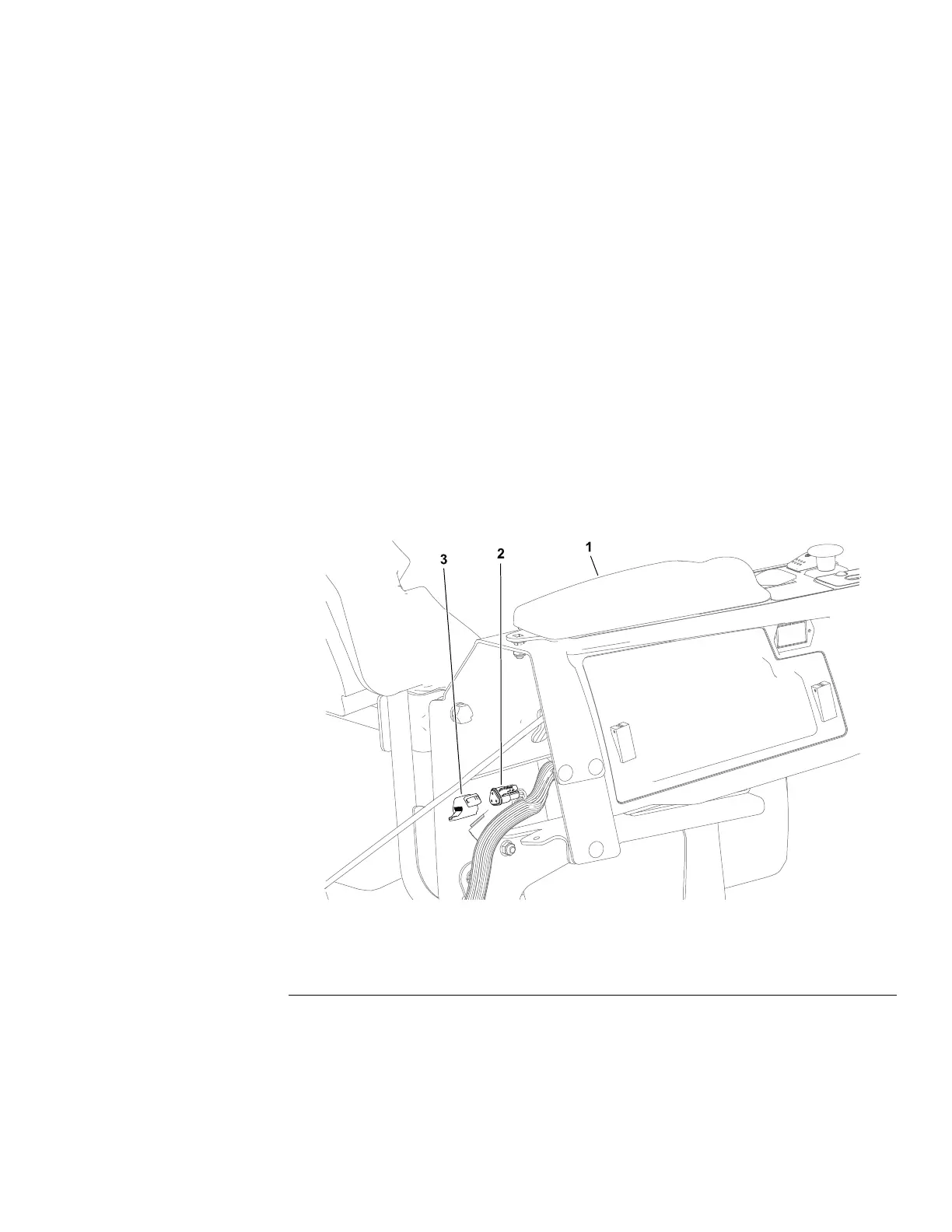

g305596

Figure84

1.Operator’sconsole3.Cover

2.DIAGconnector

1.Parkthemachineonalevelsurface,lowerthecuttingunit(orattachment),

engagetheparkingbrake,setthekeyswitchtotheOFFpositionandremove

thekeyfromthekeyswitch.

2.TheT oroDIAGconnectorispartoftheCANbusandislocatedattherear

oftheoperator’sconsole.Removetheconnectorcoverfromthemachine

wireharnessanduseamultimeter(ohmssetting)tochecktheT oroDIAG

connector.

Groundsmaster

®

3200,3300and3310

Page6–17

ElectricalSystem:TestingtheElectricalComponents

19240SLRevA

Loading...

Loading...